3 Types of 3D Printed Tooling for Injection Molding: AM Radio #16A

3D printed tooling for injection molding, including mold inserts, components and end of arm tooling, were on display at the Plastics Technology Expo.

Share

Even as polymer 3D printing is increasingly being used for production, tooling remains a major application for 3D printing in the plastics industry. Exhibitors at the 2022 Plastics Technology Expo (PTXPO) were showcasing several examples of 3D printed tooling for injection molding. For mold inserts, 3D printing can aid in rapid prototyping, production molds with conformal cooling channels and mold repair. 3D printing can also be used to produce mold components, such as ejector pins with a porous structure that enables gas to escape a mold while containing the material inside. And 3D printed end-of-arm tooling can be lighter than traditionally produced versions with faster turnaround times.

Peter Zelinski and I talked about all this on the latest episode of the AM Radio podcast. For more details on how 3D printing complements injection molding, listen to the episode above or read on for the transcript.

PTXPO 2022

Transcript

Julia Hider

Pete, I want to say just one word. Just one word.

Peter Zelinski

Yes, Miss Hider?

Julia Hider

Are you listening?

Peter Zelinski

Yes, I am.

Julia Hider

Plastics. That’s coming up on this episode of AM Radio.

Peter Zelinski

The AM Radio podcast is brought to you by the Additive Manufacturing Conference at IMTS, the leading industry event focused on 3D printing for production. We’re currently open to speaker submissions for the 2022 event. Learn more and submit your proposal at AdditiveConference.com.

Julia Hider

Welcome to AM Radio. I’m Julia Hider. And I’m here with Pete Zelinski.

Peter Zelinski

Hey, Julia.

Julia Hider

Hey, Pete. So, I just got back from PTXPO. That’s why we did our little Graduate intro. PTXPO is a trade show that’s put on by our parent company, Gardner Business Media, and it’s a plastics processing show. So, it’s not an additive-focused show, but there is an additive presence. So, we’re going to talk about plastics today.

Peter Zelinski

So, that’s great. I want to hear about PTXPO, Plastics Technology Expo. New show that our employer has begun, Gardner Business Media. Plastics has been on my mind too. There are some pretty fundamental advances happening in plastics 3D printed I’ve gotten interested in I want to talk about. So PTXPO, what was it like?

Julia Hider

Yeah, so like you said, this is the first time the show has ever been held. So, I don't have a direct comparison. But compared to other events that we’ve been to since the pandemic started, this one felt the most like a pre-COVID event. It felt a little more normal. I was there at the end of the first day, and most of the second day, and foot traffic seemed really good, especially on day two. All of the Tech Talks I went to, the theaters were full, and just the general atmosphere felt really positive.

Peter Zelinski

And so the subject matter of the show is broad — it’s plastics manufacturing. It’s not by any means exclusively about 3D printing. And 3D printing was just kind of like a small element of it. But additive had a presence there. What did you encounter that kind of struck you as far as 3D printing taking its place in plastics production?

Julia Hider

Yeah, so for plastics production, I visited the RE3DTECH booth. They’re a 3D printing service provider. And they use a whole bunch of different processes, including HP Multi Jet Fusion, and they’re starting to see production applications for plastic AM using MJF. And they showed me this, like, perfect part that was the perfect example of AM moving into production with plastics. It was a part that was formerly machined from aluminum. And they’re now making it from PA12. And they’re doing more of a manufacturing on demand type model, and ultimately saving the customer a bunch of money. And it was just sort of the perfect example of that.

Peter Zelinski

And you told me a little bit about it. And it’s a part where, like, they showed it to you, but you couldn’t photograph it because there’s still some confidentiality around their customer. But like, like, what, what industry did it have to do with?

Julia Hider

It was a medical part.

Peter Zelinski

And it’s a case of plastics, replacing metal. And we talk about that from time to time. Sometimes things are made of metal, not because you need the metal, but just because machining something out of aluminum is the quickest way to get it. And yeah, now 3D printing in some cases is an even quicker way.

Julia Hider

Yeah, yeah. That was just one example of, you know, plastic production, but most of what I saw was related to tooling.

Peter Zelinski

Okay. Let's talk about that. What kinds of tooling?

