Prototyping

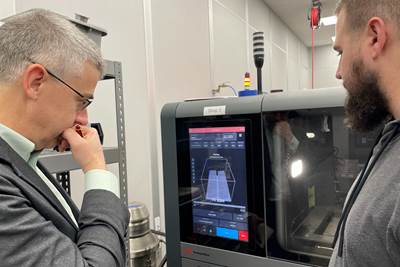

Formlabs’ Form 4 3D Printer Offers New Levels of Reliability and Speed for Stereolithography

The Form 4 is designed to deliver most parts in less than two hours, offering users a powerful, affordable tool to bring ideas to life at fast speeds with excellent reliability, print quality and ease of use.

Read MoreFreeform: Binder Jetting Does Not Change the Basics of Manufacturing

Rather than adapting production methodologies to additive manufacturing, this Pennsylvania contract manufacturer adapts AM to production methodologies. In general, this starts with conversation.

Read MoreVideo: Binder Jetting Production Workflow at Freeform Technologies

Additive manufacturing via binder jetting includes a sequence of downstream steps. During a visit to the Pennsylvania metal 3D printing part producer, I had the chance to walk through this process.

WatchAccufacture Develops Alchemist 1 Robotic AM Cell Engineered With Meltio’s Wire-Laser Metal 3D printing Technology

This all-in-one additive manufacturing robotic work cell was engineered for seamless integration and rapid deployment for the safe and reliable manufacture and repair of metal parts.

Read MoreFormnext 2024 Announces Call for Speakers

The proposals for papers can be submitted no later than June 30, 2024.

Read MoreSpring 2024 TRX Showcases Projects Designed to Drive Additive Manufacturing Advancement

The America Makes TRX platform promotes exploration with more than 30 highlighted projects that are designed to propel the additive manufacturing industry.

Read More3D Printed Tennis Racket Serves a Collaborative Win

The collaboration between All Design Lab and Protolabs led to the creation of a 3D printed tennis racket via direct metal laser sintering, called Hìtëkw. This project not only pushed the limits of additive in terms of design capabilities but revealed how important active communication between customer and manufacturer can be for a project’s success.

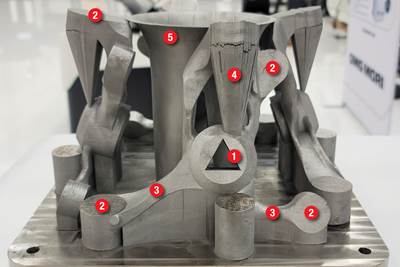

Read MoreDesigning a 3D Printed Part with Machining in Mind

Designing extra stock and mounting features into a 3D printed part can aid in machining processes downstream.

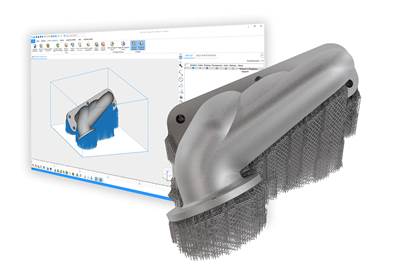

Read MoreMaterialise and Renishaw Integrate Systems to Improve Efficiency of Metal 3D Printing

Renishaw system users can now benefit from Materialise’s build processor software as well as its Magics data and build preparation software.

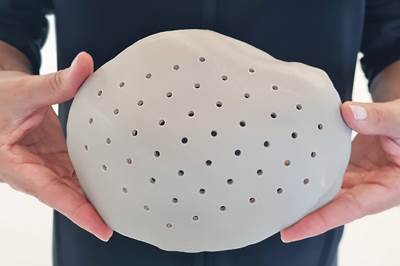

Read More3D Systems Receives FDA Clearance for World’s First 3D Printed PEEK Cranial Implants

The FDA clearance now enables widespread adoption of 3D Systems’ self-contained, cleanroom environment-based printing system, the EXT 220 MED, with medical-grade PEEK materials to deliver patient-specific cranial reconstruction solutions.

Read More