Additive manufacturing can reduce the role any of a number of operations that might be part of a manufacturing process today. For example, adopting AM might reduce the need for machining or, by enabling part consolidation, it might reduce assembly. At PMT Shielding Solutions in Tigard, Oregon, 3D printing accomplished both these things. Yet perhaps the most significant impact it has had relates to manual labor. With 3D printing now used to produce tooling, the labor required for each job here is less, and the pace of this company’s process is now less affected by manual effort than it once was.

PMT specializes in coating plastic parts with metals, often aluminum and copper, to provide shielding against electromagnetic or radio interference. Aerospace, defense and medical are all important industries, because all these sectors employ sensitive devices that cannot be allowed to fail because of a stray external signal. A medical device’s plastic housing receiving metal shielding on its inside surfaces is a type of part that is typical. The company has a physical vapor deposition (PVD) process involving metal vapor applied within a vacuum that adds a 1-micron-thick metal coating to all part surfaces not blocked by masking. Yet because some surfaces of almost any part must be kept free of the coating for the sake of assembly, applying or attaching masking to every piece is generally a major labor component of PMT’s work. As business has surged, employees have felt pushed to keep up.

But company leaders recently found a way to relieve that pressure, moving to 3D printing to create custom tools for the coated parts in place of masking using silicon or metal shields. The company bought first one “3ntr” brand polymer 3D printer from Plural Additive Manufacturing, then a second of these machines several months later, both for the mass production of fixtures for masking.

Now, the labor content of PVD coating is less. And in some cases, it is substantially less, because the availability of in-house 3D printing has allowed PMT’s staff to iteratively develop one-piece custom tools for parts that in the past required many separate touches to mask completely. The freedom to innovate and iterate is one of the most important benefits of having additive manufacturing capability in-house rather than relying on an external service bureau, according to PMT General Manager Adam Anaforian.

And he notes that the production rate now, in addition to being faster, is also more predictable. Reliance on manual effort to ensure proper masking of each piece using a collection or assembly of masking components has traditionally meant that productivity differed from person to person and from day to day. Even the rate through the quality assurance process could vary, because where 3D printing allows for detailed masks that fit the part perfectly, previously the company used simple masking solutions that were comparatively crude. Masking parts in the absence of custom fit means finesse has to be applied to ensure the simpler masks work, and finesse can sometimes fail. PMT Quality Inspector Athena Reynolds describes the effect the move to 3D printing has had in the case of one representative part, an infusion pump housing component. Improved masking of this part translates into reduced need for her to clean misplaced coating from individual pieces in order to complete them. As a result, the number of housings she can inspect in an eight-hour shift has gone from 400 to 500 up to 1,000 to 1,200. In short, AM wins productivity improvements both prior to the coating operation and after it as well.