Julia Hider

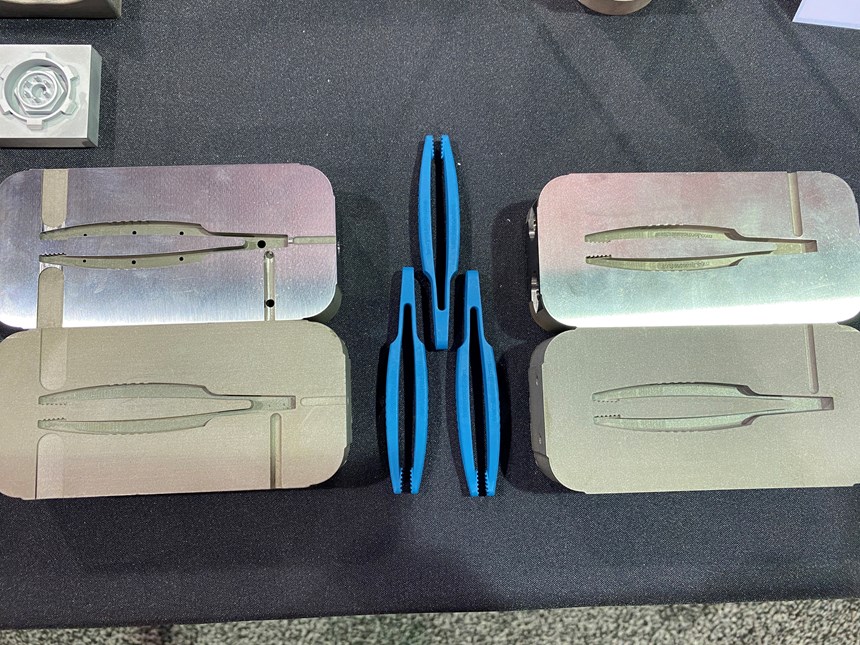

Yeah, so the first big example, this is sort of the bulk of what I saw, was 3D printed injection molded tooling. And I have several sub-examples of this. The first one is Mantle. We’ve covered them before, but they make a system that’s specifically designed for 3D printed mold tooling that uses a flowable metal paste and a hybrid machine tool. They were at the show presenting a case study with another exhibitor, Westminster Tool, which is a mold shop in Connecticut. And they were talking about a project they worked on together, making a mold for a pair of medical tweezers, and Westminster was designing the mold for this part. And it needed to be made out of this 65% glass filled polyamide which is tough to work with. It’s abrasive, it doesn’t flow well and it has narrow molding parameters. So they designed a mold with a conformal cooling channel that would help them mold this material. They designed the mold, and Mantle printed it, sent over the inserts to Westminster where they did a little bit of postprocessing and then they were able to run thousands of these parts. It was more of a prototyping-type application. And they were able to go from design to part in, like, three weeks.

Peter Zelinski

So yeah, the Mantle process, we’ve written about that before. We’ll put a link in the, in the show description to our coverage of this. but it’s, like, a 3D printing with this, like, mud-type material that partially solidifies, can then be machined right in the same process as 3D printed and then it's baked to a harder state later and becomes production ready mold tooling. It’s a) a type of 3D printing process that is different from everything else out there and b) this alternative to get full scale, full production quantity, mold tooling. And now here, Westminster, they’re a mold shop, their business is machining molds. And they’re, they’re evaluating this other way of making mold tooling, has some new freedoms, like you say, the ease of putting conformal cooling in there. I wonder in your conversation with them any, like. little nuances that have come out either positive or challenges about like what they’re discovering about this process?

Julia Hider

Yeah, so we’ve covered this before, but they have done some testing on the material itself. And they’re finding that they can integrate the, you know, Mantle material into their already existing mold, machining processes really easily.

Peter Zelinski

So you said you saw a lot of tooling for plastics and even saw a lot of injection molded tooling. So like, let’s keep going. What’s another example?

Julia Hider

Yeah, so I also talked to Xact Metal, and they have a DMLS system. And one of the really interesting applications that they talked about was their VP of commercial operations, Dave Jankowski, gave a Tech Talk. And he mentioned a case where a customer used the metal 3D printer to repair a mold. So they cut off the damaged part, fixed it in the machine and added new material directly onto the cut surface. And I just thought that was a really interesting application that I hadn’t heard of before.

Peter Zelinski

So Xact Metal, we like them. Laser powder bed fusion machine, and they make these really little machines that are pretty cost effective, in part because the size is so small. But a lot of the metal parts you want to 3D print precise components, they fit within a smaller build envelope and, but laser powder bed fusion, like we always think about starting with a build plate, starting with a flat surface, you’re describing starting with an existing tool and building on top of that. I guess, like, the most basic question that comes to my mind is, do the metal properties come out the same as the. the mold tool you're starting with?

