The Size Limit on Powder-Bed Machines Has Now Been Overcome, Says GE

Innovations enabling the new ATLAS machine are scalable to even bigger parts than the component shown at Formnext.

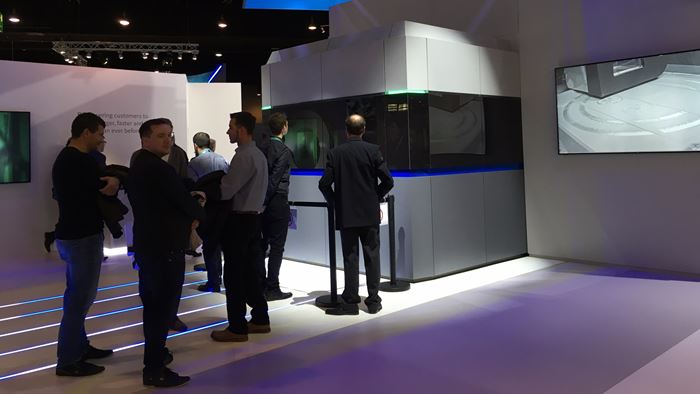

At the recent Formnext show, GE Additive introduced a beta machine resulting from its Project ATLAS, a Concept Laser machine offering a build envelope of 1.1 by 1.1 by 0.3 meter. Chris Panczyk, senior engineering section manager with GE Additive, was part of the international team (including GE personnel in North America and personnel with the GE-acquired Concepts Laser in Europe) responsible for developing this machine. Panczyk says those envelope dimensions are just a way station for now, not a stopping point. As a practical matter, because of the technology this machine employs, he says there is now no limit on the size a powder-bed AM machine might achieve.

In my conversation with him at Formnext, he was unwilling to detail this technology. The machine on-site at the show had ropes impeding attendees from getting close enough to study the mechanism of the machine’s operation. But the developments employed by this machine relate to applying the machine’s lasers over a large area, and containing the use of the powder to only the region needed for the dimensions of the part.

Part of the technique for using the lasers in a large area involves not forming all the part's cross-sectional area all at once within a given layer, but instead dividing each layer into sections. The result is a connection between sections that is cosmetically discernible in the part but not detrimental to integrity or precision. The part GE had on display showed a slight line between sections (a line more subtle than, say, the parting line in a molded part), but as evidence that consistency and precision are maintained across this line and between sections, Panczyk points to the STL file’s triangles that are also visible in the part’s surface. These can be seen crossing the section line without discontinuity.

At roughly 700 mm in diameter, the sample part shown used much of the available work envelope of the machine. That is, the machine is suited to this part. Panczyk says this suggests when and how machines like this one might be developed in the future. As even bigger metal parts are found to be significant candidates for powder-bed AM, machines will be engineered to accommodate their size.

Related Content

-

Copper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

-

The AM Ecosystem, User Journeys and More from Formnext Forum Austin: AM Radio #43

Sessions and conversations at the first U.S. Formnext event highlighted the complete additive manufacturing ecosystem, sustainability, the importance of customer education, AM user journeys and much more.

-

What We Found at Formnext 2023

New metal processes, new possibilities for existing processes, the next step for copper and more. Here is a summary drawing on all our reporting from November’s event.