EOS Partners with Morf3D in Applied Digital Manufacturing Center

The center is designed to harness applied research, advanced engineering and application development, serial production and industry partnerships to drive the industrialization of digital manufacturing in high-growth markets.

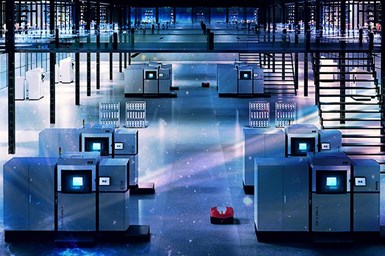

The ADMC will house Morf3D’s business operations and is designed with a vision toward innovation and growth for the AM industry.

EOS has committed to a technology development partnership in Morf3D’s new Applied Digital Manufacturing Center (ADMC) in Long Beach, California. Morf3D is a subsidiary of Nikon Corp. which specializes in metal additive manufacturing (AM) optimization and engineering for the aerospace, defense and space industries.

The Morf3D ADMC is a 90,000-square-foot, state-of-the-art facility designed to harness applied research, advanced engineering and application development, serial production and, most significantly, new industry partnerships with global leaders to drive the industrialization of digital manufacturing in high-growth markets.

Morf3D’s technology investments in EOS’ Direct Metal Laser Solidification (DMLS) metal AM platforms will include the biggest installation of EOS M 400 series systems under one roof, automated shared modules, material management systems and EOS’ AMCM line of specialized large-format metal industrial 3D printers — all working in concert to accelerate the progress toward the industrialization of AM.

When complete, the ADMC is said to provide full-scale production enablement capabilities within the world’s first industrial ecosystem for the advancement of AM. For its part, EOS will deploy advanced, automated AM technology, together with the engineering resources necessary to help ensure the full optimization for customer programs.

“The AM industry is developing fast and Morf3D’s ADMC is a next-level development toward scaling production,” says Glynn Fletcher, EOS North America president. “Morf3D has evolved spectacularly, and we are very proud to have been a part of their vision from the very beginning. EOS has never wavered from our commitment to serial AM production and the ADMC is another giant step on our industry’s march toward the digitization of manufacturing.”

Morf3D is looking to its industry partnerships within the ADMC to help bring forth new industry capabilities and innovations. “Our aim is not to simply add more capacity or capability but rather solve the complex issues that are central to industrializing Additive Manufacturing,” says Ivan Madera, Morf3D CEO.

Related Content

-

Part Removal Efficiency In a 600 mm Plus World

Clay Olson of EDM Performance Accessories discusses the difficulties and opportunities in cutting off parts from the build plates of large AM systems. Molybdenum wire EDM offers an effective solution to the challenge of large-part cutoff.

-

How Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

-

“Mantis” AM System for Spacecraft Uses Induction for Deposition

The metal 3D printing system melts wire without lasers. 30-foot-diameter parts are built on a rotary-feed system that eliminates the need for a large machine frame or gantry.