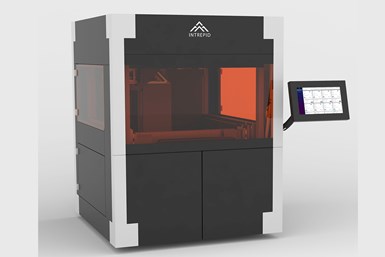

Intrepid Automation’s Valkyrie Systems for Industrial-Scale Additive Manufacturing

System features modular DLP technology for a customizable, industrial-scale system for high-volume production.

The Valkyrie system has customer-validated print speeds of up to 44 mm/hour using IntrepidCast LF resins. Photo Credit: Business Wire

Intrepid Automation’s Valkyrie 3D printing system is a large-format, industrial-grade, modular tool for manufacturing customers to quickly scale production of printed patterns, molds and parts. The system features a build area of 660 × 760 × 560 mm and has customer-validated print speeds of up to 44 mm/hour using IntrepidCast LF resins, which is said to enable users to produce end-use parts up to 10 times faster than legacy SLA processes.

Valkyrie systems run on Intrepid’s moduclar DLP technology, which is a process that uses an array of highly calibrated digital light sources to project a single, high-accuracy image at once, rather than tracing image outlines as it is with legacy SLA processes.

As part of close partnerships with multiple industrial-scale resin suppliers, the company has been able to develop and validate custom materials for applications in both investment casting patterns (IntrepidCast LF resin family) and rigid part/mold production (Intrepid ThermoRigid resin family) on Valkyrie systems.

Automatic calibration and proprietary software are said to ensure print-to-print and printer-to-printer consistency as customers scale manufacturing. The modular system is designed to scale with production needs. The system is also customizable for use with application-specific resins/print materials.

Related Content

-

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

-

Video: Construction 3D Printing with Robotics, Geopolymer

Alquist 3D is aiming to revolutionize construction and infrastructure with large-format robotic 3D printing using a carbon-neutral material.

-

Looking to Secure the Supply Chain for Castings? Don't Overlook 3D Printed Sand Cores and Molds

Concerns about casting lead times and costs have many OEMs looking to 3D print parts directly in metal. But don’t overlook the advantages of 3D printed sand cores and molds applied for conventional metal casting, says Humtown leader.