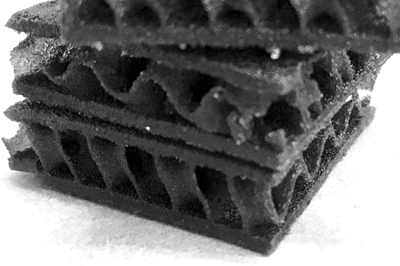

Foam

Why Customization at Mass-Market Scale Is Finally Possible With 3D Printing

Printer speed and materials coupled with scanning technologies are contributing to more affordable and accessible 3D printed, personalized goods.

Read MoreEOS Launches Digital Foam Architects Network

EOS created the collaborative additive manufacturing alliance to accelerate time-to-market for 3D printed foam applications.

Read MorePartners Improve Wheelchair Seats, Cushions Using 3D Printed Programmable Foam

The 3D printed programmable foam is said to enhance orthopedic seats and cushions, offering improved comfort and reliability for users.

Read More3D Printed Lattices Replace Foam for Customized Helmet Padding: The Cool Parts Show #62

“Digital materials” resulting from engineered flexible polymer structures made through additive manufacturing are tunable to the application and can be tailored to the head of the wearer.

WatchBauer Hockey Uses EOS 3D Printed Digital Foam for Customizing Helmets

The new in-store experience, combined with proprietary 3D printing technology, opens the door for personalized hockey products.

Read More8 Cool Parts From RAPID+TCT 2022: The Cool Parts Show #46

AM parts for applications from automotive to aircraft to furniture, in materials including ceramic, foam, metal and copper-coated polymer.

WatchPrintFoam Develops 3D Printer for High-Throughput Foam Applications

PrintFoam says its 3D printing technology creates closed-cell foam parts that are faster, lighter and less expensive to produce than other photopolymer technologies.

Read More3D Printed Lattice Structures Replace Foam Components: AM Radio #9A

On this episode of AM Radio, Stephanie Hendrixson and Julia Hider examine the use of 3D printed components with lattice structures to replace foams.

ListenEOS’ Digital Foam Flexible Lattice Polymer Enables Mass Customizations

Highly flexible lattice polymer material can be used to manufacture more comfortable, safer and lighter products that can be individually customized.

Read More3D Printed Tooling Supports Prototype Foam Seating

Automotive manufacturers and other OEMs require mold tooling to build foam components like seat cushions. 3D printed tools could be a faster, more affordable way to prototype and produce these parts.

Read More