Mark Davis, owner of the NFL’s Las Vegas Raiders, commissioned the Al Davis Memorial Torch in memory of his father and former Raiders owner. The nine-story-tall monument is located at Allegiant Stadium in Las Vegas. Photo Credit: Dimensional Innovations

The new Allegiant Stadium in Las Vegas, Nevada, home to the NFL’s Las Vegas Raiders, is the epitome of modern comfort. The 1.8 million-square-foot, 65,000-seat behemoth was inspired by futuristic luxury vehicles, and its overall impression is one of innovation and modernity.

Current team owner Mark Davis, however, wanted to bring along a bit of the past to the Raiders’ new home. He envisioned a memorial to his late father and previous Raiders owner Al Davis that would illustrate the scale of love his father had for his favorite NFL team.

The Al Davis Memorial Torch, a nine-story replica of a torch with a shimmering light feature on top to simulate ever-burning flames. Photo Credit: Dimensional Innovations

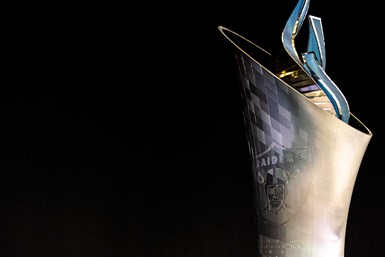

That memorial is the Al Davis Memorial Torch, a gargantuan structure of a torch with a shimmering light feature on top to simulate ever-burning flames. The sheer size of the nine-story-tall memorial made manufacturing daunting for the vast majority of shops in the United States. Add in the strict parameters set by the Raiders organization and Manica Architecture, the firm responsible for building the new stadium, and the project became impossible for all but a handful. The memorial had to weigh under 250,000 pounds, be able to withstand heavy wind load, provide an exceptional reflective surface similar to Anish Kapoor’s Cloud Gate in Chicago, adhere to exacting safety standards like being fireproof, and stay true to the initial design — and it had a firm budget and timeline. Dimensional Innovations (DI) was game to take on the impossible.

The memorial had to weigh under 250,000 pounds, be able to withstand heavy wind load, provide an exceptional reflective surface similar to Anish Kapoor’s Cloud Gate in Chicago, adhere to exacting safety standards like being fireproof, and stay true to the initial design. Plus, it had a firm budget and timeline. Photo Credit: Dimensional Innovations

Founded in 1993, DI has grown from a modest sign fabrication company into a full-service experience design, technology and build firm. DI’s partners include professional and collegiate sports franchises, entertainment giants, Fortune 500 companies and brands, and world-renowned hospitals. Few projects have tested DI’s ingenuity like the Al Davis memorial, though.

DI’s public relations and social media strategist Weston Owen recalls, “After numerous approaches were considered and fell short of the Raiders’ stringent guidelines, we were almost ready to walk away from the project. That’s when our team presented an almost unthinkable solution.”

The finished piece would become the tallest freestanding 3D printed structure in the entire world. Photo Credit: Dimensional Innovations

Their solution was to 3D print the memorial and then use five-axis machining to finish the parts, which would allow them to achieve incredibly tight tolerances. In Owen’s words, the idea was “crazy, but trailblazing if executed properly.” The concept was so trailblazing, in fact, that the finished piece would become the tallest freestanding 3D printed structure in the world.

More than Pressing Print

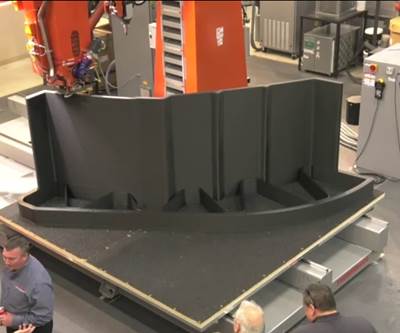

DI purchased a 1020 Thermwood Large Scale Additive Manufacturing (LSAM) twin-gantry machine specifically to make the memorial. The unit hosts a printhead on one side and a five-axis router head on the other. At the time, only two other entities in the United States owned the same style machine: Boeing and the U.S. Department of Defense. It was designed to create single-use molds for the aerospace industry, but Owen says, “In typical DI fashion, we used the printer for a drastically different purpose. Because of this, months of trial-and-error were needed to program the printing software for our desired outcome and ensure it could build the foundational blocks of the torch.”

