Hexagon, Stratasys Collaborate on Validation Tool for 3D Printed Plastic Components

Partnership develops software solution to help compress design and testing phases, improve understanding of plastic behavior and speed up innovation across the sector.

Share

Read Next

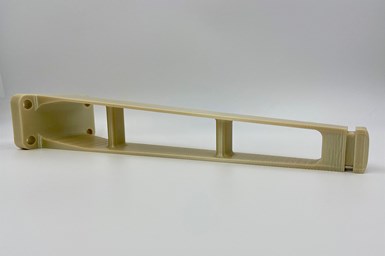

An example of an aircraft ventilation duct geometry that MSC has used for process simulation development.

Hexagon’s Manufacturing Intelligence division is collaborating with Stratasys on a software solution to help aerospace manufacturers boost confidence in the performance and safety of 3D printed plastic components, and compress time to market. Through the virtual engineering and manufacturing support provided by the partnership, customers will be able to reduce a two-to-three-year time scale of designing and testing a part to six to nine months.

Through the partnership, users of Stratasys’ Ultem 9085 filament can use Hexagon’s Digimat material modeling software to predict how printed parts will perform. The Ultem 9085 filament is used to produce parts for aircraft cabin interiors (such as bracketry, pieces for cable routing, covers and duct components), all of which are required to meet stringent certification for aspects such as flammability and toxicity.

Ultem 9085 resin is a flame-retardant, high-performance thermoplastic with a high strength-to-weight ratio, excellent heat resistance and high impact strength, and possesses favorable flame, smoke and toxicity (FST) characteristics, the company says. The material modeling software provides engineers with a validated tool for analyzing how this material will perform mechanically in a product design when printed with two compatible printers.

Using Digimat, engineers will be able to predict how parts made from Ultem 9085 filament may behave when made using approved Stratasys printers. The company says this is made possible through a highly accurate virtual material model (jointly developed by the two companies through physical testing) that includes detailed information about the material’s internal microstructure. The software’s process simulation capabilities help manufacturers avoid defects such as the delineation of warpage of a part, and analyze the print time and material cost for the proprietary printer tool paths of these machines to achieve an optimal result.

The virtual engineering solution can be accessed by customers of the Digimat material modeling software. Stratasys customers can request access to detailed proprietary material cards through its Materials Exchange capabilities and import tool paths directly from their Stratasys Insight software.

Related Content

-

ActivArmor Casts and Splints Are Shifting to Point-of-Care 3D Printing

ActivArmor offers individualized, 3D printed casts and splints for various diagnoses. The company is in the process of shifting to point-of-care printing and aims to promote positive healing outcomes and improved hygienics with customized support devices.

-

3D Printed Lattices Replace Foam for Customized Helmet Padding: The Cool Parts Show #62

“Digital materials” resulting from engineered flexible polymer structures made through additive manufacturing are tunable to the application and can be tailored to the head of the wearer.

-

Understanding PEKK and PEEK for 3D Printing: The Cool Parts Show Bonus

Both materials offer properties desirable for medical implants, among other applications. In this bonus episode, hear more from Oxford Performance Materials and Curiteva about how these companies are applying PEKK and PEEK, respectively.