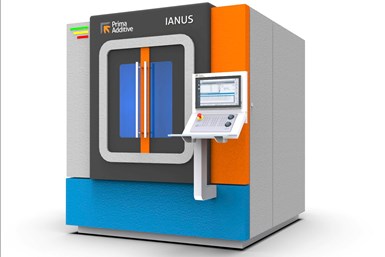

Prima Additive’s Ianus DED System for Multiprocess Flexibility

Formnext 2022: The Ianus robotic cell can be configured to perform two different processes (for example additive and laser hardening) in the same machine.

Prima Additive’s Ianus laser processing robotic cell offers directed energy deposition (DED) technology for additive manufacturing (AM) in a multiprocess configuration. Equipped with a working area of 1,600 × 1,200 × 700 mm, the system can be configured for different laser processes, inlcuding powder-based direct energy deposition, wire-based direct energy deposition, laser welding, and laser hardening.

Depending on the configuration chosen, it is possible to have a system capable of performing two different laser processes, thanks to the possibility of easily changing the head. Due to the integration with Siemens systems, on which this platform is based, it is sadi the Ianus cell can easily integrate with other machines already present in users’ factories.

This system was developed by Prima Additive in collaboration with Siemens, a leading company in automation and digitalization with specific skills in the field of robotics and additive manufacturing. The integration between the technologies of Siemens and those of Prima Additive is expressed through the integration of the robotic arm and the CNC — through the Sinumerik Run MyRobot/Direct Control functionality.

Through this functionality, the user of the machine is able to interface with the robotic cell using a single control console, but also be able to carry out the movement and programming of the robot using typical instructions of a machine tool, thus exempting users from knowing an additional programming language specific for robots. The integrated use of the CAD-CAM-CNC chain (made possible using the NX platform and the Sinumerik One numerical control) is completed by the integration of digital solutions and data management.

The solution, based on the MindSphere open ecosystem, involves the use of Siemens Apps that enable users to view, manage and optimize production (such as Manage MyMachine) and remote monitoring and control systems (such as Manage MyMachine/Remote).

To fully exploit the potential of Sinumerik One, the system utilizes the Create MyVirtual Machine, a key tool made available by the Siemens digital portfolio. This software is able to generate a real digital twin of the system and has proved to be extremely useful for facilitating the engineering work in the various stages of development and optimization of the machine, also enabling a considerable reduction in time to market.

- Read how Prima Additive integrated the Materialise Control Platform (MCP) hardware control into its Print Genius 150 additive manufacturing system to obtain real-time control functions and a streamlined combination with external systems to assist the process, such as monitoring and control systems.

- Learn how Prima Additive’s Print Genius 150 offers multilaser operating simultaneously or alternating on the same work area.

Related Content

-

What We Found at Formnext 2023

New metal processes, new possibilities for existing processes, the next step for copper and more. Here is a summary drawing on all our reporting from November’s event.

-

8 Cool Parts From Formnext 2024: The Cool Parts Show #78

End-use parts found at Formnext this year address various aspects of additive's advance, notably AM winning on cost against established processes.

-

8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.