Polymer

AM Solutions’ Postprocessing Systems for Additively Manufactured Parts

Formnext 2022: AM Solutions offers postprocessing technologies for a full range of AM-produced materials.

Read MoreHow to Build 10,000+ Shot Molds in Hours

Rapid tooling isn’t so rapid when it takes days to 3D print a metal mold, and then you still must machine it to reach the necessary tolerances. With Nexa3D’s polymer process you can print a mold in hours that is prototype or production ready and can last for more than 10,000 shots.

WatchSigma Labs to Operate as Sigma Additive Solutions

This name change reflects strategic initiative to deploy technology on thousands of production printers.

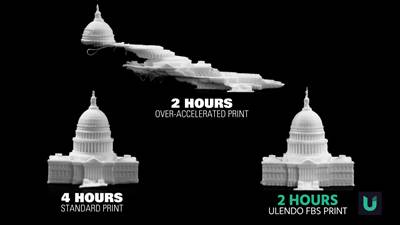

Read MoreSolving 3D Printing’s Hidden Problem: Vibration

Ulendo’s vibration compensation software can double the speed of FFF 3D printers while maintaining part quality, all without changing the machine’s hardware.

Read MoreChromatic’s Smooth-Mode Technology for 3D Printing Durable Rubber Parts

The new technology is well suited for manufacturing rubber bladders and other elastomeric products that expand and contract.

Read MoreIntrepid Automation’s Valkyrie Systems for Industrial-Scale Additive Manufacturing

System features modular DLP technology for a customizable, industrial-scale system for high-volume production.

Read MoreAdditive Manufacturing at IMTS 2022: In the AM Pavilion, and Beyond: AM Radio #26A

Applications and technology for additive manufacturing — not just 3D printing — were widespread across the International Manufacturing Technology Show. Listen to our live discussion recorded during the event for observations on AM at IMTS.

Read MoreRapid Shape Opens North American Headquarters

With local sales, logistics and support activities, the company says it is positioned to better serve the U.S. and Canadian markets.

Read MoreNexa3D Shows Autonomous Automation for Additive Manufacturing

High-throughput selective laser sintering features automated changes of the complete build unit.

Read MoreHow Hybrid Tooling — Part 3D Printed, Part Metal Shell — Accelerates Product Development and Sustainability for PepsiCo

The consumer products giant used to wait weeks and spend thousands on each iteration of a prototype blow mold. Now, new blow molds are available in days and cost just a few hundred dollars.

Read More