Share

Read Next

Additive manufacturing is going to bring new possibilities to power generation systems. Complex 3D printed component geometries promise to deliver both increased power efficiency and reduced manufacturing cost. But when it comes to the kinds of systems that provide safe, reliable power to communities and industrial facilities, AM is being asked to deliver on the old possibilities first. In two different applications — involving gas turbines and nuclear power — Oak Ridge National Laboratory’s Manufacturing Demonstration Facility (MDF) has produced 3D printed components to conventionally manufactured part designs and specifications, so these components can prove their effectiveness for established uses before AM is leveraged to pursue design changes.

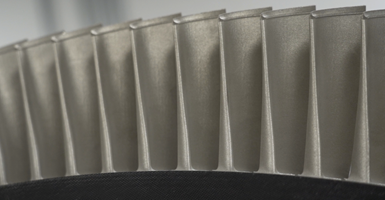

The MDF made hundreds of turbine blades through EBM for Solar Turbines' testing of 3D printed turbine blade performance.

The gas turbine application is a collaboration with turbine manufacturer Solar Turbines. The MDF manufactured nearly 300 turbine blades through electron beam melting on machines from Arcam (GE Additive) for evaluation in Solar Turbines’ test platform. The blade design is conventional, including the established material: Inconel 738. The alloy is challenging to 3D print, necessitating the high temperature of EBM. Future turbine blades designed for AM presumably might use a different alloy.

The design is not complex but the promise is great. A set of 3D printed stainless steel brackets like this one is currently in operation in a nuclear reactor. They will help validate the use of AM for manufacturing reactor components.

For nuclear power, Oak Ridge partnered with nuclear power industry manufacturer Framatome to make a set of 316 stainless steel brackets through laser powder bed fusion on a machine from Concept Laser (also GE Additive). The brackets help to secure a nuclear fuel assembly within the Browns Ferry nuclear power plant in Alabama. Their evaluation will come in 2027, after they have operated for six years, when the brackets will be removed and sent back to Oak Ridge for examination.

The fundamental question in both cases is: Can power-system OEMs be assured that metal parts made via additive manufacturing are just as reliable and stable as metal parts made through the production processes we are used to?

The long-term promise justifies the exploration. Oak Ridge Research Materials Scientist Mike Kirka has been involved in the turbine blade work. With AM, he says, turbine makers will be able to “open up new design paradigms for more efficient cooling schemes that would allow turbine blades in the hot section of the engine to run much hotter while being [internally] cooled. This would have multiple impacts, from the energy efficiency of the engines themselves to potentially more resilient components with longer service lives.”

Deposition Science and Technology Group Leader Ryan Dehoff of Oak Ridge worked on the nuclear bracket. “A nuclear reactor is essentially a very large-scale heat exchanger. Additive enables us to print very complex designs,” he says, for more effective heat transfer. “I think that there could be a very large impact from additive manufacturing technologies inside the nuclear industry. The challenge is we have to certify and qualify the components.”

Turbine Blades and Nuclear Brackets on The Cool Parts Show

Both of these applications have been covered in episodes of The Cool Parts Show, where we explore in more detail the 3D printing and machining needs of each part:

3D Printed Turbine Blades for More Efficient Power Generation: The Cool Parts Show #35

3D Printed Brackets Secure Fuel for Nuclear Power: The Cool Parts Show #45

Related Content

DOE Awards Nearly $3 Million to Develop Additive Manufacturing of Modular Wind Blades

The industry partners received the award to develop automation in additive manufacturing of tooling for large-scale wind blades that can accommodate continuous changes in blade geometry and scale.

Read More3D Printed Reactor Core Makes Solar Fuel Production More Efficient

The solar reactor uses water and CO2 from the air and sunlight as the energy source to produce carbon-neutral liquid fuels, for example, solar kerosene for aviation.

Read MoreBaker Hughes Successfully Implements Oqton Manufacturing OS System to Optimize Additive-Driven Manufacturing Workflow

3D Systems say this successful implementation demonstrates its Oqton Manufacturing OS’ ability to accelerate the design and production of additively manufactured parts across the entire manufacturing workflow to increase efficiency and facilitate regulatory compliance.

Read MoreVideo: 5" Diameter Navy Artillery Rounds Made Through Robot Directed Energy Deposition (DED) Instead of Forging

Big Metal Additive conceives additive manufacturing production factory making hundreds of Navy projectile housings per day.

Read MoreRead Next

Video: What is the Manufacturing Demonstration Facility at Oak Ridge National Laboratory?

This industry-focused organization within the Department of Energy helps manufacturers make use of advanced technology, particularly 3D printing. One of the group’s leaders describes how companies work with the MDF.

Read More3D Printed Turbine Blades for More Efficient Power Generation: The Cool Parts Show #35

Blades made through additive manufacturing promise to let turbines run hotter, and therefore generate more power without increasing in size.

Read More3D Printed Brackets Secure Fuel for Nuclear Power: The Cool Parts Show #45

Can additive manufacturing improve the design of nuclear power plants? These steel brackets are the first step.

Read More