3D-Printed Metal Device Makes ACL Knee Surgery More Accurate

Additive manufacturing made it possible to produce a medical tool that offers surgeons better control during ACL repair or replacement surgery.

We’ve all heard stories about athletes who have torn the anterior cruciate ligament (ACL) in their knees while playing a sport. It is a serious injury and the recovery process can be long and painful. Just the thought of it makes me cringe. The repair or replacement of that ACL requires the surgeon to first remove any remnants of the natural ACL where it was attached to the surface of the tibia (shin bone) and femur (thigh bone) then attach a replacement ligament (graft) that accurately mimics the path and positioning of the natural ACL. This is a winding and complicated pathway. To make the process less invasive and more accurate demands a procedure done with precision and a surgical tool offering control. Such a tool was not readily available until recently, and additive manufacturing made it possible.

This new tool is the two-piece Pathfinder System, which consists of the 3D-printed Pathfinder ACL Guide (see Figure 1 in the slideshow above) and a special 2.2 mm flexible guide pin (drill). The system was invented by Dr. Dana Piasecki, an orthopedic surgeon at OrthoCarolina, an independent academic orthopedics practice in Charlotte, North Carolina, who set out to modify the standard surgical treatment for ACL injuries by using a 3D-printed metal tool.

The key to this system is the Pathfinder ACL Guide, a tool shaped to allow the surgeon to manipulate the guide pin inside the knee without having to open up the knee or contort it to place the graft. It acts as an extension of the surgeon’s hand, with the flexibility of the guide pin and the tight grip of the tool providing the surgeon with control over what he or she is trying to do inside the knee.

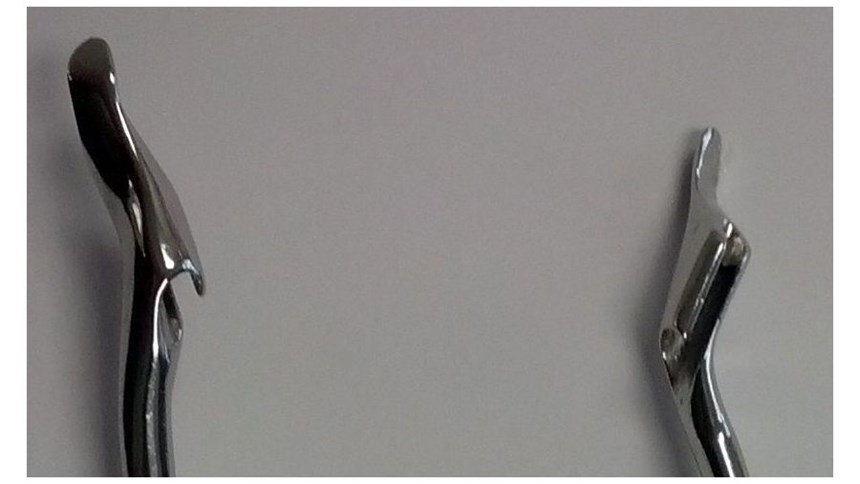

Ninety-five percent of the guide is the shaft, which is relatively simple. From the neck of the device to the critical tip is where all the design emphasis goes (see Figure 2). “The shape and tolerances are critical for this feature because of the way it follows the ligament’s normal path to impact the femur at the location and angle that anatomically mimics native ACL positioning,” explains John Self, project engineer for Stratasys Direct Manufacturing, which actually built the device using direct metal laser sintering (DMLS). “It also grasps the flexible guide pin, steers it to the proper spot on the femur and holds it during the drilling process.”

Creating the correct angle for the device tip through traditional manufacturing methods, such as machining it from a block, would require many setups, a lot of angles and undercuts, longer machining time, more material, and a higher overall cost. DMLS technology using Inconel 718 allowed the tip to be built at the specific angle necessary and at different build orientations without any machining (see Figure 3).

“Above all, it is a control issue, and that is what makes it a complex design that only AM can produce at an affordable price and offer the freedom necessary to make design changes on the fly,” says Jim Duncan, Dr. Piasecki’s business partner and CEO of DanaMed Inc., the medical device company founded to develop and produce the Pathfinder System.

Method and Material

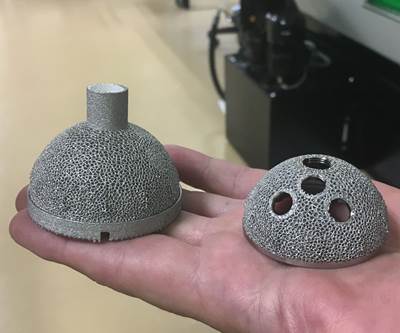

Additive manufacturing played a role in this collaborative project right from the outset when Minneapolis, Minnesota-based Laser Design, a provider of 3D laser scanning equipment and services, was hired to scan Dr. Piasecki’s first concepts and create a 3D CAD model. Once created, Laser Design turned to Stratasys Direct Manufacturing to produce physical, 3D-printed prototypes. Using fused deposition modeling (FDM), it produced 20 iterations of PC-ISO thermoplastic prototypes to prove out some initial design concepts. Because the device would be classified as a Class 1 surgical tool, one that carries a low risk of bodily contamination, Stratasys Direct Manufacturing then moved on to metal prototyping, using Inconel 718 and DMLS with a focus on the part’s required size, strength, shape and shine—all critical factors.

