Grabcad Print Pro Software Helps Improve Part Accuracy, Workflow

The software features new plug-in partners AlphaSTAR and Castor, providing options for real-time part analysis and streamline integrated workflow.

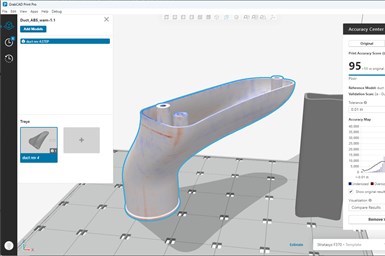

Stratasys’ GrabCAD Print Pro software manages the print preparation process for Stratasys 3D printers and features integrated quality assurance functionality from Riven. The software is designed for manufacturers who need to efficiently produce end-use parts and move to production-scale volumes. Also, new plug-in partners AlphaSTAR and Castor provide options for real-time part analysis and streamline integrated workflow.

The software is specifically designed to improve printed-part accuracy, reduce waste and shorten time to part. The software is available for customers using Stratasys printers based on Selective Absorption Fusion (SAF) and Fused Deposition Modeling (FDM) technologies.

The GrabCAD Print Pro software includes all the features of GrabCAD Print standard. However, its advanced capabilities create greater opportunities for large-scale additive manufacturing (AM) with better system controls, reduced production time and enhanced workflows.

Customers can achieve these benefits through unique features such as the warp Additive Model (WAM) which provides automatic warp correction to ensure part accuracy through 3D scanning and warp correction. The software also offers the ability to develop standardized manufacturing templates, enabling customers to prepare builds quickly and error-free.

It also features improved per-part cost estimation, with a significant reduction in time estimating multi-customer trays. Label generation includes unique coding, serialization and placement for Selective Absorption Fusion (SAF). The software also offers a 3D Array to arrange parts on the Z axis, enabling stacking of parts, to reduce build times and increase throughput.

“We are proud to deliver the best-in-class print preparation software package that reflects additive manufacturing’s expanding role on the factory floor,” says Rich Garrity, Stratasys chief industrial business officer. “Our customers are increasingly expanding 3D printing implementation beyond prototyping to end-use parts production at scale, where consistent quality and process efficiency are truly essential. This new next-generation software is designed to help them achieve their current and future business goals and allow them to significantly and rapidly scale up their additive manufacturing capabilities.”

For the first time, GrabCAD Print Pro also features third-party partner plug-ins, with initial plug-in partners to include AlphaSTAR and Castor. AlphaSTAR provides toolpath-driven analysis and quality assessment of print parameters and tool paths, as well as thermal process simulation to help improve design cycles and produce higher quality parts with less iteration. Castor’s decision-support software automatically analyzes thousands of parts at once to identify the best opportunities for additive manufacturing.

“The integration with GrabCAD Print Pro enables us to offer greater value to our customers,” says Omer Blaier, Castor co-founder and CEO. “Through this partnership, we enable more manufacturers to seamlessly incorporate Castor into their design and production platforms, thus identify additive manufacturing opportunities more easily. We’re excited to be part of the innovative Stratasys platform.”

- Join AM Associate Editor Fiona Lawler for a tour of the Stratasys production facility in Belton, Texas. This manufacturing site is growing to support various 3D printing applications for mass production in industries such as automotive and aerospace.

- Learn about Stratasys’ continued growth following its recent merger with Desktop Metal. The merger looks to deliver industrial polymer, metal, sand and ceramic solutions from design to mass production.

Related Content

3D Printed "Evolved Structures" for NASA Exoplanet Balloon Mission: The Cool Parts Show #61

Generative design creates stiff, lightweight brackets for EXCITE mission monitoring planets orbiting other stars. The Cool Parts Show visits Goddard Space Flight Center.

Read MoreCarnegie Mellon Helps Industry, Students Prepare for a Manufacturing Future with AM and AI

Work underway at the university’s Next Manufacturing Center and Manufacturing Futures Institute is helping industrial additive manufacturers achieve success today, while applying artificial intelligence, surrogate modeling and more to solve the problems of the future.

Read More7 Things We Saw at Formnext 2024 — Video Playlist

There were countless processes, applications and announcements at Formnext 2024. Here are seven standouts Peter Zelinski and Stephanie Hendrixson caught on film.

Read MoreSpherene Creates Metamaterial with Geometry Derived from Spheres

An algorithm developed by Spherene Inc. generates Adaptive Density Minimal Surfaces (ADMS) as a self-supporting infill strategy that can be used to reduce mass and manage material properties in 3D printed parts.

Read MoreRead Next

3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More