Worcester Polytechnic Institute Brings Cold Spray 3D Printing Techniques to Battlefield

Funding from the Army will support advanced work on cold spray; the portable repair and manufacturing technique could increase the readiness of military vehicles and other units.

Share

Worcester Polytechnic Institute (WPI) has received a three-year, $25 million award from the U.S. Army Combat Capabilities Development Command Army Research Laboratory (CCDC-ARL) to advance a 3D printing technique that could be used to repair vehicles and other critical technology in the field, avoiding the sometimes extensive wait for new parts and increasing the readiness of military units.

The new award builds on the university’s experience with powder metallurgy and computational tools for materials design gained with nearly $30 million in previous Army funding.

The current Army Research Laboratory (ARL) award will focus on a technique called cold spray, which can be used to repair metal parts or even make new parts from scratch by building up metal layer by layer in a process known as additive manufacturing, commonly known as 3D printing. Cold spray uses a pressurized gas to accelerate metal powders to near supersonic speeds. The force of impact causes the powders to adhere to the metal upon impact. The process can be reduced to a portable handheld applicator.

“The Army is interested in cold spray 3D printing as a repair technique,” says Danielle Cote, assistant professor of materials science and engineering and director of WPI’s Center for Materials Processing Data, who is the principal investigator for the ARL project. “It’s cheaper to repair a part than to replace it, and you get the equipment back in service faster. The Army’s primary interest is unit readiness. If you’re on a mission and need to move quickly to a safer place, and a critical part on your vehicle breaks, you’re stuck unless you can repair it quickly. That’s where cold spray comes in.”

WPI’s primary focus in this research will be on developing, characterizing, and testing new alloys optimized for use in cold spray. Cote says the characteristics of the metal powders used in cold spray are critically important since the metal is not melted before being sprayed onto a part that needs repair, nor is it heat treated after application. “With most manufacturing methods, metal alloys are alerted by first being melted, and then often heat treated to strengthen or otherwise improve their properties. With cold spray, what you end up with in the repair is exactly what you start with, so the characteristics of the powders are quite important.”

WPI will develop and study powders using a variety of state-of-the-art equipment, including instruments acquired as part of the new ARL award. These include tools to study the chemical and structural properties of the powders at the scale of nanometers, such as a SEM/EDS (scanning electron microscope and energy dispersive spectroscopy) unit, a synchronous laser diffraction and dynamic image particle analyzer to determine powder morphologies, and nanoindenters to measure nano-scaled mechanical properties.

The WPI research team, which includes postdoctoral fellow Kyle Tsaknopoulos, will also work with several subcontractors, including the University of California Irvine, the University of Massachusetts Lowell, Penn State University, and Solvus Global. A spinoff of WPI including two recent WPI PhD recipients in materials science and engineering — Aaron Birt (2017) and Sean Kelly (2018) — Solvus Global will provide commercially available powders and modify them to meet the research team’s specifications so they can be tested in actual cold spray applications.

Among the modifications that will be made to the powders are unique thermal processing treatments, a technique WPI pioneered, Cote said. Unlike metals used in other metal manufacturing processing, including casting and forging, the alloys used in cold spray do not have to be capable of being heat treated, which gives the WPI researchers access to a wide range of potential materials. However, the properties of cold spray powders can be fine-tuned with the careful application of heat. “This expertise is part of the reason the ARL continues to support WPI,” Cote says. “We have discovered that the properties of metal powders can be significantly enhanced with thermal processing, and that is what we are looking to do with this new award.”

The alloys chosen for study in this project and the thermal processing regimes used will be determined, in part, using computational models developed at WPI. Grounded in extensive laboratory experimentation and drawing on voluminous databases of metal properties assembled through previous ARL-funded projects at WPI, the models make it possible to custom design powders for specific cold spray applications. “You can do this through trial and error,” Cote says, “but it is much more effective to design new alloys and thermal processing protocols with our models, and then test them to verify their properties. WPI’s modeling capabilities and experience are what sets us apart from other research teams.”

As one example of how custom designed cold spray powders could help improve military readiness, Cote points to helicopter gearboxes, which need frequent repairs. “If you need to replace a part like that, it can take months or even years, and the cost is significant — assuming that the part is available or even still being made. To repair a gearbox with cold spray, you need alloys with high strength, toughness, and ductility. Our methodology will enable us to develop powders that can be used to effectively repair or even manufacture parts like that and get helicopters back in the air quickly.”

Related Content

MC Machinery’s Wire-Laser Metal 3D Printer for Efficient, Versatile Processing

The printer applications include rapid prototyping, mold and die, one-offs, short runs, mass manufacturing, maintenance, repair, tooling and more.

Read MoreNikon Lasermeister Metal DED 3D Printer and Scanner Developed for Industrial Applications, Turbine Blade Repair

This technology gives manufacturers the ability to build onto existing parts with high precision and utilize a variety of materials, reducing lead times and minimizing postprocessing requirements.

Read MoreAccufacture Develops Alchemist 1 Robotic AM Cell Engineered With Meltio’s Wire-Laser Metal 3D printing Technology

This all-in-one additive manufacturing robotic work cell was engineered for seamless integration and rapid deployment for the safe and reliable manufacture and repair of metal parts.

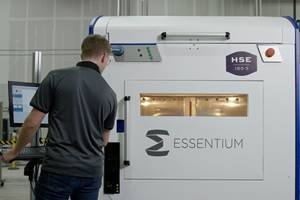

Read MoreGerman National Railway Certifies Essentium HSE Printing Platform, Materials

Essentium’s additive manufacturing solutions will enable Deutsche Bahn to increase its fleet availability through easy and fast replacement of parts and tools.

Read MoreRead Next

Profilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More