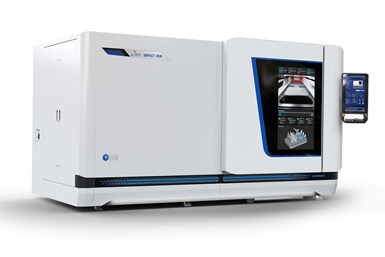

IRPD Impact 4530 for Metal Additive Manufacturing

The laser bed powder fusion machine features a modular, scalable design and is said to offer a high degree of automation and repeatability.

Photo Credit: IRPD

IRPD, a United Grinding brand, has developed the Impact 4530 additive printer for the production of metallic components in 3D printing. This laser bed powder fusion (LBPF) machine features a modular, scalable design and is said to offer a high degree of automation and repeatability, while designed for safe operation in industrial conditions.

The printer features a separate service and loading area, with an automatic system for changing containers for metal powder and components to ensure greater productivity, the company says. It is said the cleaning and maintenance of the system is also easy and uncomplicated due to its design, which is said to greatly simplify machine handling and increase productivity.

The company says the printing process is sustainable and resource-saving due to a closed, inert process cycle using construction containers. It is also said high repeat accuracy is achieved through the use of smart software due to its CORE OS technology. The hardware and software architecture is said to enable intuitive operation, networking with other machine tools and preparing for production largely independently.

The company says the printer is highly productive with up to 4 lasers of 1,000 W each thanks to a multibeam strategy, full-field optics and minimum nonproductive times "job to job" due to fast, automatic container and material changes.

Related Content

-

UltiMaker Targets Light Industrial Applications With 3D Printer Designed for the Factory Floor

The company’s Factor 4 3D printer introduced this week is designed to complement conventional manufacturing equipment including CNC machining and automation.

-

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

-

7 Important Ideas on Postprocessing in AM

Additive manufacturing is defined by 3D printing, but it is more than this step. For almost every AM production part, steps after the 3D printing operation are essential to complete the part and realize its value. Here are several thoughts.