Prototyping

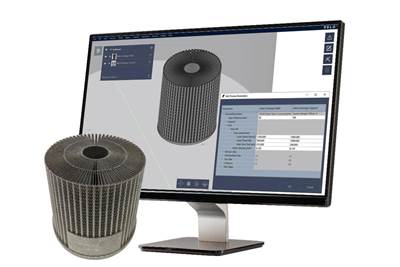

Velo3D’s Flow Developer Enhancement Simplifies Parameter Development Process

The Developer enhancement in Velo3D’s Flow print preparation software gives users the freedom to migrate their own 3D printing parameters, even if developed on other brand machines, to a Velo3D Sapphire system where they can take advantage of machine-to-machine repeatability for series production.

Read MoreVideo: Ergonomics and Economics of Really Big Laser Powder Bed Fusion

The DMP Factory 500 solution currently operating at CIMP-3D offers a look at the equipment and steps necessary to 3D print metal parts at large scale.

WatchThe Softer Side of Robots: Automating Additive Manufacturing

Robotic applications are expanding in additive manufacturing thanks to rubber and silicone-based systems that can easily adapt to parts of varying sizes and shapes without reprogramming.

Read MoreNikon Lasermeister Metal DED 3D Printer and Scanner Developed for Industrial Applications, Turbine Blade Repair

This technology gives manufacturers the ability to build onto existing parts with high precision and utilize a variety of materials, reducing lead times and minimizing postprocessing requirements.

Read MoreRoss V Cone Blenders Provide Gentle, Effective Mixing

The Ross V Cone Blender is a common workhorse used throughout the process industries for mixing powders and other free-flowing solids.

Read MoreSintavia Plans $25 Million Expansion in Hollywood, Florida

The investments in facilities and equipment will power company’s growth over the coming years, including being able able to meet the demand from the programs it supports for the U.S. Department of Defense.

Read MoreUltiMaker Targets Light Industrial Applications With 3D Printer Designed for the Factory Floor

The company’s Factor 4 3D printer introduced this week is designed to complement conventional manufacturing equipment including CNC machining and automation.

Read MoreQ.ANT’s Compact Quantum Sensor Analyzes Particles for Improved Quality Control in Additive Manufacturing

The particle sensor measures the size, speed and trajectory of particles in liquids and gases.

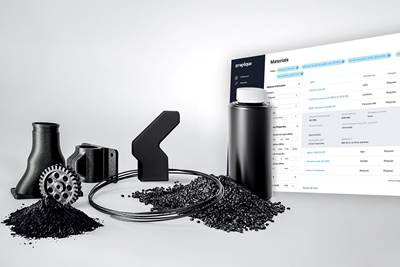

Read MoreReplique Announces Public Launch of 3D Printing Material Hub

Following a successful beta release, the Material Hub is now openly accessible to the broader additive manufacturing community. It contains a collection of more than 400 polymer materials which have been compiled in collaboration with more than 25 material providers.

Read MoreHow Machining Makes AM Successful for Innovative 3D Manufacturing

Connections between metal 3D printing and CNC machining serve the Indiana manufacturer in many ways. One connection is customer conversations that resemble a machining job shop. Here is a look at a small company that has advanced quickly to become a thriving additive manufacturing part producer.

Read More