I visited the Charlotte Advanced Technology Collaboration Hub (CATCH) in October 2022 to learn more about the work and scope of this facility. This video shows one example of the types of projects being done here: a topology optimized heat exchanger that captures energy from gas turbine exhaust, created at the request of the Department of Energy. Read on to learn more about this facility.

Opened in 2022, the CATCH facility in Charlotte, North Carolina, is described as an innovation center for advanced technology. But it would be a mistake to picture the Charlotte Advanced Technology Collaboration Hub as a shiny new showroom for technologies like additive manufacturing (AM). Instead, CATCH is a place where real problems are solved through advanced manufacturing technologies, of which additive manufacturing (AM) is first and foremost.

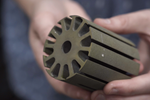

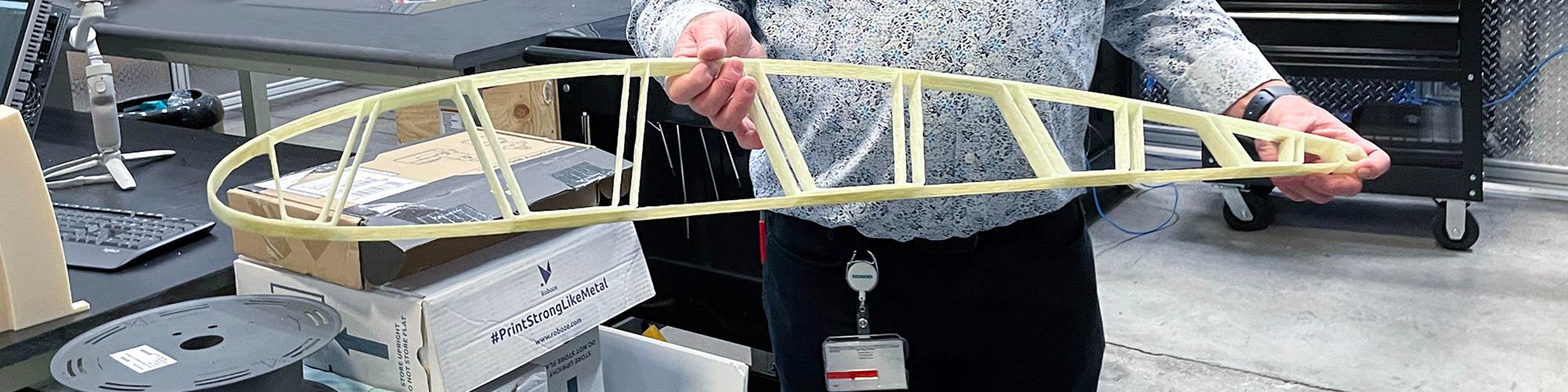

Tim Bell, Siemens AM business manager and the leader of CATCH, holds an airfoil 3D printed with continuous reinforcing fibers, part of a project to explore embedding heaters and lights into plane wings.

“Our focus is on industrializing AM,” says Tim Bell, additive manufacturing business manager for Siemens and head of CATCH when I visited. (Bell has since departed for Meld Manufacturing.) “If a project doesn’t meet that basic criteria, we don’t do that project.”

CATCH is one of five Siemens advanced manufacturing hubs around the world, but it is the only one that exists inside a Siemens Energy plant, sharing part of the footprint of the factory floor. On one side of a partition, huge gas turbine engines are being assembled, tested, repaired; on the other, a slew of 3D printers and rotating Siemens experts are working to solve problems ranging from reinventing existing part designs for 3D printing to engineering entire processes and business models for AM.

On one side of the partition at this Siemens plant, huge gas turbines are being assembled, tested and repaired. On the other, CATCH is working to solve next-generation problems through advanced manufacturing.

The Hub is staffed by a lean crew consisting of Bell, two full-time employees and usually a co-op or two. But it is not an island. CATCH is supported by various other Siemens entities and borrows Siemens resources and expertise when needed, whether for the creation of new APIs for the company’s software products, help with a PLC to control a 3D printing robot, or simulation expertise on a part in development. And in addition to the industrialization criteria, new projects also need to involve external collaborators whether they are industry customers, government agencies or additive suppliers.

“The biggest hurdle to AM is change management,” Bell says. “How do you get people to think AM?” Collaboration is a compelling means of facilitating that change, while also helping to ensure the success of projects. The “Collaboration” portion of CATCH is core to its mission and the work being done here.

