7 Important Ideas on Postprocessing in AM

Additive manufacturing is defined by 3D printing, but it is more than this step. For almost every AM production part, steps after the 3D printing operation are essential to complete the part and realize its value. Here are several thoughts.

-

Postprocessing parts made through 3D printing involves more than touch-up. The way to think about the steps that follow 3D printing is value-adding.

Support structure removal is a postprocessing need for metal parts made via powder bed fusion. Source: Rivelin Robotics

- Automation of postprocessing is the step needed for additive manufacturing to deliver fully automated component repair.

- Automation of postprocessing steps for metal AM parts calls for robotics that, to some extent, can operate with the sensitivity of a craftsperson.

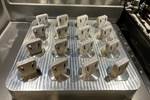

- Depowdering is a crucial postprocessing step that often requires process engineering. Depowdering this component that was made additively calls for a special tool also made additively.

- As geometric complexity advances, the sophistication of cleaning needs to keep up.

- Postprocessing is advancing through partnerships. A few examples: Saint-Gobain and AMT, AddUp and PostProcess Technologies, EOS and PostProcess Technologies, Stratasys and DyeMansion.

- Coming soon: Watch for coating, plating and other surface improvements to AM parts.

Related Content

-

How AM Enables Cobot Automation for Thyssenkrupp Bilstein (Includes Video)

The shock absorber maker has responded to its staffing shortages through extensive use of collaborative robots. In-house 3D printing makes this possible by providing the related hardware needed to complete the cobot-automated cells.

-

The Robot Craftsman: Force Sensing and Vision Help Realize Automated AM Postprocessing (Includes Video)

Automated production via additive manufacturing will need automated postprocessing. This UK startup is equipping robots with the capabilities needed for critical, fine-detail finishing of metal 3D printed parts.

-

Copper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.