Covestro, ParaMatters Jointly Develop Anisotropic Optimization Software

Software is designed to unlock the full potential of filament extrusion 3D printing with fiber-reinforced materials.

Share

Read Next

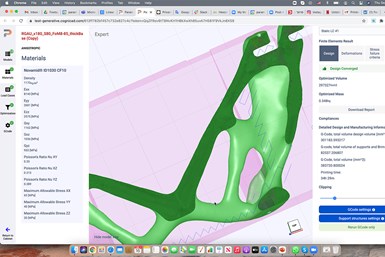

Covestro and ParaMatters’ jointly developed optimization software is designed to deliver a complete anisotropic design and workflow that unlocks the full potential of filament extrusion 3D printing with fiber-reinforced materials.

Covestro and ParaMatters have jointly developed optimization software for anisotropic materials. By combining ParaMatters’ expertise in design and manufacturing optimization technology with Covestro’s knowledge in engineered materials, the two companies have set out to deliver a complete anisotropic design and workflow that unlocks the full potential of filament extrusion 3D printing with fiber-reinforced materials.

The companies say that designers and engineers can use the new optimization tool to quickly obtain the most optimal part design based on material deposition and fiber orientation, and generate the most efficient printer toolpath. The result is materials, weight and cost savings — while maintaining part performance — that is said to surpass what can be achieved today by engineers relying on experience or intuition.

Additively manufactured parts produced from fiber-reinforced materials are said to provide a valid alternative to metal parts due to a better strength-to-weight ratio, thereby reducing part costs and supply chain complexities. However, until now none of the existing topology optimization tools were able to consider these anisotropic materials, the companies say.

Following a successful initial evaluation by leading aerospace users — including the Composite Technology Center (CTC) — on multiple filament extrusion printers, Covestro and ParaMatters are introducing a beta version so more users can exploit the full benefits of anisotropic materials.

The CTC was one of the first companies to fully evaluate and validate the value of ParaMatters anisotropic generative design and manufacturing engine. “ParaMatters’ anisotropic optimization capabilities allow us to combine multiple stages into a single step, enabling us to cut development times by orders of magnitude, and create stronger and more light-weighted components,” says Marc Fette, CTC CEO.

The collaboration between software, materials and equipment players takes manufacturing, material science and generative design to the next level, the companies say. “We can now realize large savings in materials, printing time and cost while maintaining performance and quality,” says Hugo da Silva, head of additive manufacturing at Covestro. “Definitely a promising route toward scalable and more sustainable 3D printing.”

Related Content

-

This Year I Have Seen a Lot of AM for the Military — What Is Going On?

Audience members have similar questions. What is the Department of Defense’s interest in making hardware via 3D printing over conventional methods? Here are three manufacturing concerns that are particular to the military.

-

With Electrochemical Additive Manufacturing (ECAM), Cooling Technology Is Advancing by Degrees

San Diego-based Fabric8Labs is applying electroplating chemistries and DLP-style machines to 3D print cold plates for the semiconductor industry in pure copper. These complex geometries combined with the rise of liquid cooling systems promise significant improvements for thermal management.

-

3D Printing Molds With Metal Paste: The Mantle Process Explained (Video)

Metal paste is the starting point for a process using 3D printing, CNC shaping and sintering to deliver precise H13 or P20 steel tooling for plastics injection molding. Peter Zelinski talks through the steps of the process in this video filmed with Mantle equipment.