Julia Hider

Yeah, he said that the customer tested the material out and the properties matched. So yeah, it worked out for them.

Peter Zelinski

All right, let’s keep going. More molds, give me more molds.

Julia Hider

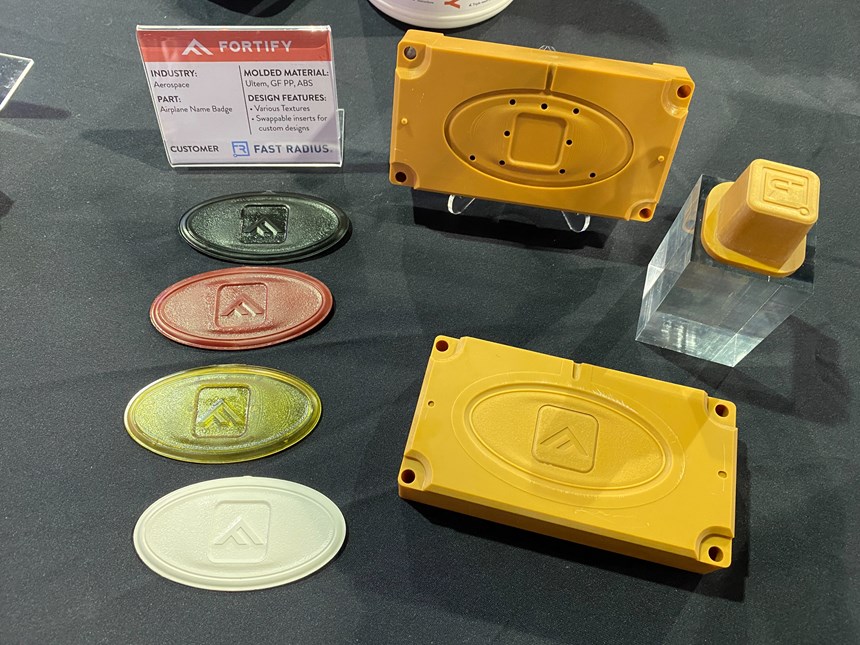

I have one more example for you. This one was at the Fortify booth. And they have a DLP system and a resin that’s reinforced with ceramic fibers for added toughness. It’s really good for making rapid prototype molds. Because you can have a mold that’s ready to use it in three days, and you can get a couple hundred shots out of it.

Peter Zelinski

So, a composite mold tool. That’s interesting. We’ve been talking about 3D printed metal tooling. You see also in some of the more temperature-resistant polymers, sometimes there’s short run bridge mold tooling that are 3D printed that way. This kind of sounds like something in between. So the ceramic reinforcement, ceramic, we tend to think of that as heat resistant material toughness to stand up to the pressures of the molding process. Like, where does this land in terms of the quantities? Did they give you any sense of the shots you can get out of, out of a composite mold tool before it wears out?

Julia Hider

Yeah, so it depends on a lot of factors, like you know, the how detailed the design of the mold is, and how tough the material that they’re molding is, but they said it can be anywhere from 25 to a 1,000 shots with 25 to 200 as sort of being their sweet spot.

Peter Zelinski

So that’s just molds, but you kind of, like, give the sense you saw plastics tooling beyond just the molds.