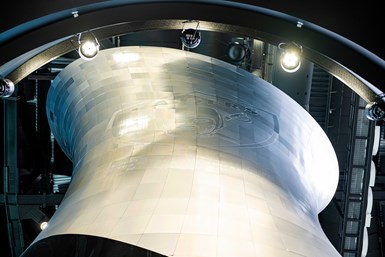

Creating the memorial over the course of three years, DI collaborated with Bob D. Campbell & Company, CMSC at Purdue University, Zahner and UltraTech Aerospace. All provided substantial expertise to DI throughout the R&D process to overcome numerous challenges, with great attention to detail. CNC programmer at Dimensional Innovations Chris Lanio explains, “The basic structure of the tower is essentially an hourglass, almost an elliptical shape. So, there are no two parts on it that are the same.” Each piece is approximately four feet by five feet with a base thickness of six inches. All the pieces are made from polycarbonate with 20 percent carbon added by weight as a strengthening agent. “We’ve tried to do unfilled polymers in the past, but they just distort and warp. This carbon fiber gave us a very aesthetically pleasing effect, with stripes that run parallel across the entire structure,” Lanio says.

The LSAM ran 24/7 to produce 226 blocks, each weighing about 350 pounds, and 5,580 printed layers. After printing, each piece was machined on the five-axis router side of the machine to a tolerance of 0.005". Photo Credit: Dimensional Innovations

The first step after the design and manufacturing plan were finalized was building the 3D printed structure of the torch. The LSAM ran 24/7 to produce 226 blocks, each weighing about 350 pounds, and 5,580 printed layers. After being printed, each piece was machined on the five-axis router side of the machine to a tolerance of 0.005 inch. Lanio says, “With the LSAM, we could print a part, position the curtain over, and the next day machine it in that exact spot.” This efficient manufacturing workflow means that staff were able to avoid unwieldy work-handling and extra hours.

When DI purchased its LSAM, it was advised to use Mastercam CAD/CAM software from CNC Software to run its subtractive manufacturing portion. The machine manufacturer has developed a C-hook add-on to program the printer side of the machine that works flawlessly within this specific CAD/CAM system. To maintain continuity, DI switched its three-axis programmers to Mastercam as well which ended up making cutting faster and easier.

Most of the parts were similar enough that tweaking existing files made more sense than programming each part anew. Lanio’s CAD software made this easy. “I was able to store proven data, roll it back in and apply them to the geometry. It saved so much time in the long run on the programming aspect,” he explains. When editing models in the CAD portion of the software, Lanio relied on the Hole Axis feature to quickly lay out geometry and add holes on multiple angles.

Programmer Chris Lanio with the 1020 Thermwood Large Scale Additive Manufacturing twin gantry unit purchased specifically for this project. Photo Credit: Dimensional Innovations

The majority of the curved sections were machined with the Multiaxis Flow tool path. “This allowed us to use a very large stepover with a 0.5-degree lead cutting with a 2-inch face mill,” Lanio says. The CAD/CAM software is designed to deliver the most efficient multi-axis roughing and finishing tool paths possible, so that users spend less time programming and more time turning out parts. One such tool path is Five-Axis Swarf, which Lanio used to transition between faceted and smoothly curved faces. “This tool path allowed us to keep the tool perpendicular to the faceted floors while maintaining a sharp corner for the aluminum plates clearance,” he says.

