PrintFoam Develops 3D Printer for High-Throughput Foam Applications

PrintFoam says its 3D printing technology creates closed-cell foam parts that are faster, lighter and less expensive to produce than other photopolymer technologies.

Share

Read Next

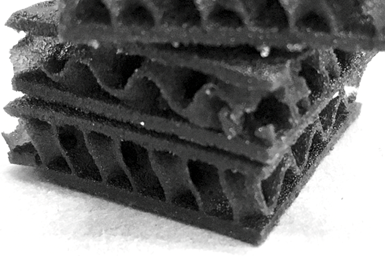

PrintFoam says it is possible to produce plywood-sized sheets of 3D printed foam in a matter of minutes. Photo Credit: PrintFoam

PrintFoam has developed a high-throughput foam 3D printer for the industrial-scale printing of foams. The company specializes in 3D printing resins that make foam parts, with those resins said to provide performance boosts in applications where users might expect to find traditional foam solutions.

While many AM users are attempting to mimic the behavior of traditional foams using plastic lattices, the company says those users should just utilize foam for the application. Engineered from the ground up to meet customers’ needs, the company says its system can offer users both scale and speed. The system is also said to provide comprehensive solutions for customers who are looking for ways to print a lot of material quickly without sacrificing resolution.

The company’s closed-cell foam materials consist of gas bubbles in a liquid photopolymer resin, creating closed-cell foam parts that are faster, lighter and less expensive to produce than other photopolymer technologies, the company says. By using a combination of novel, optical patterning techniques, along with omitting a standard vat printing process, PrintFoam says it is possible to produce plywood-sized sheets of 3D printed foam in a matter of minutes.

By speeding up production times from hours to minutes and creating large, architecturally sized panels, the company says it can now enter a variety of new markets that were previously inaccessible.

The technology is currently in limited beta access, but the venture is actively accepting a limited number of new partnerships. PrintFoam is already working with customers to explore novel approaches for noise mitigation, carbon sequestration, concrete construction and more.

Related Content

-

EOS Launches Digital Foam Architects Network

EOS created the collaborative additive manufacturing alliance to accelerate time-to-market for 3D printed foam applications.

-

Partners Improve Wheelchair Seats, Cushions Using 3D Printed Programmable Foam

The 3D printed programmable foam is said to enhance orthopedic seats and cushions, offering improved comfort and reliability for users.

-

Bauer Hockey Uses EOS 3D Printed Digital Foam for Customizing Helmets

The new in-store experience, combined with proprietary 3D printing technology, opens the door for personalized hockey products.