Additive Manufacturing and Measurement Interconnect — Each Enables the Other to Advance

Measurement aids AM and AM aids measurement. Recently posted articles describe how sensing and measurement make AM more capable, while AM delivers devices that are smarter because of sensing.

The future is so bright, I’ve got to wear shades precisely customized to fit my face. Measurement is as important as AM in realizing products such as this.

In our coverage of additive manufacturing (AM) technology and its applications, we frequently try to look for big-picture themes. For example, we’ve done issues of our print magazine focused on production, on materials, and on the link between AM and robots. Recent articles we’ve posted build toward a theme that is perhaps the most subtle we’ve ever explored, as well as potentially the most transformative. That topic is the interrelationship between additive manufacturing and measurement.

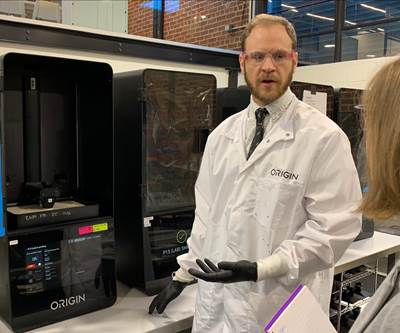

AM is a process like no other, creating needs for measurement beyond what conventional manufacturing processes require or could even make use of. To appreciate this, start with our article on polymerization within the 3D printing build. Additive is unlike other processes because it creates the inner material properties at the same time as the outer geometric form, with one affecting the other as the part takes shape. Measuring more of the variables within this complex process to realize “more knobs to turn” (as the article says) provides a greater scope of possibility for both process and part — including, in this case, the chance to print a plastic part with no need for subsequent curing. A similar idea, expanded possibilities from measuring process variables, applies to metal AM as well. Indeed, advancing metal AM is the very aim of one university’s substantial investment in measurement technology.

But there is far more. As measurement is helping AM realize its promise, AM is returning the favor. Together, 3D printing and sensing devices will help deliver on the possibilities of an interconnected world. To get a sense of this, look to this item on additive and the Internet of Things (IoT). A solid-state 3D printing process can make solid parts “smart” because of the sensing embedded inside. The article identifies one application: the chance to monitor oilfield components that report their own status while in use. But imagine how different our world might be when this kind of embedded measurement and self-reporting capability within parts becomes commonplace. We are accustomed to the objects around us all being separate and senseless; what happens when they can communicate their needs, and even better, respond to ours? I am sure I cannot envision all the possibilities that might come of widespread interconnection enabled by AM, just as I am sure I also don’t know all the advances liable to come of the way AM is improving measurement for quantum physics.

Then there are the ways our lives as individuals and consumers will get better — with better products, tailored to us — not just because of 3D printing, but because of what 3D printing and measurement can do in tandem. Measurement systems are already aiding AM to deliver products like this, and the examples include dental appliances, footwear, and, perhaps my favorite, eyewear.

One last item captures this theme best of all: the smart build plate. This plate for AM was made by AM. 3D printing the plate made it possible to embed sensing, potentially making the additive build more efficient because the plate made smart in this way can detect build failure as it occurs. Here, then, is AM enabling measurement to enable AM. When we think about the advance of technology in terms of more responsive systems and machines, when we look to what it will take to realize this advance, part of what we see is the benefit to be won from AM and measurement continuing to advance together.

Related Content

This Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

Read MoreQuadrus: Powder Management Tactics for Tungsten Rhenium and Other AM Alloys

The expert in additive manufacturing of high-value parts for the Defense Department often must change from one exotic material to another in its powder bed machines. Cleaning is a core competency. Here are lessons of this company’s system for working with an ever-changing mix of 3D printed alloys.

Read MoreUnderstanding PEKK and PEEK for 3D Printing: The Cool Parts Show Bonus

Both materials offer properties desirable for medical implants, among other applications. In this bonus episode, hear more from Oxford Performance Materials and Curiteva about how these companies are applying PEKK and PEEK, respectively.

Read MoreFDA-Approved Spine Implant Made with PEEK: The Cool Parts Show #63

Curiteva now manufactures these cervical spine implants using an unusual 3D printing method: fused strand deposition. Learn how the process works and why it’s a good pairing with PEEK in this episode of The Cool Parts Show.

Read MoreRead Next

The Promise of Full Polymerization in Resin 3D Printing

Origin’s platform isn’t just another resin 3D printer based on digital light processing (DLP). Through hardware, software and material partnerships, the company is changing what is possible inside a photopolymerization printer.

Read MoreIs Solid-State Additive Manufacturing an Enabler to the Internet of Things?

Startup Tri-D Dynamics sees precision cold spray 3D printing providing IoT-enabled parts with electronics built in. The promise is sensing in environments where the sensing might be needed most.

Read MoreA $1.5 Million Dive into the Melt Pool

A new, customized digital radiology vault and specialized additive manufacturing system at Auburn University aims to understand and control the complex heat and mass transport phenomena taking place during the laser sintering process.

Read More