Is Solid-State Additive Manufacturing an Enabler to the Internet of Things?

Startup Tri-D Dynamics sees precision cold spray 3D printing providing IoT-enabled parts with electronics built in. The promise is sensing in environments where the sensing might be needed most.

Cold spray metal additive manufacturing is “robot intensive” says Deepak Atyam of Tri-D Dynamics. The startup’s recent work has focused on developing the programmed robot motion for precise 3D printed parts and features.

The idea of the Internet of Things (IoT) imagines a world in which devices provide data about their own performance, and interconnect with one another as part of a responsive network of hardware.

Could additive manufacturing (AM) be an enabler for achieving this?

Yes, provided the AM process is solid state. That is, provided the state of the material does not have to change between solid and liquid as a requirement of the 3D printing process. This is the advantage and the promise Tri-D Dynamics sees in cold spray metal AM. This process involves no melting, making it possible to build solid components and embed sensors and electronics within them during the course of the build. The California Bay Area startup expects soon to be able to offer rugged, solid, IoT-enabled components for harsh applications such as oil and gas extraction.

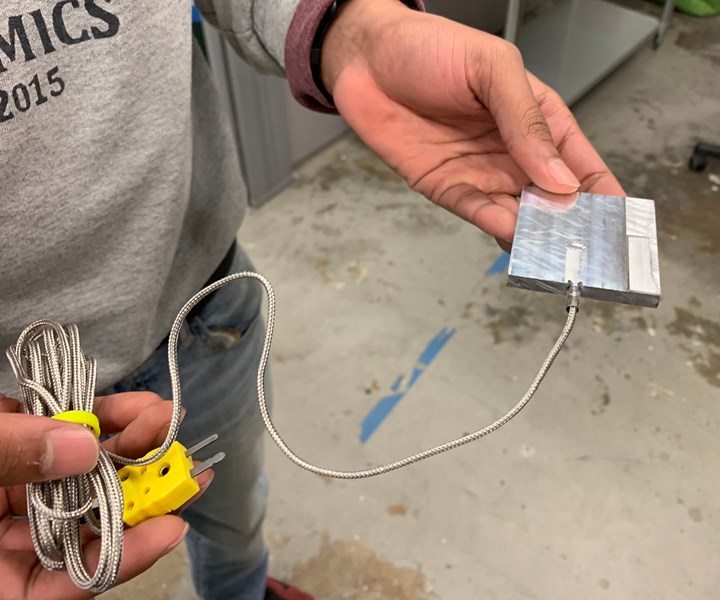

A simple demo of a sensor-embedded part. This solid aluminum plate contains a thermocouple. A slot was milled in the plate, the sensor was added, and cold spray was used to 3D print the part back to completion. Cold spray could also be used to build a more detailed part or feature, with the build paused midway so a sensor could be added, perhaps by the same robot performing the build.

Cold spray AM uses speed and pressure to bond metal powder. Without any melt pool to help the build flow into its final form and integrity, “this process is less forgiving than other metal additive approaches,” says Deepak Atyam, Tri-D Dynamics co-founder and CEO. As a result, the process is “robot intensive,” he says. The precision of the path of the robot in manipulating the cold spray nozzle is crucial to success. The company is currently learning how to attain fine precision in cold spray AM using robot programming via software from Autodesk.

The result will be a new possibility, he says: sensing that is ready for the Internet of Things in applications harsh enough they would have ruled out electronics until now.

“We are competing with adhesives,” he says. But what about everywhere glue can’t go?

“We are competing with adhesives,” he says. Gluing a sensor onto the machine component remains the cheapest and most obvious way to bring connectivity. But what about everywhere glue can’t go? “We can bring sensing to applications where abrasive, chemistry, salinity or some other challenge stands in the way.” Indeed, arguably these challenging applications are the ones liable to benefit most from the monitoring and responsiveness IoT can deliver. AM will bring connectivity not to where it can be glued on, but to where it really needs to go.

For another example of solid-state additive manufacturing producing a component with sensing built in, see this episode of The Cool Parts Show about a sensor-embedded AM build plate.

Related Content

-

3D Printed Capo for Banjo Made With Binder Jetting not MIM: The Cool Parts Show #74

New market, no mold tooling needed: Additive manufacturing via binder jetting enables a maker of guitar capos to expand to serve banjo players as well.

-

Fluent Metal Startup Launches With Focus on Liquid Metal 3D Printing

The company says its drop-on-demand technology can enable sustainable, production-grade additive manufacturing using high-value metal components.

-

Researchers Develop Resin for 3D Printing Implants for Cataracts, Other Eye Conditions

The ability to 3D print intraocular devices for treating cataracts and other eye conditions could significantly enhance eye care for patients by offering unparalleled levels of customization and design precision, potentially leading to better clinical outcomes.