3D Printed Reactor Core Makes Solar Fuel Production More Efficient

The solar reactor uses water and CO2 from the air and sunlight as the energy source to produce carbon-neutral liquid fuels, for example, solar kerosene for aviation.

Using a new 3D printing technique, researchers at ETH Zurich have developed special ceramic structures for a solar reactor. Initial experimental testing show that these structures can boost the production yield of solar fuels.

In order to make air travel more environmentally friendly, intensive research is being conducted into sustainable fuels. In recent years, ETH researchers have developed a technology that enables the production of a carbon-neutral liquid fuel from sunlight and air. The centerpiece of this technology is a solar reactor capable of splitting CO2 and water, which had previously been extracted from the air.

The researchers have devised a 3D printing method for creating the ceramic structures of the solar reactor. This enables more efficient transport of solar radiation into the reactor, thereby doubling the fuel production capacity.

In 2019, the researchers demonstrated the entire thermochemical process chain under real conditions for the first time, in the middle of Zurich, on the roof of the ETH Machine Laboratory. These synthetic solar fuels are carbon neutral because they release only as much CO2 during their combustion as was drawn from the air for their production. Two ETH spinoffs, Climeworks and Synhelion, are further developing and commercializing the technologies.

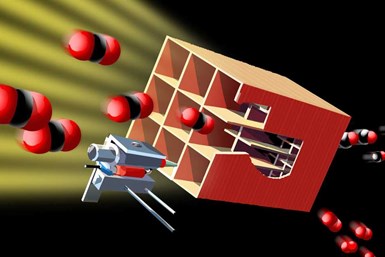

At the heart of the production process is a solar reactor that is exposed to concentrated sunlight delivered by a parabolic mirror and reaches temperatures of up to 1,500°C. Inside this reactor (which contains a porous ceramic structure made of cerium oxide), a thermochemical cycle takes place for splitting water and CO2 captured previously from the air. The product is syngas — a mixture of hydrogen and carbon monoxide, which can be further processed into liquid hydrocarbon fuels such as kerosene (jet fuel) for powering aviation.

Until now, structures with isotropic porosity have been applied, but these have the drawback that they exponentially attenuate the incident solar radiation as it travels into the reactor. This results in lower inner temperatures, limiting the fuel yield of the solar reactor.

Now, researchers from the group of André Studart, ETH professor of complex materials, and the group of Aldo Steinfeld, ETH professor of renewable energy carriers, have developed a novel 3D printing methodology that enables them to manufacture porous ceramic structures with complex pore geometries to transport solar radiation more efficiently into the reactor’s interior. The research project is funded by the Swiss Federal Office of Energy.

The researchers say that hierarchically-ordered designs with channels and pores that are open at the surface exposed to the sunlight and become narrower towards the rear of the reactor have proven to be particularly efficient. This arrangement enables the reactor core to absorb the incident-concentrated solar radiation over the entire volume. This in turn ensures that the whole porous structure reaches the reaction temperature of 1500°C, thereby boosting the fuel generation.

These ceramic structures were manufactured using an extrusion-based 3D printing process and a new type of ink with optimal characteristics developed specifically for this purpose, namely low viscosity and a high concentration of ceria particles to maximize the amount of redox active material.

Successful Initial Testing

The researchers investigated the complex interplay between the transfer of radiant heat and the thermochemical reaction. They were able to show that their new hierarchical structures can produce twice as much fuel as the uniform structures when subjected to the same concentrated solar radiation of intensity equivalent to 1,000 suns.

The technology for 3D printing the ceramic structures is already patented, and Synhelion has acquired the license from ETH Zurich. “This technology has the potential to boost the solar reactor’s energy efficiency and thus to significantly improve the economic viability of sustainable aviation fuels,” Steinfeld says.

- Read how researchers at ETH Zurich developed a set of design heuristics specific to additive manufacturing for creating card decks that help people be more creative with AM.

- Learn how 9T Labs (a spinoff from ETH Zurich) uses fiber-reinforced 3D printing to expand control and applications for composites. 9T Labs’ deposition process places continuous carbon fiber only where necessary to save material, reduce waste and more precisely control the structure of preform composites.

Related Content

MoldJet Technology Enables High-Throughput Metal, Ceramic Additive Manufacturing

Formnext 2023: Tritone Technologies’ additive manufacturing solutions enable industrial throughput of accurate parts with a range of metal and ceramic materials.

Read More8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreAM 101: What Is Binder Jetting? (Includes Video)

Binder jetting requires no support structures, is accurate and repeatable, and is said to eliminate dimensional distortion problems common in some high-heat 3D technologies. Here is a look at how binder jetting works and its benefits for additive manufacturing.

Read MoreBMF Receives FDA Clearance for UltraThineer Dental Veneer Material

The zirconia materials are now qualified for use in the production of the world’s thinnest cosmetic veneers, which require significantly less tooth preparation or grinding, thereby preserving more of the patient’s natural enamel.

Read MoreRead Next

3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read More