Prototyping

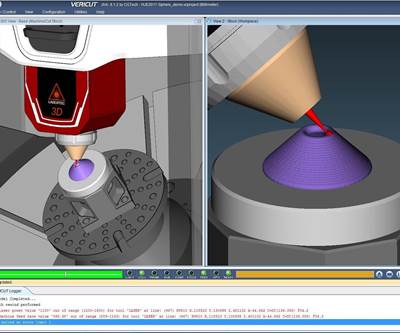

Webinar Highlights Simulation for Hybrid Manufacturing

A May 15 webinar hosted by CGTech tackles verifying NC code for hybrid machine tools.

Read MoreRenishaw Launches Additive Manufacturing Guide

The online resource is intended to help increase the use of AM in mainstream manufacturing.

Read MoreHybrid Production, Not Just Prototyping, at Matsuura's New Additive Manufacturing Center

The new Matsuura Machinery USA Lumex Additive Manufacturing Center is one part lab, one part showroom and one part production facility—all meant to showcase the company’s hybrid manufacturing capabilities.

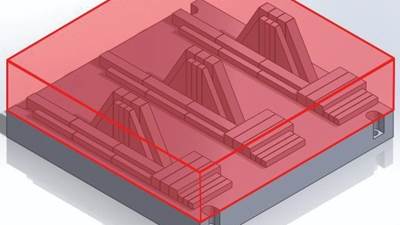

WatchSimufact Additive 3 Software Provides Thermal Mapping

Simufact Additive 3 uses thermal mapping to identify areas of problematic heat buildup at an early stage in the metal 3D printing process.

Read MoreWhy Does My 3D-Printed Part Cost So Much?

The machine, the facility and the material are just three costs behind the price tag.

Read MoreWebinar Explores Cobots for Additive Manufacturing

A free May 9 webinar hosted by Universal Robots addresses the use of collaborative robots (cobots) alongside 3D printing.

Read MoreCustom Tooling Unmasks Process Costs in Metal Coating

The tooling that had long been accepted was contributing to unnecessary manual labor for this PVD coater. Now, the company has improved its process with custom tools that are 3D-printed in production quantities.

Read MoreRize Supports Digitally Augmented Parts (DAP)

Voxel-level ink jetting via Rize's Augmented Polymer Deposition process enables the embedding of QR codes and other identifying information.

Read MoreGM Seat Bracket Made with Autodesk Generative Design Software

The bracket is the result of a multi-year alliance between the two companies to explore generative design, AM and materials science for vehicle lightweighting.

Read MoreAdditive Manufacturing at NPE2018, from Prototyping to Production

Attending NPE2018 next week? Here's what to expect from an additive manufacturing perspective, including a new zone and workshop focused on 3D printing.

Read More