Julia Hider

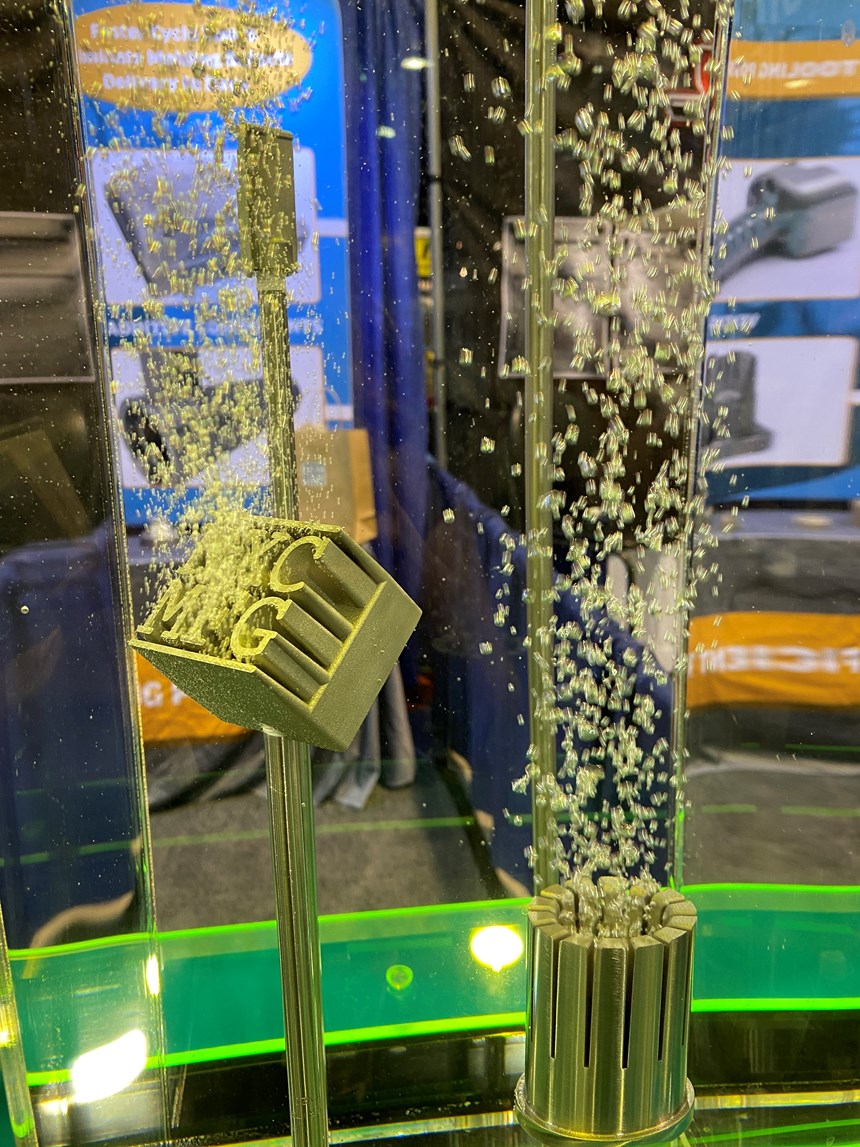

So yeah, another example of 3D printed tooling that I saw that wasn’t injection molded tooling is 3D printed molded components. So, Next Chapter Manufacturing was at the show, and they were showcasing these 3D printed ejector pins. They also do 3D printed injection molded tooling, but they started making these ejector pins that can vent gases out of a mold, and they call them Innovent pins. Get it?

Peter Zelinski

I get it. Oh, that is so inventive.

Julia Hider

But yeah, they’re made out of steel using DMLS. And they kind of have what they described as a porous structure on the inside that can let gases out without letting any of the material out. And they had this cool demo at their booth with some 3D printed parts that they were submerged in a tank of water and then they had air going up through the parts and you can see the air bubbles coming up through the water to show the porosity.

Peter Zelinski

Okay, controlled porosity. I love that. It’s another one of these design possibilities you can get from 3D printing way, way, way back. When 3D printing was first entering production, like that was one of the raps on it. Sometimes, there was porosity. We’re long past that. We get fully dense parts and we’ve controlled it to such an extent that there are some kinds of parts where you want to build in the porosity for the the useful effect you get out of it. Did an episode of The Cool Parts Show about these air filters that were made with controlled porosity. That was an idea, a prototype, but now here, it seems like these Innovent pins, real production components made with controlled porosity built in. Did you learn more about that? Like, like, how did they get exactly the porosity they want? How did they achieve that?

Julia Hider

Yeah, he said it was, it’s like a physical thing. It’s not a chemical thing. And they said it was sort of a combination of design and manipulation of process parameters.

Peter Zelinski

Yeah. So it’s just, like, control of the positioning of the laser as it’s hard to get hardening the material to leave some microscopic channels through the part. I guess, here’s what this reminds me of kind of — ejector pins. You have written about additive manufacturing, making cutting tools for machining, like cutting tools, basic fundamental component of CNC machining, so ejector pin basic fundamental component of molding, so here’s, like, additive serving conventional processes.

