Nikon Lasermeister Metal DED 3D Printer and Scanner Developed for Industrial Applications, Turbine Blade Repair

This technology gives manufacturers the ability to build onto existing parts with high precision and utilize a variety of materials, reducing lead times and minimizing postprocessing requirements.

Share

Read Next

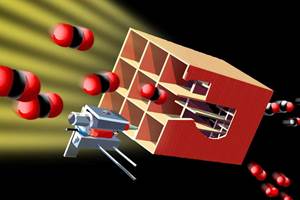

Nikon Corp.’s latest metal additive manufacturing (AM) system includes the Lasermeister LM300A which uses directed energy deposition (DED) technology, as well as the complementary 3D scanner, Lasermeister SB100. While the system’s predecessor, the Lasermeister 100A metal AM system series, is well suited for research purposes, the company says this latest solution was specially developed for industrial applications.

Building upon the processing capabilities of the previous systems, the LM300A supports an expanded build area and is also equipped with the newly developed 3D scanner, the SB100. This 3D scanner supports factory automation by enabling users to scan each workpiece with the click of a button and then automatically generates the toolpath data for the 3D printing process to begin.

The company says the pairing of the LM300A and SB100 delivers tremendous value to the industry, particularly for applications such as repairing turbine blades and molds.

Currently, turbine blades are used in aircraft engines and power generators to help extract energy from hot gas. However, due to exposure to harsh conditions, turbine blades can degrade over time and periodically the worn-out blades must be repaired to continue usage. The traditional turbine blade repair process involves cutting and scraping the worn area for each blade, which takes time and generates waste. The blade is then manually welded for repair and grinding is performed to restore the part to its ideal shape. This repair process introduces many challenges, such as difficulties in securing highly skilled welders, which can lead to quality consistency issues and long lead times.

To address the challenges in the conventional repair process, Nikon developed the LM300A and SB100 as a solution that can reduce lead times up to 65% compared to the conventional welding process and minimize postprocessing requirements. In addition to the turbine blade example, this technology can provide great value to automobile, railway, machinery industry and other repair applications.

The system offers seamless scanning and toolpath generation. By placing a workpiece, such as a worn-out blade, inside the SB100, with a click of a button, the module begins to scan and measure the workpiece inside the chamber. It then compares its current actual shape with the CAD model to extract the difference, using a built-in, high-precision scanning feature. The SB100 then automatically generates the toolpath data for repair specific to each damaged or worn-out workpiece.

This entire process is easily completed and does not require any special skills or manual cutting of the repair area. The toolpath data is then transferred to the LM300A to initiate high-precision additive manufacturing. Once the additive process is completed, the workpiece can be placed back into the SB100, where it will scan and inspect to confirm the repair was performed to match the model. This automation and streamlined workflow can lead to reduced costs and lead time for industrial users.

The system also offers high-precision processing for various metal materials. The LM300A performs high-precision processing by leveraging advanced optical and precision control technology developed across decades of Nikon semiconductor lithography systems. In the case of turbine blade repair, the LM300A can process within the accuracy of ±0 mm to a maximum ±0.5 mm difference for the XY-axis direction and ±0.5 mm to maximum ±1.5 mm difference for the Z-axis direction, achieving ultrahigh precision. In addition, real-time laser power control by the meltpool feedback system delivers smooth surface finishing and precise processing of parts, ultimately achieving crackless repair with optimal quality and stability.

The ability to build onto existing parts with high precision and providing an advanced repair solution which is compatible with a variety of materials are key benefits of this Nikon AM technology.

LM300A supports metal materials such as Nickel based alloy (Ni625, Ni718), Stainless Steel (SUS316L), High Speed Steel (SKH51/M2/HS6-5-2) and Titanium alloy (Ti64/Ti-6Al-4V), and it is an open system, depending on customer requirements.

Related Content

3D Printed Spacer Grids for Nuclear Power: The Cool Parts Show #79

Westinghouse Electric Company is exploring laser powder bed fusion as a means of manufacturing spacer grids, critical parts of the fuel rod assemblies used in pressurized water reactors.

Read MoreResearchers Use Additive Manufacturing to Make Aircraft Propulsion Systems More Eco-Friendly

Project researchers aim to utilize hydrogen fuel cells and additive manufacturing as a pathway to achieve low-emission aviation by 2050. The goal is to recuperate the waste heat of a fuel cell-electric propulsion system, paving the way for a clearer, more sustainable future in aviation.

Read More3D Printed Reactor Core Makes Solar Fuel Production More Efficient

The solar reactor uses water and CO2 from the air and sunlight as the energy source to produce carbon-neutral liquid fuels, for example, solar kerosene for aviation.

Read MoreHeat Exchangers 3D Printed from Haynes Alloy: The Cool Parts Show Bonus

Heat exchangers used in concentrated solar power must withstand elevated temperatures and pressures, and 3D printing enables the use of materials appropriate to this application.

Read MoreRead Next

Bike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More