Defense

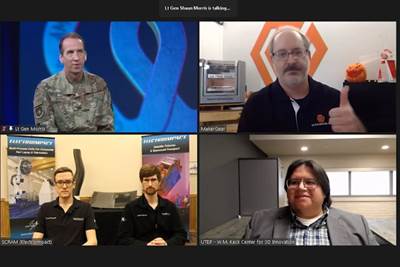

U.S. Air Force Rapid Sustainment Office Concludes First Ever Advanced Manufacturing Olympics

Nearly $1M in prizes awarded to winners of five competitions related to additive manufacturing. AM editor-in-chief Peter Zelinski co-hosted the Air Force’s week-long event.

Read MoreAustralian Army Field Trials Prove Metal 3D Printing Capabilities

Soldiers overcame extreme field conditions to design, print and finish a series of groundbreaking 3D-printed parts using ‘WarpSPEE3D’ metal 3D printer.

Read MorePhillips Federal, Bel Air Finishing Combine Efforts for Army Facility

Unique post processing technologies support additive manufacturing programs at Army’s Rock Island Center of Excellence.

Read MoreAustralian Army Tests Metal 3D Printing in Latest Field Trial

The ‘WarpSPEE3D’ program aims to significantly increase unique parts available to the Army compared to what the regular supply chain can provide.

Read MorePhillips Corporation Enters Partnership with the U.S. Army to Provide AM Expertise and Support at Rock Island Arsenal

Phillips Corporation, Federal Division has executed a Public Private Partnership Agreement (P3) to support the Army Center of Excellence for Advanced Manufacturing (CoE) at the Rock Island Arsenal-Joint Manufacturing and Technology Center.

Read MoreWorcester Polytechnic Institute Brings Cold Spray 3D Printing Techniques to Battlefield

Funding from the Army will support advanced work on cold spray; the portable repair and manufacturing technique could increase the readiness of military vehicles and other units.

Read MoreAir Force Research Laboratory, Boeing and Thermwood Partner on Low Cost Responsive Tooling Program

The Air Force Research Laboratory, Boeing and Thermwood partnered to evaluate the functionality of Vertical Layer Printing (VLP) using high temperature, autoclave-capable materials on a Large Scale Additive Manufacturing (LSAM) machine.

Read MoreMarkforged Launches Flame-Retardant Material for 3D printing

Markforged, manufacturer of metal and carbon fiber 3D printers, has released Onyx FR, a V-0 rated flame-retardant material designed for industries such as aerospace, automotive and defense.

Read MorenScrypt 3D Prints Antennas on Complex Surfaces for Air Force

nScrypt’s research group, Sciperio, has recieved funding from the Air Force to continue its work to conform 3D-printed antennas to complex surfaces. Directly printing active phased array antennas on curved surfaces can make it feasible to include advanced communication technology directly into the body of a vehicle or aircraft, the company says.

Read MoreThermwood and U.S. Navy Complete Validation for AM Marine Program

The validation program centered on printing an unclassified scale nose of a submarine using Thermwood’s Large Scale Additive Manufacturing (LSAM) system.

Read More