Rize Supports Digitally Augmented Parts (DAP)

Voxel-level ink jetting via Rize's Augmented Polymer Deposition process enables the embedding of QR codes and other identifying information.

Rize has announced the ability for its 3D printing technology to create Digitally Augmented Parts (DAP), functional parts aumgented with digital information. With this capability, the company says that users can create a digital thread between the digital and phyiscal part to make use of Industry 4.0 technologies such as blockchain and augmented/virtual reality applications.

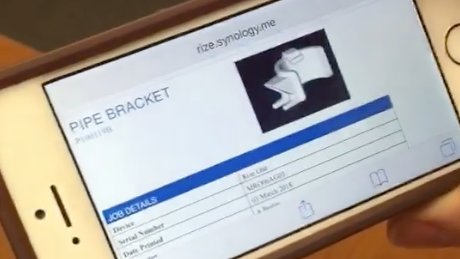

With Rize’s Augmented Polymer Deposition (APD) 3D printing process, which combines extrusion and material jetting, users are able to 3D print industrial parts with embedded markers to counter noncompliance due to design changes, piracy, counterfeiting and obsolescence. APD’s voxel-level ink jetting capability enables the printing of secure information on industrial parts, such as QR codes which can be scanned with a smartphone to access corresponding information online.

This capability also enhances the usage of the new 3MF format for 3D printing which carries intelligence on the additive part, the company says.

“This is the first step towards embedding intelligent capabilities within the part and connecting them through a digital thread into the digital twin of the part,” says Andy Kalambi, president and CEO of Rize Inc.

Related Content

-

What Does Additive Manufacturing Readiness Look Like?

The promise of distributed manufacturing is alluring, but to get there AM first needs to master scale production. GKN Additive’s Michigan facility illustrates what the journey might look like.

-

3D Printed Lattices Replace Foam for Customized Helmet Padding: The Cool Parts Show #62

“Digital materials” resulting from engineered flexible polymer structures made through additive manufacturing are tunable to the application and can be tailored to the head of the wearer.

-

6 Trends in Additive Manufacturing Technology at IMTS 2024

3D printers are getting bigger, faster and smarter. But don’t overlook the other equipment that the AM workflow requires, nor the value of finding the right supplier.