University of Maine Awarded $2.8 Million Grant for AM Wind Blade Research

Researchers will use the world's largest polymer 3D printer to develop recyclable wind blade molds that reduce lead times and costs.

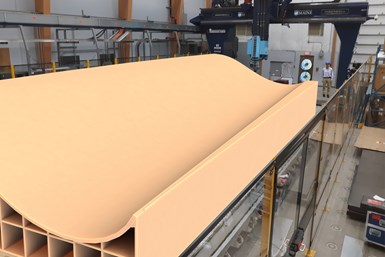

Rendering of a 3D printed wind blade mold segment.

The University of Maine (UMaine) Advanced Structures and Composites Center has been awarded $2.8 million from the U.S. Department of Energy Office of Energy Efficiency and Renewable Energy to develop a rapid, low-cost additive manufacturing (AM) solution for fabricating large, segmented wind blade molds. In addition, the center will collaborate on a $4 million award to the Oak Ridge National Laboratory (ORNL) to apply robotic deposition of continuous reinforcing fibers in wind blades.

Currently, innovation in large wind blade technology is a costly, time-intensive process. Molds and tooling for large blades can cost upward of $10 million, while the time to market of 16-20 months stifles innovation in this growing market.

UMaine researchers and students will apply their research knowledge in nanocellulose composites and wind blade testing to accelerate AM innovation in large wind blade development. Very large wind blade molds will be printed on the world’s largest polymer 3D printer located at the UMaine Composites Center using recyclable bio-based materials reinforced with wood.

“By combining cutting-edge 3D printing manufacturing with bio-based feedstocks, our team estimates that new blade development costs can be reduced by 25% to 50% and accelerated by at least six months,” says Habib Dagher, executive director of the Advanced Structures and Composites Center. Molds produced using these materials can be ground up and reused in other molds, making them a more sustainable solution.”

UMaine is a leader in cellulose nanofiber (CNF) technology, including development of nano- and micro-cellulose reinforced thermoplastic composites. These new bio-based materials promise mechanical properties similar to aluminum at lower fabricated costs. Carbon fiber reinforced ABS thermoplastic feedstocks, which are widely used in large-scale 3D printing, cost more than $5 per pound. By incorporating bio-based materials derived from wood, the cost of the feedstock can be reduced to less than $2 per pound.

Related Content

-

8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

-

Video: AM for Repair of Large Shafts

Wind power shafts that might once have been scrapped are now returned to service. See the robotic directed energy deposition (DED) and shaft preheating system developed by Ikergune, Izadi and Talens.

-

Aircraft Ducts 3D Printed in Composite Instead of Metal: The Cool Parts Show #68

Eaton’s new reinforced PEKK, tailored to aircraft applications, provides a cheaper and faster way to make ducts compared to formed aluminum.