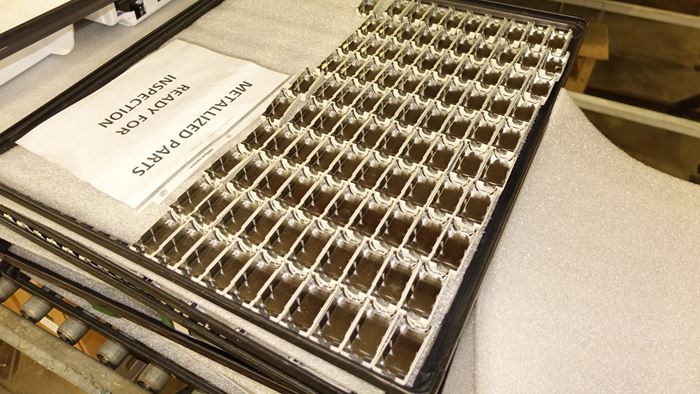

Production Quantities

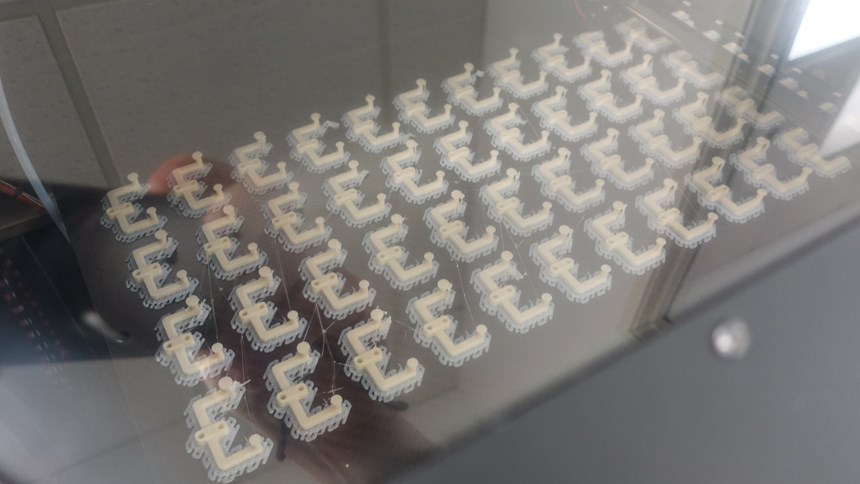

PMT’s masking tools are most strikingly different from other types of tooling in the area of quantity. A more typical tool—think jigs, fixtures or molds—can be used again and again for piece after piece. The same mold might make a million units. But PMT's coating operation is a batch process in which racks of plastic pieces are loaded into a vacuum chamber together. Every individual piece needs its own masking. As a result, PMT's creation of tooling is essentially a production operation. The two 3D printers run around the clock and through the weekends to generate hundreds of identical tooling components with each build.

“It seems strange to think about now, but previously, we doubted we could justify our own 3D printing,” Anaforian says. In any process, inefficiencies and shortcomings tend to be invisible because they are familiar. Keeping surfaces masked from coating in the past has involved, in various cases, silicon pads or plugs cut or molded to size; hard tooling built from machined components made by a nearby machine shop; and occasionally 3D-printed parts from a service bureau. The machine shop and the service bureau both represented options for creating custom tooling, and in theory these options seemed sufficient.In practice, however, the limitation the coater had come to accept was a generally imperfect fit resulting from a series of simple custom components being assembled together. The cost and distance of an external service provider limited how daring PMT was willing to be in devising elaborate tools that might fit detail for detail without any assembly required. Only a chance encounter with Plural Additive Manufacturing (related to a customer part that was 3D-printed) led PMT to question this acceptance. The team members here realized that both the cost and the learning investment for 3D printing might not be as high as they had assumed. Anaforian says just the cost difference between in-house and outsourced tooling proved sufficient for the first printer to pay for itself in seven months.