Size. The tip of the device is precisely sized in 5.5- and 7-mm versions to capture the guide pin and reference the back of the femur, ensuring the 2.2-mm pin is steered to the center of the native ACL footprint. DMLS could fabricate the varying sizes of features over the entire tool design in one piece.

Strength. Because the device would operate in the knee through a constraining hole approximately 5/8 inch in diameter, it had to be strong enough to hold a spinning guide pin as it drills into the femur without allowing it to move off center. Inconel’s density provided the necessary balance of strength and weight to help the surgeon control the tip when the device is held in his or her hand. A solid handle built as one piece instead of with a replaceable head also helped to provide the desired balance and control.

Shape. It was critical that the shape of the tool match the anatomy of the knee. Self describes the organic design: “It featured an elongated, slim body section; a slotted groove for capturing and holding a 2.2-mm diameter flexible guide pin and for easily disengaging with a simple twist of the tool; a curvilinear head section that would enable the surgeon to reference inner knee surfaces, turn and manipulate easily within the limited space, and rigidly hold position against bending and drilling forces; and an ergonomic handle.”

Shine, in this case, refers to the look, feel and maintenance of a surgical device, and it is achieved through post-processing after the part has been built through DMLS. Once taken out of the machine, supports are removed and the parts are bead-blasted to remove the surface layer. They are then shined via hand polishing. Polishing also closes off the surface and ensures that the part can withstand staining and cleaning. For the Pathfinder, this cleaning means a lot of sterilizing with hot and cold steam, and repeated washing with a relatively strong solution throughout its lifetime.

Let the Fine-Tuning Begin

Critical to the success of the project was having all parties involved understand the part’s critical surfaces, cooling of the sintered metal and required testing to ensure dimensions are met. All of that takes a lot of fine-tuning of design and processes, and AM makes this fine-tuning easier.

In general, DMLS allowed Dr. Piasecki’s design changes to be quickly and easily implemented. “All he had to do was provide a new model,” Self says. “We do the setups and changes and share the data, he validates the changes and tells us if it is a quality change he wants to keep or return to a previous version.” DMLS also has allowed for left-hand and right-hand versions of the tool, and 5.5- and 7-mm versions that did not require tooling or additional build-setup fees.

Stratasys Direct Manufacturing never built the same prototype twice, but AM allowed them to be built fairly quickly. On average, it took 12 days to build each new design variation, and the company delivered 22 prototypes over 10 months.

Additive also allowed for adjustments after the prototyping stage. Five out of the six initial test production parts were rejected for dimensional inaccuracies, so adjustments were made to compensate for dimensional changes that occur as the metal cools. Stratasys Direct Manufacturing learned that it needed to offset for the heat shrinkage that takes place during cooling, so it worked to find a build orientation that would provide the least amount of distortion when it cooled and wouldn’t degrade the tip (see Figure 4). Also through design modifications, Laser Design and Stratasys Direct Manufacturing identified process controls to reach a repeatable design within a ±0.005-inch tolerance. Then Laser Design adjusted the design to account for size reduction during cooling and polishing.

Stratasys Direct Manufacturing also worked with Dr. Piasecki to redesign the handle of the tool to round the sharp edges of grooves intended for grip and stability, which required a lot of labor to dig out the supports and polish (see Figure 5).

To finish the parts, Stratasys Direct Manufacturing removes them from the build platform, polishes each piece and sends them to Laser Design to be laser-etched with identification numbers, and labels that identify left and right knees and the size of the knee to be operated on.

For dimensional testing, Stratasys Direct Manufacturing used laser sintering to build custom Nylon 12 PA fixtures to fit-check completed parts and confirm tolerances. These custom fixtures also ensure consistency and are part of the quality control process before parts are sent out the door.

To date, there are about 28 Pathfinders in service at approximately 12 different hospitals and clinics in the United States that have used the devices to complete more than 500 successful ACL reconstruction surgeries. Improvements and quality are ongoing efforts, as DanaMed continues to receive feedback from surgeons using the device.

“Being able to make design changes and 3D print new tools within days was essential in perfecting the Pathfinder’s design,” Duncan says. “We were able to get feedback from a surgeon, make design adjustments and send an updated Pathfinder within a week. That would not be possible with investment casting or injection molding.”

Although just one small feature on this surgical tool made it extremely complicated to produce, DMLS made that complex design a reality.

Related Content

Additive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

Read MoreVideo: 5" Diameter Navy Artillery Rounds Made Through Robot Directed Energy Deposition (DED) Instead of Forging

Big Metal Additive conceives additive manufacturing production factory making hundreds of Navy projectile housings per day.

Read MoreRead Next

3D-Printed Medical Drills Keep Bone Cool During Surgery

Drills made via additive manufacturing cut bones without causing thermal-induced damage thanks to internal cooling channels.

Read MoreEnd-to-End Additive Manufacturing at Slice Mfg. Studios

The Akron-based company aims to control and perfect the additive manufacturing of medical devices, from raw material all the way through shipping.

Read MoreHow Avid Product Development Creates Efficiencies in High-Mix, Low-Volume Additive Manufacturing

Contract manufacturer Avid Product Development (a Lubrizol company) has developed strategies to streamline part production through 3D printing so its engineering team can focus on development, design, assembly and other services.

Read More