Horizon Expands Services With Subcontract Micro AM Production, Design Support

Horizon also offers a suite of proprietary coating processes that enable customers to successfully expand the functionality of parts which are typically produced in plastics on commercially available micro additive manufacturing platforms.

Share

Read Next

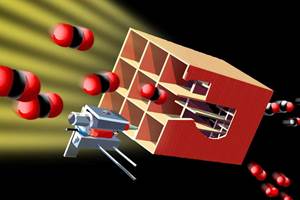

Horizon Microtechnologies now provides a micro additive manufacturing (AM) subcontract service for customers interested in exploring the possibilities that exist through the use of AM for precise and small-scale parts and components but do not have the expertise or infrastructure to undertake production in-house.

Horizon provides a suite of in-house coating processes that add material and functionality to a microstructure. “Very often the microstructure that we coat is made using micro AM, and we offer a truly vertically integrated service assisting companies in part design, in-house micro AM production, and then in-house coating,” says Andreas Frölich, Horizon CEO. “We understand that there are a large number of companies that have heard of micro AM but have not as yet experienced just how precise and repeatable it is as a production process today.”

That has led to Horizon extending its service to produce and design micro AM parts and components for customers whether they need a postprocess coating or not. “There is a requirement for a significant expertise to operate micro AM technologies optimally,” Frölich adds. “At Horizon, we have this expertise and look forward to using it on behalf of companies looking to take exploit the inherent process advantages that micro AM can offer.”

When producing exceptionally precise and tight tolerance parts and components, the company says the added value of a vertically integrated development and manufacturing partner is very important.

The early inclusion of manufacturability considerations along the full microfabrication process chain in design decisions can reduce the number of iterations during the product development phase. This concurrently reduces the time to market and overall product development costs.

Also, a seamless linking of the separate production steps entails tight control and coordination over the various stages of production — from raw material sourcing to final assembly. In the context of precision manufacturing, this approach ensures seamless quality control, optimal material selection, streamlined communication and enhanced process efficiency. Importantly, the interdependencies of the different process steps are established, so the manufacturing process’ execution is fully transparent and can be tightly controlled, the company says.

“At Horizon, we are introducing the use of AM to application areas that have not considered it a viable technology due to its historical lack of precision, and also on the micro level due to its limited palette of materials,” Frölich says. “However, it needs to be considered that micro AM is today able routinely to achieve single micron tolerances and surface finishes with 0.4 micron Ra repeatably with 10 micron XY optical resolution. So it is now possible to use micro-AM for exacting production applications where ultrahigh resolution, accuracy and precision are critical to part functionality.”

The company says it looks forward to opening up the possibilities that can be achieved through the use of micro AM and showing how this agile production process can be cost-effective as it opens up design freedom and stimulates innovation in application areas across an array of industries.

In addition to offering a subcontract micro AM service for customers, where appropriate, Horizon also offers a suite of proprietary coating processes which enables customers to successfully expand the functionality of parts which are typically produced in plastics on commercially available micro AM platforms. The coatings enables homogeneous and precise coating of 3D substrates, and selective coating of parts is possible. Coatings available include HMT-Metal (copper with >25% of bulk copper conductivity); HMT-Protect (ceramic-like protective coatings that increase resilience against external influences such as chemicals, abrasion or elevated temperatures); and HMT-Conductive (transparent conductive coatings with sheet resistances between a few kOhm2 and approximately 100 Ohm2).

Related Content

BMF Receives FDA Clearance for UltraThineer Dental Veneer Material

The zirconia materials are now qualified for use in the production of the world’s thinnest cosmetic veneers, which require significantly less tooth preparation or grinding, thereby preserving more of the patient’s natural enamel.

Read More3D Printed Reactor Core Makes Solar Fuel Production More Efficient

The solar reactor uses water and CO2 from the air and sunlight as the energy source to produce carbon-neutral liquid fuels, for example, solar kerosene for aviation.

Read MoreLithoz CeraFab System S320 LCM Printer Designed for Efficient, High-Capacity Industrial Serial Production

Formnext 2024: The system offers a build speed of up to 150 layers per hour and layer thickness of 20–200 µm.

Read More3D Systems Develops Multimaterial, One-Piece Jetted Denture Solution

The combination of 3D Systems’ high-speed printing technology with unique materials for the NextDent Jet Denture Teeth and NextDent Jet Denture Base solution is designed to offer superior durability and aesthetics for a better patient experience.

Read MoreRead Next

Profilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read More