Hybrid Software’s CloudFlow Maker Automates 3D Printing Workflow

Formnext 2023: CloudFlow Maker is a modular production workflow suite for file processing, asset management, soft proofing and workflow automation.

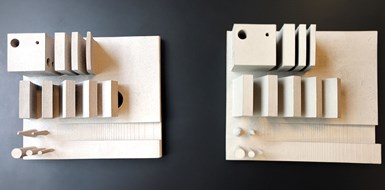

An AISI 316L and 17-4 PH specimen for the evaluation of new functionalities in CloudFlow Maker. Photo Credit: Hybrid Software

Hybrid Software’s CloudFlow Maker is an enterprise workflow solution for industrial-scale binder and material jetting. The software was developed specifically for additive manufacturing (AM) technologies, providing printer producers and users with an exceptional tool to prepare and execute their prints.

It is a modular production workflow suite for file processing, asset management, soft proofing and workflow automation. It is also a web-based application platform specifically tailored for packaging graphics with support for PDF, color separation, trapping, screening, proofing and more.

The company says CloudFlow Maker is a truly industrial solution. Built on OPC-UA standards, the software ensures interaction with all connected devices and machines. And, as the software is fully API-based, it offers smooth connections with all other systems — acknowledging the reality that one-solution-for-everything is nonexistent.

Yet real-world connectivity isn’t the only reason to consider talking to Hybrid Software, according to Kris Binon, AM Business Unit development manager. “Having decades of experience in jetting the right drop on the right spot is just one thing. Industrial printing software is about the ability to provide fast, secure and modular solutions, as well as customer-oriented support, maintenance and upgrades.”

To raise the bar from a technical perspective, Hybrid Software can rely on two other sources. First, parent organization Hybrid Software Group boasts the world’s major provider of printhead electronics for binder jetting: Meteor Inkjet. Combining its hardware with Hybrid’s own software guarantees a direct, secure data stream from CAD up to printhead. Meteor’s expertise on drop formation, binder delivery systems, waveforms and more is unique in the 3Dprint industry, and CloudFlow Maker complements the existing offerings from Meteor Inkjet and its partners.

Also, Hybrid Software’s experienced engineering team has 12-plus years of successful product development for industrial printing applications such labels and packaging to bring to bear for CloudFlow Maker.

“The 3D printing industry is at a crossroads. As printer producers and users turn toward industrialization, they need software to optimize and streamline their workflows for high-volume production,” says Mike Rottenborn, CEO of Hybrid Software Group. “To achieve this, Hybrid is leveraging our expertise in enterprise workflow for printing to develop value-adding functionalities for binder and material jetting.”

- Learn more about binder jetting in our AM 101 section. Binder jetting requires no support structures, is accurate and repeatable, and is said to eliminate dimensional distortion problems common in some high-heat 3D technologies. Here is a look at how binder jetting works and its benefits for additive manufacturing.

- Learn more about material jetting in this article by Tim Simpson, professor of engineering design & manufacturing at Pennsylvania State University. Recent advances in materials processing capabilities have renewed interest in material jetting, the additive process that allows 3D objects to be built by placing different combinations of material drop-by-drop.

Related Content

8 Cool Parts From Formnext 2024: The Cool Parts Show #78

End-use parts found at Formnext this year address various aspects of additive's advance, notably AM winning on cost against established processes.

Read MoreLithoz CeraFab System S320 LCM Printer Designed for Efficient, High-Capacity Industrial Serial Production

Formnext 2024: The system offers a build speed of up to 150 layers per hour and layer thickness of 20–200 µm.

Read MoreWhat We Found at Formnext 2023

New metal processes, new possibilities for existing processes, the next step for copper and more. Here is a summary drawing on all our reporting from November’s event.

Read More8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreRead Next

Alquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read More