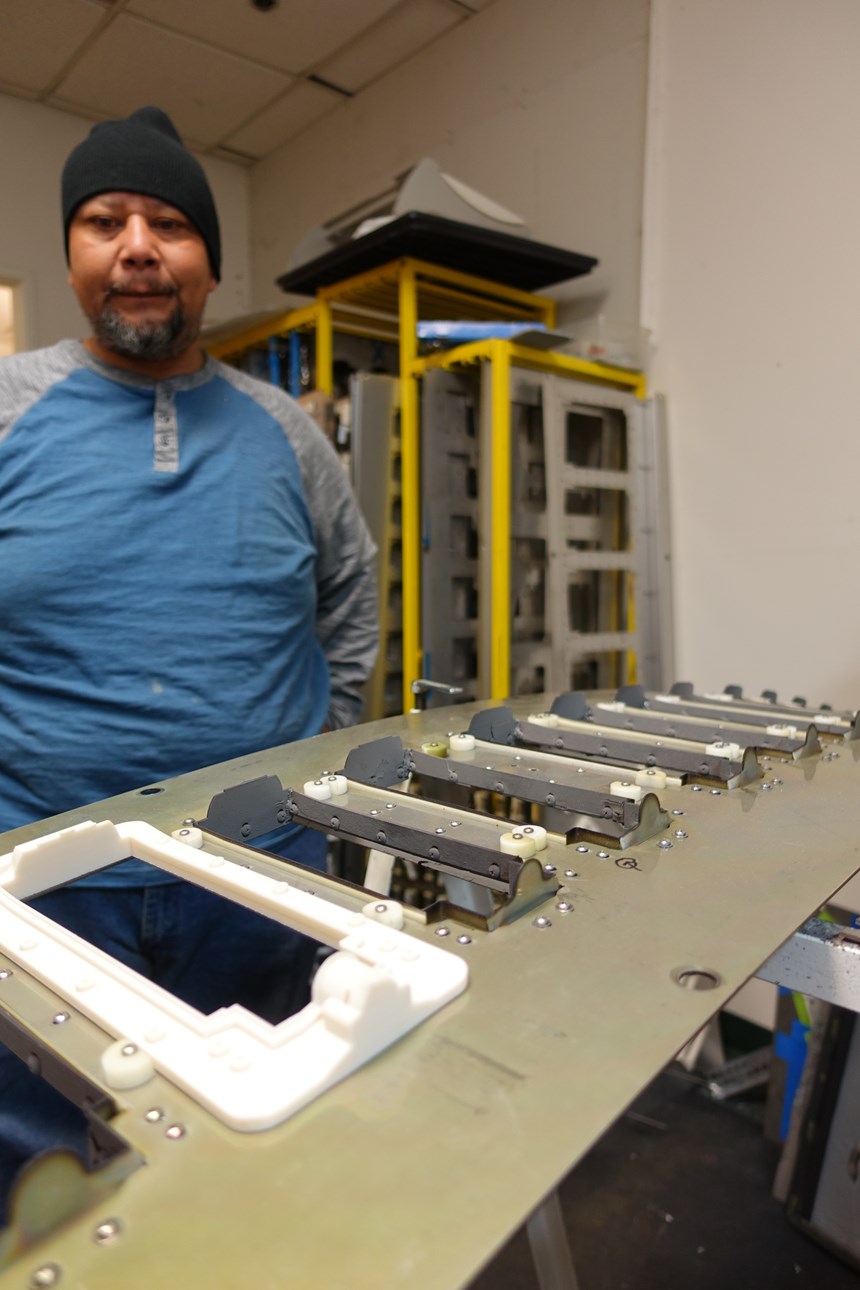

And during these early months, he and others in the company grew accustomed to their slightly changed roles, he says. Senior Mechanical Engineer Jason Hennessy, who works remotely for the Oregon company from an office in Minnesota, now designs elaborate 3D-printed tools based on customer part data. Anaforian maintains the 3D printers and keeps them loaded with material—a new responsibility that is not all that difficult or even inconvenient, given that the machines run in a room near his office. And the one whose job has perhaps most significantly changed for the better is Process Engineer Victor Figueroa, who is now much less of a repairman and troubleshooter for old tooling, and instead gets to be more of an inventor.

A Custom Tool Saves Effort

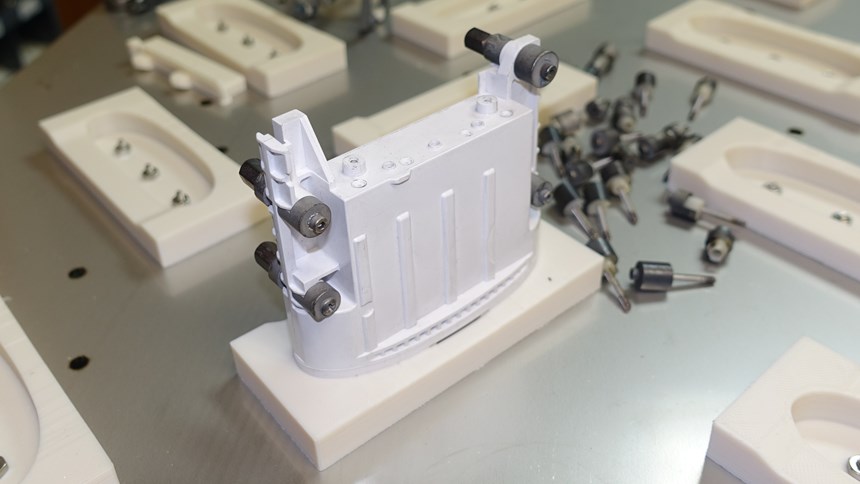

In his workroom, Figueroa showed me some of the tooling he has long maintained and repaired, and how 3D printing is making all this work easier. A 3D-printed mask that fits like a custom lid over a geometrically complex medical device housing replaced an assembly of machined components that previously allowed coating to sometimes slip through the seams. But far more difficult still was the rack of tooling for a frequently recurring small part, a component of a medical pump. Sheet metal guards were employed to mask each identical piece at each of the pockets where these parts mounted, but Figueroa says there were several problems with this tooling.

“To get the part mounted just right, so the sheet metal covered just the right portion of the part, the operator needed calipers,” he says. Setup time was therefore long. And over time, the sheet metal pieces got bent. “I'd fix them, but it was never perfect.” As a result, the masking differed from piece to piece. Plus, there was a potential quality problem: “The sheet metal could scratch the metal coating,” he says.

3D printing will fix every one of these problems. The hard tooling using sheet metal is still in use for now, but as capacity permits on the 3D printers, this tooling will be replaced using masks that are designed to precisely match and mate with the part. In the new tooling solution, every mask will be identical, made from rugged polymer that will resist abuse. Setup will be simple, and the plastic masks will offer no threat if they happen to rub against parts that have just been coated.