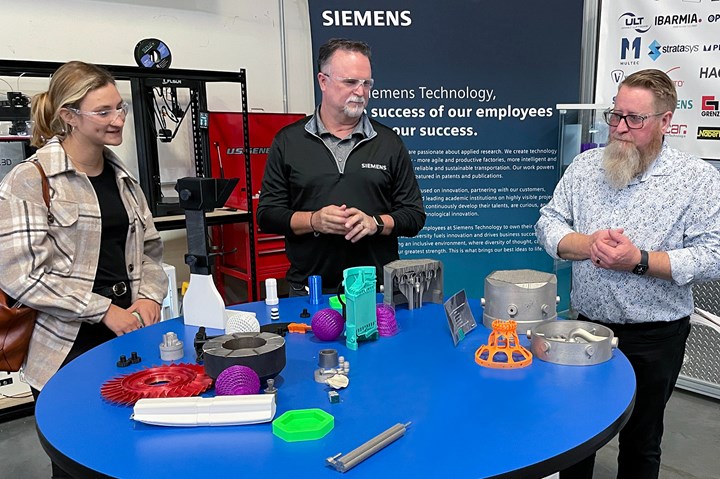

Parts spread across the table give some sense of the diversity of work being done at CATCH. As Bell says, “We don’t need someone to connect with all of these parts, but we need them to find the thing here that speaks to them.” (Left to right: Sarah Rubino, technical marketing for Siemens Digital Industries; Rich Stephenson, AM business development; and Tim Bell.)

But CATCH should also be understood by what it is not: a production facility. Bell is clear that the Charlotte hub is not meant for scale production or commercialization of any of the projects undertaken here. Not even the 3D printers are constant; all of the CATCH equipment is leased (funded through Siemens Financial Services), and no machine will stay for more than three years. Bell jokes that the facility’s unofficial motto is “catch and release” for the way that machines will come and go, but the metaphor also applies for the way that work moves through: Once a project is complete, it passes back to the partner or the customer.

(In cases where Siemens Energy is the customer, that could mean passing a project from CATCH down to the company’s Innovation Center in Orlando for production. Learn much more about the company’s additive manufacturing strategy enabled by the Florida facility in this article.)

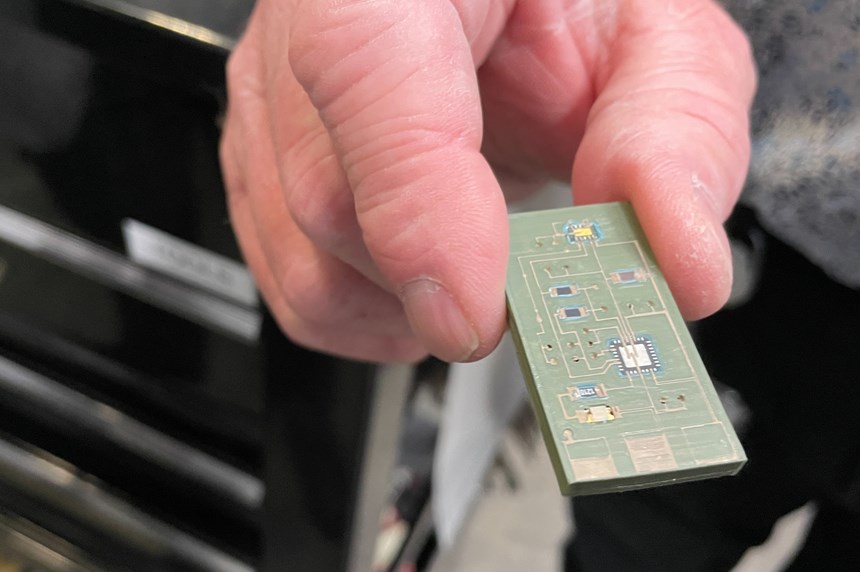

What types of projects are being done at CATCH? The work is as varied as manufacturing itself, but the examples that I saw or learned about on site included assisting a machine builder in advancing the design and UX of its 3D printer; embedding lighting and thermocouples into an airfoil made with continuous-fiber 3D printing (pictured near the beginning of this story); collaborating with CATCH’s Siemens Energy neighbors to develop 3D printable alternatives to turbine components such as exhaust pipes and consumable baskets; exploring 3D printed nanocircuits for wearable electronics; and developing an automated repair cell that will use a robot to laser-scan parts, cut away damaged portions, and apply additional material through 3D printing to build the part back. Some of this work is pictured in the slideshow below:

Projects at CATCH

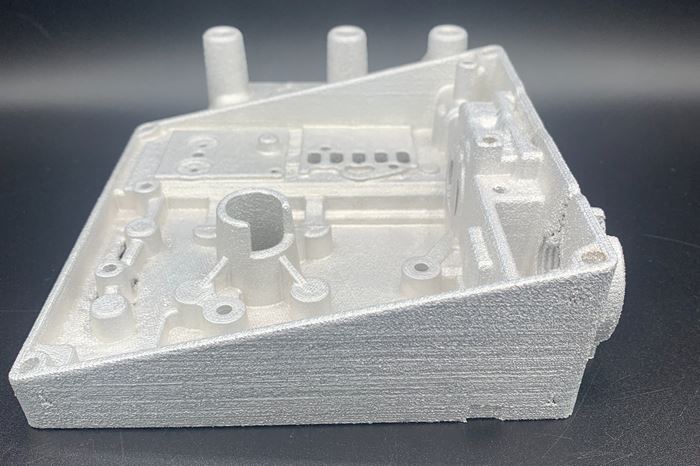

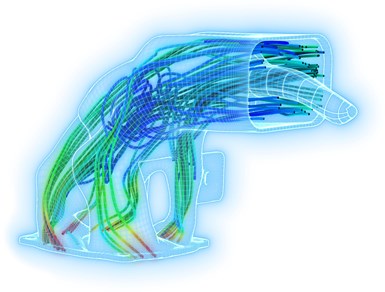

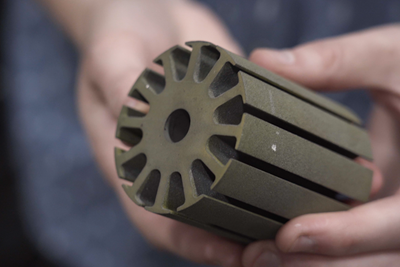

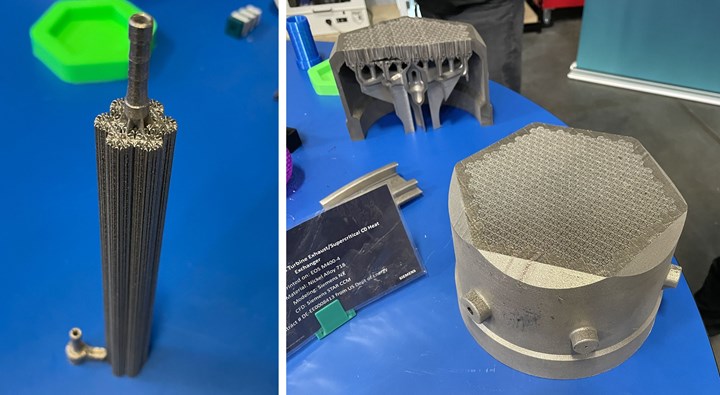

Many of the projects are understandably secretive, but a recent example for the Department of Energy is pictured below and featured in the video above. In looking for ways to leverage existing equipment in new ways, the DOE identified exhaust from gas turbines as an untapped source of power. CATCH developed, 3D printed and tested a heat exchanger designed to sit on the turbine exhaust and capture its heat to generate additional power. The heat exchanger is topology optimized for this role with a snowflake pattern repeating throughout its volume. It was 3D printed from 718 nickel alloy on an EOS M400-4 in two halves that are stacked and joined together. The part has been tested successfully with simulated gas turbine exhaust and steam; helium is next.

The piece on the left shows the snowflake geometry that repeats throughout the heat exchanger on the right. The component pictured here is actually half of the exchanger — the final product joins two of these pieces.

But underlying its impressive physical appearance, the final part also reflects a great deal of computational fluid dynamics (CFD) simulation through Star CCM+, which was used to evaluate the geometry before proceeding to print the part. In testing, this heat exchanger has proven to be within 5% of its simulated efficiency — a win for Siemens’ software iteration as well as the efficiency of gas turbines. This is the type of mutually beneficial development for which CATCH was created — an instance where Siemens, CATCH and the DOE all gained understanding that will drive the heat exchanger concept forward, along with insights into simulation for additive manufacturing.

“Our job is to get additive one step closer to being mainstream,” Bell says. A handful of projects have already “graduated” out of CATCH, and there are more to come.

Related Content

MC Machinery’s Wire-Laser Metal 3D Printer for Efficient, Versatile Processing

The printer applications include rapid prototyping, mold and die, one-offs, short runs, mass manufacturing, maintenance, repair, tooling and more.

Read MoreAccufacture Develops Alchemist 1 Robotic AM Cell Engineered With Meltio’s Wire-Laser Metal 3D printing Technology

This all-in-one additive manufacturing robotic work cell was engineered for seamless integration and rapid deployment for the safe and reliable manufacture and repair of metal parts.

Read MoreNikon Lasermeister Metal DED 3D Printer and Scanner Developed for Industrial Applications, Turbine Blade Repair

This technology gives manufacturers the ability to build onto existing parts with high precision and utilize a variety of materials, reducing lead times and minimizing postprocessing requirements.

Read MoreHybrid Additive Manufacturing Improves Debarking Knife Tip Strength and Production Efficiency

Nicholson Manufacturing chose the Mastercam APlus specialized add-on to unlock hybrid manufacturing for making its debarker knife tips, enabling it to add durable layers to the wear surfaces of the tips to make them more resilient while also making the production process more efficient.

Read MoreRead Next

How Siemens Energy Applies Additive Manufacturing for Power Generation and More

At an applications center in Orlando, Florida, a small team of AM specialists is spanning industries by 3D printing parts to support both Siemens Energy power generation systems and external customers.

Read MoreAM Will Change Power Generation, But Needs To Prove Itself First

In gas turbines and in nuclear power, Oak Ridge National Laboratory is working with major manufacturers to validate metal 3D printing for conventional parts as a prelude to developing the unconventional ones.

Read More3D Printing Rotors for Electric Motors (Video)

Oak Ridge National Laboratory describes research into applying additive manufacturing to replace windings in DC motors.

Read More

.jpg;width=70;height=70;mode=crop)