Authentise Flows Workflow Software Features Expanded Capabilities

The data-driven engineering and manufacturing workflow management suite is available in two versions — one for additive manufacturing and the other for nonadditive applications.

Share

Read Next

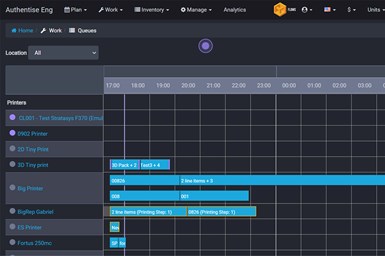

Authentise Flows and FlowsAM offer tools that stretch beyond the capabilities of a traditional manufacturing execution system Photo Credit: Authentise

Authentise, a provider of data-driven engineering and manufacturing workflow tools, has rebranded its workflow management suite for both additive manufacturing (AM) and nonadditive applications as its Flows and FlowsAM. With this release, Authentise is announcing general availability of FlowsAM for operations primarily centered around additive manufacturing, and Flows for those that are not.

Formerly known as the advanced Manufacturing Execution System (aMES), Flows incorporates many tools that stretch beyond the capabilities of a traditional manufacturing execution system, including real-time quoting, machine-data driven status updates, material genealogy, supplier management and more. These features are already used to manage postprocessing such as heat treatment, machining and more.

Flows and FlowsAM are based on the building of data-driven solutions for some of the world’s most agile operations, including Boeing, Danfoss, Ricoh and more. According to the company, Boeing’s time studies claimed that the system delivers up to 94% time savings and a 3 times ROI within eight months.

“We have long sought to use our experience in the additive sector to fuel digital manufacturing as a whole,” says Andre Wegner, Authentise CEO. “Additive has key advantages that make it a fertile sandbox, such as more data, less legacy and focus on lot size 1. That ability to manage agile operations is increasingly in demand as the world moves to address recent supply chain failures. That is why we’ve chosen this point to release Flows and FlowsAM.”

Keith Perrin, vice president of Agile Manufacturing at Authentise and formerly an executive managing Hexagon Nexus, Autodesk Fusion360 and Siemens Teamcenter has a unique perspective on the software suite. “Since I joined the team 8 months ago it’s become increasingly clear that Authentise has a ‘special sauce’ when it comes to handling production operations that require a high degree of flexibility. I know from experience that this is a big gap in the market, now more than ever,” Perrin says. “Authentise’s ability to integrate machine data, third-party software tools and human operations into a contextual process is critical to meeting that need. The success we’ve seen with some of the world’s most advanced agile engineering operations speak for themselves. I’m excited to bring this capability to other enterprises looking to deliver more flexible engineering, production and supply chains.”

Authentise FlowsAM is available today, while Authentise Flows will be generally available in 2023. An early adopter program is now open for customers with a particular interest in driving agile operations into their engineering and manufacturing operations, and realizing near triple-digit productivity improvements.

- Learn about the Authentise platform for organizing and sharing digital designs which helps users develop additive manufacturing projects and securely share those designs with production facilities.

- Read about the Authentise acquisition of Elements which gives the company more data-driven capabilities to provide pragmatic flexibility for solving manufacturing supply chain challenges.

Related Content

-

Implicit Modeling for Additive Manufacturing

Some software tools now use this modeling strategy as opposed to explicit methods of representing geometry. Here’s how it works, and why it matters for additive manufacturing.

-

Overcoming the Bottleneck to Customized Manufacturing: Quoting

Spokbee’s software-as-a-service platform is shaving months off of the quoting and pricing process for 3D printed and other types of configurable products.

-

User-Friendly Mass Spectrometry Tool to Enable AM

The Massbox is a technology designed to simplify mass spectrometry by bypassing the need to send samples to the lab for characterization and testing purposes. Exum Instruments’ debut tool is suitable for AM as it can assist with quality assurance, material characterization and failure analysis.