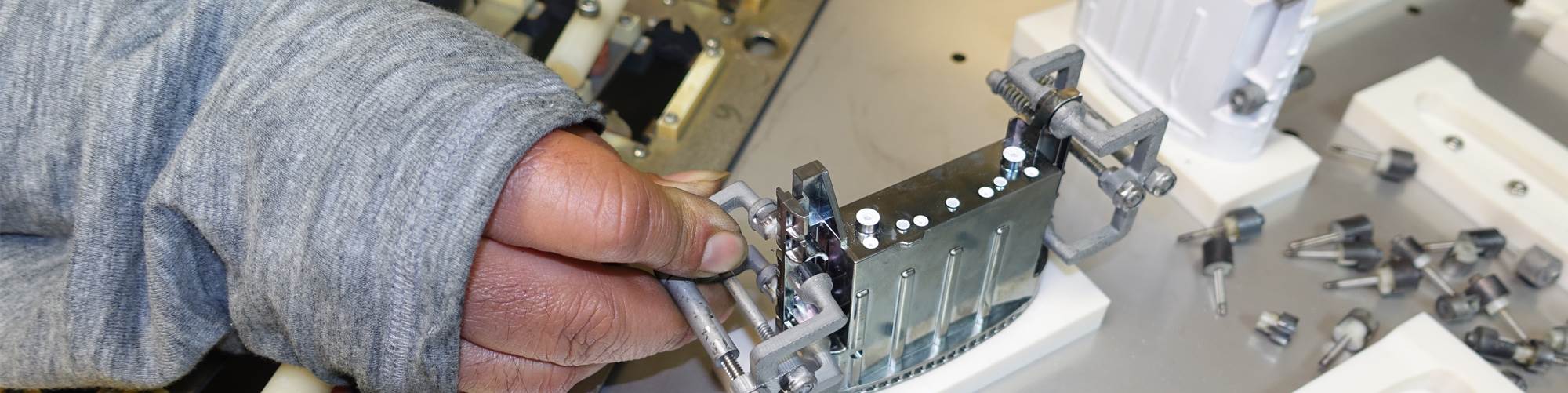

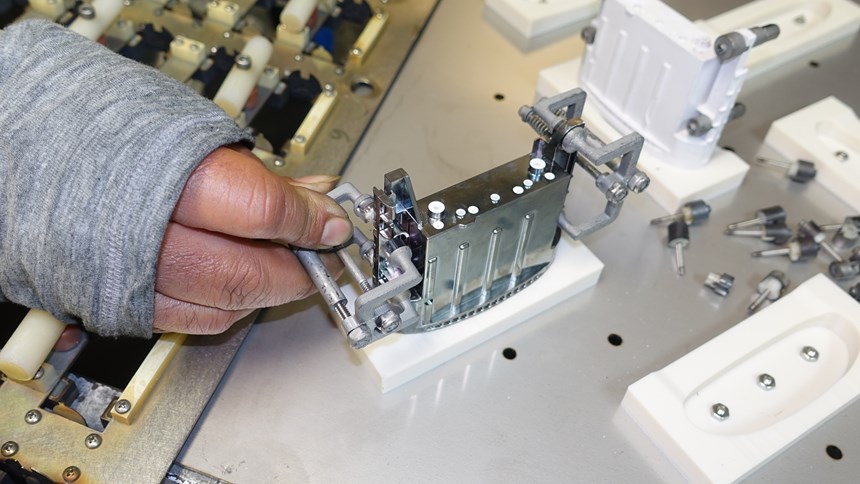

Perhaps the solution to date of which Figueroa is most proud is a spring-loaded tool for keeping the threaded holes free of coating on a medical-device electronics housing component. In the past, covering and protecting the attachment holes for this part meant manually screwing a plug into each one. Running a batch of these parts would mean screwing and unscrewing so many plugs that the employee’s hand would fatigue. The new solution Figueroa helped to devise (it was actually a team effort that went through four iterations before the team got the design right) takes the form of a custom clamp that covers four of this part's threaded holes with a simple squeeze of the tool. Two such custom tools mask each piece completely, replacing in just two clampings the masking that used to involve eight screwed and unscrewed plugs. As exemplified by this invention, PMT has now begun to explore possibilities in efficient masking that it would have never seen a practical way to realize prior to in-house 3D printing.

Take a Cue from the Queue

Business is still growing for PMT: An increasing reliance on sensitive electronics and increased concern about their fidelity creates more of the sorts of opportunities the company was founded to address. And for much of the past year, in-house 3D printing has been crucial for keeping up.

Indeed, the capability is already accepted and assumed. On the day I visited, a clustering of orders—various jobs from various sources that happened to come at once—had resulted in a backlog on the 3ntr machines. Tooling work queuing for 1,800 hours into the future put a brake on the speed by which jobs could be run and delivered. That tooling backlog is now considerably less, but the predicament made clear how far and how quickly additive manufacturing has advanced in this company. Not long ago, it was the capability PMT wasn’t sure it could justify. Now it has become a crucial factor able to affect the output and delivery of all the rest of the process.

Related Content

8 Cool Parts From Formnext 2024: The Cool Parts Show #78

End-use parts found at Formnext this year address various aspects of additive's advance, notably AM winning on cost against established processes.

Read MoreHow Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

Read MoreBeehive Industries Is Going Big on Small-Scale Engines Made Through Additive Manufacturing

Backed by decades of experience in both aviation and additive, the company is now laser-focused on a single goal: developing, proving and scaling production of engines providing 5,000 lbs of thrust or less.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read MoreRead Next

Postprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More