Metal

What Should We Call Additive Manufacturing Businesses? AM Radio #3

Machining is done in a shop, injection molding is done at a molder and casting is done at a foundry. But what do we call businesses that do additive manufacturing? Peter Zelinski and Julia Hider discuss why it’s difficult to name these businesses (and suggest a few options) on this episode of AM Radio.

Read MoreSLM Solutions Outfitting Morf3D’s Headquarters

Morf3D’s new Applied Digital Manufacturing Center is designed to help streamline and accelerate serial additive manufacturing production lines across the globe.

Read MoreEOS Partners with Morf3D in Applied Digital Manufacturing Center

The center is designed to harness applied research, advanced engineering and application development, serial production and industry partnerships to drive the industrialization of digital manufacturing in high-growth markets.

Read MoreDesktop Metal Acquires Aidro Metal Additive Manufacturer

Acquisition gives Desktop Metal unique application expertise to accelerate adoption of additive manufacturing 2.0 by major OEMS in hydraulics, oil and gas, aerospace, machinery and other industrial sectors.

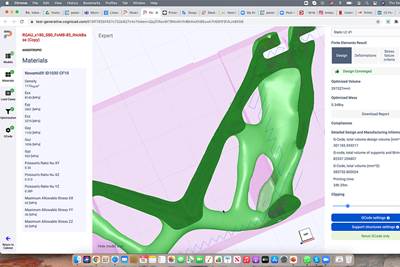

Read MoreCovestro, ParaMatters Jointly Develop Anisotropic Optimization Software

Software is designed to unlock the full potential of filament extrusion 3D printing with fiber-reinforced materials.

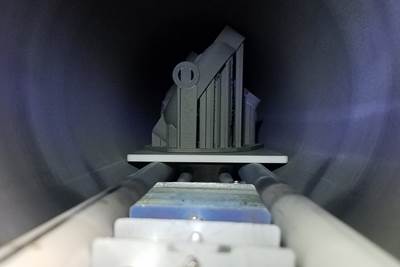

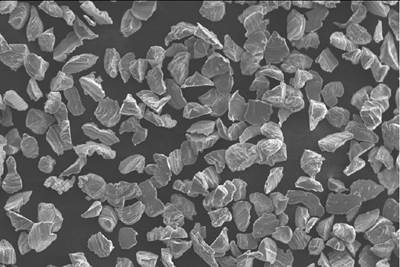

Read MoreAffordable 3D Printing Powders Made from Barstock, No Melting Required

DirectPowder, a proprietary technique from Metal Powder Works, transforms solid metal or polymer into 3D printable powder. The solution promises distributed production of both materials and parts, even in the field.

Read MoreMarkforged’s Eiger Fleet Enables More Control, Automation of Distributed Manufacturing

Cloud-based software solution manages distributed manufacturing operations on an enterprise and global scale with increased efficiency and insight.

Read MoreDesktop Metal Qualifies Titanium for Manufacturing with Studio System 2

Desktop Metal is first company to commercialize titanium for bound metal production of high-strength, lightweight components, opening the door to more accessible additive manufacturing production of high-performance titanium parts.

Read MoreFarsoon Reaches Milestone 500+ Installed Systems

Manufacturer of metal and plastic laser sintering systems is seeing an increasing demand for large-volume functional parts fabrication, especially in the aerospace and automotive industries.

Read MoreOptomec Metal Printers Designed for Automated, High-Volume Production

RAPID 2021: Machines offer fully automated, high-volume production for both metal additive and 3D printed electronics.

Read More