Metal

Sandvik’s Cemented Carbide Offers Wear Resistance, Design Freedom

Company says its cemented carbide is one of the hardest materials available in 3D printed shape.

Read MoreHow Siemens Energy Applies Additive Manufacturing for Power Generation and More

At an applications center in Orlando, Florida, a small team of AM specialists is spanning industries by 3D printing parts to support both Siemens Energy power generation systems and external customers.

Read MoreUniformity Labs’ Stainless Steel Powders Deliver Improved Mechanical Properties

The powders are said to deliver improved mechanical properties at much higher throughput in laser powder bed fusion (LPBF) additive manufacturing.

Read MoreArch Medical Solutions Acquires Amplify Additive

With this acquisition, Arch Medical Solutions enters the additive manufacturing market to offer more innovative solutions for customers within the medical device contract manufacturing market.

Read More3D Printed Brackets Secure Fuel for Nuclear Power: The Cool Parts Show #45

Can additive manufacturing improve the design of nuclear power plants? These steel brackets are the first step.

WatchGE Aviation Singapore Approved for Metal Additive Engine Component Repairs

The company says metal 3D printing enables customization and complexity for repair parts, with repairs customized for each individual part because each part wears differently during service.

Read More3D Printing Lightweights Large Cutting Tools Used in Machining

Larger machined parts require larger, heavier cutting tools. 3D printing enables Star SU Neher to produce lightweight large tool bodies and add features that improve tool life and performance.

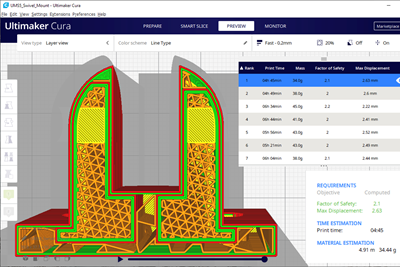

Read MoreMarkforged Acquires Teton Simulation

Integration of Teton’s cloud native simulation software into Markforged’s Digital Forge platform will enable manufacturers to validate advanced composite parts for demanding production applications.

Read MoreMicroturbine Relies on 3D Printed Housing to Preheat Fuel

The aluminum housing designed with nTopology and made on a Velo3D laser powder bed fusion system helps realize what its creators say will be the highest-power-density small turbine yet produced.

Read MoreDesktop Metal’s DM HH Stainless Steel for Wear, Corrosion Resistance

The company says using DM HH Stainless Steel (DM HH-SS) with its Production System enables customers to go to market at scale and eliminate operations such as plating, which can create supply chain complexity and may be harmful to the environment.

Read More