A substantial amount of machining was done with traditional three-axis milling as well, with operations like pocketing and slotting, which the multi-axis CAD/CAM system was fully capable of supporting. To keep everything organized, Lanio used the Planes function in the software. The Work Coordinate System within Mastercam uses a 3D Cartesian coordinate system to locate parts in the work space. The Planes function helps users determine view angles, draw geometries and associate tool angles to materials within that coordinate system.

“A lot of the parts had 30 or 40 facets on them. I created planes and then imported the tool paths to apply to each. It was a pretty smooth transition that let us keep working at a good pace and get two parts per day off of the machine,” Lanio says .

The material itself was so abrasive that solid diamond inserts were needed for DI’s Sandvik tools to cut it. “We have tools that are really specific for this machine, so I have all of those tools modeled in my library and can import them in for different jobs,” Lanio says. The Mastercam Tool Library enables the import of tool data from original tool manufacturers like Sandvik. Programmers can add their own notes on the best tool paths and motions with which to pair these tools, as well as how well they run on each machine. “It has great cutting strategies stored for these different insert headers,” he says.

After everything had been designed and coded for machining, Lanio then checked and re-checked his program. “It helps to have an actual G code simulation system, because then I can just output these tool files and part files to our verification software.” Vericut simulation software from CGTech lends additional strength to the in-system verification functions in Lanio’s CAD/CAM system. The verification add-on confirms toolpath accuracy and dimensional measurements so that what a programmer sees onscreen is exactly what will unfold on the machine.

Once each part was carefully constructed and inspected, the layers were put together carefully to ensure a seamless fit. Photo Credit: Dimensional Innovations

Once each part was carefully constructed and inspected, the layers were put together carefully to ensure a seamless fit. DI even engineered and programmed a robot specifically designed to apply a protective ceramic coating to the exterior aluminum panels. “This reflective veneer made the torch look uniform and whole, even though it was composed of nearly 1,200 individual panels,” Owens says. The assembled pieces were then shipped to Allegiant Stadium for final assembly of the whole monument. Not including the upfront R&D, the project took about 16 months and over 50,000 staff hours to create.

“It was — no pun intended — a monumental effort,” Owen says . “It’s our crown jewel at DI because of the sheer feel of it and how we essentially did something in a way no one ever has.”

Lanio agrees. “There were so many great people working on it from design to engineering to assembly. We definitely had some doubts, some nervous nights, even some failures where we had to scrap something and try again, but the beauty of it is that we all kept hammering at it,” he says. “There was so much ingenuity and mutual respect in those situations where we were all bouncing ideas off of each other to create the highest quality product possible.”

Related Content

Bike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read More3MF File Format for Additive Manufacturing: More Than Geometry

The file format offers a less data-intensive way of recording part geometry, as well as details about build preparation, material, process and more.

Read MoreThis 3D Printed Part Makes IndyCar Racing Safer: The Cool Parts Show #67

The top frame is a newer addition to Indycar vehicles, but one that has dramatically improved the safety of the sport. We look at the original component and its next generation in this episode of The Cool Parts Show.

Read More3D Printed Lattices Replace Foam for Customized Helmet Padding: The Cool Parts Show #62

“Digital materials” resulting from engineered flexible polymer structures made through additive manufacturing are tunable to the application and can be tailored to the head of the wearer.

Read MoreRead Next

CGTech Extends Simulation to Thermwood LSAM (Includes Video)

Large-scale additive manufacturing platform is the largest 3D printer yet simulated. Watch video for example of how simulation using program G-code catches an error that would otherwise lead to a failed build.

Read MoreFor Sustainable 3D Printed Architecture Think Renewable, Not Permanent

The design choices of today won’t be the trends of tomorrow. Aectual chooses to embrace changing tastes by making it easy to procure and recycle 3D printed architectural elements.

Read More8 Cool Parts From RAPID+TCT 2022: The Cool Parts Show #46

AM parts for applications from automotive to aircraft to furniture, in materials including ceramic, foam, metal and copper-coated polymer.

Read More