EOS Offers Production-Ready Shared Modules

Consisting of various hardware and software modules, EOS Shared Modules is said to simplify and parallelize workflow both upstream and downstream of the metal AM build process.

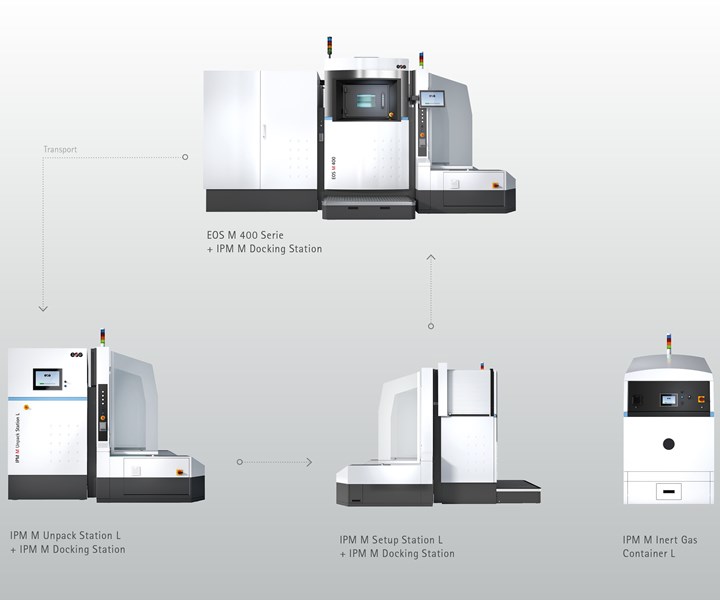

EOS’ Shared Modules integrate efficient additive manufacturing (AM) with systems of the EOS M 400 series. The various modules plus transport systems and control center software enable users to implement the equipping, unpacking, transporting and sieving activities parallel to the AM build process. Both manual and automated EOS Shared Modules set-ups are available for this purpose. This modularity gives companies flexibility to configure their production scenarios.

EOS Shared Modules Automated enables an automated additive manufacturing process.

The EOS Shared Modules components are set up individually and not as a combined unit, making them available for multiple 3D printing systems simultaneously. The EOSCONNECT ControlCenter software provides users with a continuous flow of key production parameters and part traceability by means of a digital twin. EOS Shared Modules is said to maximize machine uptime and boost productivity, leading to reduced part costs. The Shared Modules concept will eventually be offered for the EOS M 300 series as well, the company says.

When operating multiple 3D printing systems, automation and robotics make it possible to manufacture high-quality metal parts on an efficient, scalable, profitable basis, says EOS.

Dr. Hannes Gostner, Senior VP, Division Metal Systems at EOS, says: “Modularity is the big advantage for users, as they decide which degree of automation is ideal for their production. As demand grows, customers can increase the number of EOS M 400 or EOS M 400-4 systems and expand EOS Shared Modules accordingly.”

Related Content

-

Hybrid Additive Manufacturing Improves Debarking Knife Tip Strength and Production Efficiency

Nicholson Manufacturing chose the Mastercam APlus specialized add-on to unlock hybrid manufacturing for making its debarker knife tips, enabling it to add durable layers to the wear surfaces of the tips to make them more resilient while also making the production process more efficient.

-

Spherene Creates Metamaterial with Geometry Derived from Spheres

An algorithm developed by Spherene Inc. generates Adaptive Density Minimal Surfaces (ADMS) as a self-supporting infill strategy that can be used to reduce mass and manage material properties in 3D printed parts.

-

3MF File Format for Additive Manufacturing: More Than Geometry

The file format offers a less data-intensive way of recording part geometry, as well as details about build preparation, material, process and more.