Julia Hider

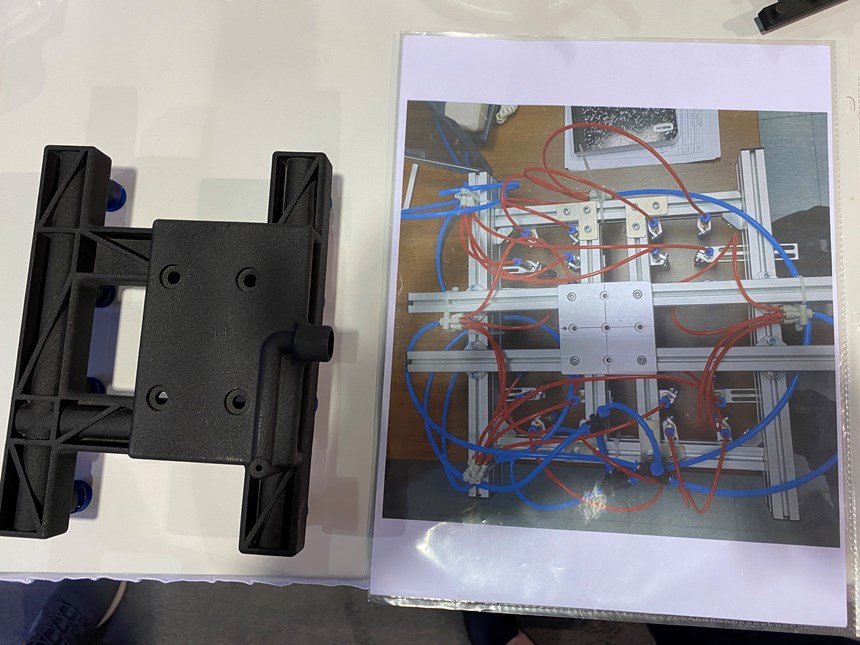

Exactly. And I have one more tooling example to talk about from the show. Alright, 3D printed end-of-arm tooling for automating injection molding, I talked to Savage Automation. And all they do is 3D printed end-of-arm tooling. They showed me an example of what this typical end-of-arm tooling looks like. And it’s usually made out of metal, and it has all these tubes coming out for the vacuum gripping mechanism. So, this company designs end-of-arm tooling that has internal channels for the airlines instead of needing the hoses and tubes. And they can make it faster than traditional end-of-arm tooling. And it’s also lighter than metal, which means that the robot can move faster and there’s less wear on it.

Peter Zelinski

Okay, 3D printed end-of-arm tooling. So, Savage Automation. Like is that their whole gig — people come to them for 3D printed solutions and end-of-arm tooling?

Julia Hider

Yeah, that’s all they do. They don’t even do the printing for the production parts in house. They have a Markforged machine that they use for prototyping, but they ultimately send their work out to a service bureau for printing. And so they can just focus on the design of the part.

Peter Zelinski

Okay, so they’re prototyping them on a Markforged, they send them out. So what 3D printing process makes the final production tooling?

Julia Hider

Yep, that’s also HP Multi Jet Fusion.

Peter Zelinski

So can we see examples anywhere?

Julia Hider

Yeah, so I have pictures and videos of, I think, everything that I talked about on Twitter and Instagram. We can post links to them in the show notes as well.

Peter Zelinski

Okay, so um, you saw a lot of tooling at PTXPO molds, molded components, end-of-arm tooling. Like, I think that is just about all the tooling that goes into injection molding, pretty comprehensive.

Julia Hider

Yeah. So I think that’s a good place to wrap up this part of the conversation. And when we come back from the break, we will talk some more about polymer additive manufacturing.

Peter Zelinski

Yeah, I want to do that.

Related Content

-

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

-

BMW Expands Use of Additive Manufacturing to Foster Production Innovations

The BMW Group is manufacturing many work aids and tools for its own production system using various 3D printing processes, with items such as tailor-made orthoses for employees, teaching and production aids, and large, weight-optimized robot grippers, which are used for such things as carbon fiber-reinforced polymer roofs and entire floor assemblies.

-

8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples.

Related Content

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

Read MoreBMW Expands Use of Additive Manufacturing to Foster Production Innovations

The BMW Group is manufacturing many work aids and tools for its own production system using various 3D printing processes, with items such as tailor-made orthoses for employees, teaching and production aids, and large, weight-optimized robot grippers, which are used for such things as carbon fiber-reinforced polymer roofs and entire floor assemblies.

Read More8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples.

Read MoreFoundry Lab: How Casting in a Day Will Improve the Design of Metal Parts (Includes Video)

The company’s digital casting process uses 3D printing, but the result is a cast part. By providing a casting faster than a foundry, the company says effective prototyping is now possible for cast parts, as well as bridge production.

Read MoreRead Next

Alquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More