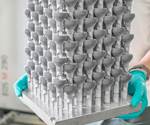

Romain Dumas, founder of the RD Limited multi-discipline racing team, competed in the 2021 Dakar Rally driving a DXX buggy equipped with several components that were designed and additively manufactured by Poly-Shape.

Photo Credit: Poly-Shape

Off-road races, such as the Dakar Rally, are designed to test the limits of vehicles, as well as their mechanics and crews. Vehicles must be reliable and continue performing across difficult landscapes. Additive manufacturing (AM) technology is enabling teams to produce stronger, lighter vehicle components to help meet these demands. For example, in 2017, Romain Dumas, a Porsche factory driver and founder of the RD Limited multi-discipline racing team, won the Pikes Peak International Hill Climb driving a car equipped with a hub carrier that was 3D printed by Poly-Shape, a French subsidiary of AddUp. Since then, their technological partnership has grown — the DXX buggy Dumas drove in the 2021 Dakar Rally included several components that were designed and additively manufactured by Poly-Shape.

Leveraging the Technology

Two of the most important features in off-road racing vehicles are lightness and durability. Strategic parts of the DXX buggy were selected for 3D printing, including an ergonomic gear lever with a knob that was customized to match the driver’s hand for a better grip. Poly-Shape printed the part in titanium on a FormUp 350 laser powder bed fusion machine from AddUp.

The additively manufactured gear lever in Dumas’s buggy was designed using topology optimization software to reduce weight and material. It’s also customized to the driver’s hand for better performance, and includes a gland where the strain gage cable can be embedded so it doesn’t distract the driver.

Photo Credit: Poly-Shape

Poly-Shape also used topology optimization to reduce the mass of the lever. By adding material only where it’s needed, the company reduced the mass of the lever by 60% compared to the original lever made with conventional manufacturing methods. Topology optimization also allowed savings in raw material, which reduced production costs.

In addition to the customized shape, additive manufacturing also enabled the integration of more functions into the part. The lever was designed to include a gland for the strain gage cable. This cable moves around a lot during the course of a race, and it can be distracting to the driver. With the cable embedded into the lever, the strain gage can be fed without disturbing the driver.

Pedal to the Metal

In addition to the gear lever, experts from Poly-Shape used AM to produce the car’s three pedals. The pedals, which were also printed in titanium on a FormUp 350, were designed according to the forced exerted on them by the driver during the race. So the brake, which is the most used pedal, was designed to withstand stronger forces than the other two pedals.

The buggy’s three pedals were 3D printed in titanium for improved strength, while topology optimization reduced their weight by an average of 42% over the original, traditionally manufactured pedals.

Photo Credit: Poly-Shape

Poly-Shape also designed the pedals to increase performance with the addition of a special surface that increases the grip between the pedals and the driver’s foot to prevent slipping. Additionally, topology optimization on the bottoms of the pedals helped to reduce the weight of the parts. Overall, the new pedals are, on average, 42% lighter than the originals, while the use of titanium makes them stronger.

Exhaust Ball Joint

The last part installed on the buggy was a newly designed exhaust ball joint. Pipo Moteurs, a French engineering company and manufacturer of engines for cars that compete in the current World Rallycross Championship (WRX), was searching for a solution to improve the exhaust line bellows, which are prone to breaking and even causing fires during races. Pipo Moteurs contacted Poly-Shape, with whom they have been collaborating for many years, to optimize the design of a metal, 3D-printed ball joint. Named for the collaboration between the two companies, the “PSPM” ball joint for high strength and temperature resistance to prevent failure during a race.

It does this using a design that involves two sliding layers that are sealed by the differential expansion phenomena created between them. The two layers are connected with an interference fit that can only be produced by additive manufacturing. The joint is printed as a single part on a FormUp 350 in Inconel, enabling the part to resist the high temperatures of rally engines.

The PSPM ball joint has been tested on Pipo Moteurs engines since 2018, and the companies say it has produced excellent results —it does not leak under the high exhaust gas pressure of a rally engine. A PSPM ball joint that was installed on a WorldRX Championship car in the middle of the 2018 season has not failed yet.

Related Content

Do Distributors Dream of Digital Inventory? Würth Additive Group Does

It’s more than a dream for Würth Additive Group and its parent company, in fact. Along with supplying additive equipment, the group is now developing solutions for sourcing 3D printed parts in a reliable, elastic digital inventory model.

Read MoreWhat Does Additive Manufacturing Readiness Look Like?

The promise of distributed manufacturing is alluring, but to get there AM first needs to master scale production. GKN Additive’s Michigan facility illustrates what the journey might look like.

Read MoreThis 3D Printed Part Makes IndyCar Racing Safer: The Cool Parts Show #67

The top frame is a newer addition to Indycar vehicles, but one that has dramatically improved the safety of the sport. We look at the original component and its next generation in this episode of The Cool Parts Show.

Read MoreSeurat: Speed Is How AM Competes Against Machining, Casting, Forging

“We don’t ask for DFAM first,” says CEO. A new Boston-area additive manufacturing factory will deliver high-volume metal part production at unit costs beating conventional processes.

Read MoreRead Next

Porsche Advances Electrification with Generative Design

The sports car manufacturer achieves weight savings and assembly consolidation using additive manufacturing instead of casting for an electric drive housing.

Read MoreGenerative Design Improves Micromobility FUV: The Cool Parts Show #19

Arcimoto’s lightweight “Fun Utility Vehicle” gets even lighter thanks to parts that could only come from additive manufacturing. On this episode of The Cool Parts Show, some of the craziest automotive parts you have seen.

Read MorePushing Laser Powder Bed Fusion into New Realms of Productivity

The Betatype technology stack supports businesses looking to expand on the potential of additive manufacturing for series production through design-led thinking and unique optimization algorithms to maximize the capacity of LPBF systems.

Read More