Researchers Lay Groundwork for 3D Printing Electrical Machines

For more than a year, three partners have been focused on a research project that lays the groundwork for next-level electrical machines as they work to gain an in-depth understanding of the involved materials and technologies.

The research team says the design of crucial motor parts has a thorough impact on how the electrical currents interact with the magnetic field to create torque. Photo Credit: Ghent University

Additive Manufacturing for Electrical Machines (AM4EM) is a research project by Ghent University, KU Leuven and VITO for the application of 3D printing or additive manufacturing (AM) to improve the performance of electrical machines. The aim is to achieve more energy-efficient electrical motors such as stator or rotor cores.

Their focus is to imagine the perfect motor combining the best insulating and conductive materials in the best possible design — where the impact of the current is optimally converted into actual movement. The main challenge is to combine these conductive and insulating materials into complex multimaterial geometries. Researchers say this is a challenge because multimaterial 3D printing is basically still in its infancy. Hence, all materials, printing technologies and designs have to be thoroughly evaluated.

VITO is an independent research organization in the area of clean technology and sustainable development. More specifically, it has been researching 3D printing viscous powder-loaded pastes, which it says is an underexposed segment in AM. This paste printing with ceramics and metals is one of the technologies used in the project. The team says some important steps have already been realized. Micro-extrusion 3D printing of copper paste has led to printed parts without printing defects, a relative density of 95-99% and an electrical conductivity of 90-102% IACS. Researchers say this means it is possible to print pure copper with the properties needed for the applications at hand.

Positive results have also been achieved with the 3D printing of Fe-Si steel, which is needed for the motor core. The next step is to print multimaterial combinations for the magnetic core stacks, whereby a layer of ceramic insulator alternates with Fe-Si steel layers. Although initial results look positive, there are still related challenges such as uniform shrinkage of the material and warping of the layers.

KU Leuven is known in AM as the cradle of Materialise and Layerwise (now 3D Systems). In this project, it is focusing on fused filament fabrication (FFF) of metals and ceramics. Or rather it prints polymer filaments with a high content of metal or ceramic powder. The polymer in the filament is only needed to make the material printable and is removed after printing. Here, the challenge is only partially related to the 3D printing itself — debinding and sintering require careful analysis as well to determine the optimal parameters such as temperatures, solvents, extrusion width or speeds and more. KU Leuven’s efforts have resulted in relative density results above 95% for copper and 97.3% for ceramic, and even for combinations of both materials in one print.

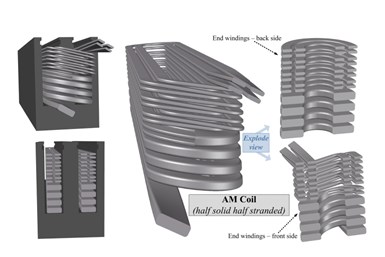

Ghent University has expertise in multiphysics models for electrical machines and is focused on the complexity of how currents actually flow through conducting materials, which requires in-depth simulation expertise. This is because the design of crucial motor parts has a thorough impact on how the electrical currents interact with the magnetic field to create torque. By consequence, the design details strongly determine how efficient the machine will ultimately be. Researchers says these smart designs can make quite a difference when it comes to the efficiency of the resulting magnetic flux.

These combined efforts on different printing techniques, design and material improvements may deliver innovative MM-AM processes that can be applied for sensors, radars, actuators, electrical machines and more. Ultimately, the AM4EM project targets an increase in energy efficiency by 5% (compared to small induction machines) and an increase in power density by 40%. The team says the fundamental research and development steps taken in the AM4EM project are essential in order to decrease the energy consumption of our society as a whole.

Related Content

Sustainable Furniture Company Model No. Maintains Product Focus with Switch from DIY to Industrial 3D Printers

The startup founded in 2018 has matured in its product offerings as well as its manufacturing equipment, moving from homegrown 3D printers to industrial large-format machines.

Read MoreEvaluating the Printability and Mechanical Properties of LFAM Regrind

A study conducted by SABIC and Local Motors identified potential for the reuse of scrap reinforced polymer from large-format additive manufacturing. As this method increases in popularity, sustainable practices for recycling excess materials is a burgeoning concern.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MoreNext-Gen Horse Trailers to Be Built With Robotic 3D Printing

Double D Trailers is currently developing a prototype horse trailer that will be made with large-format additive manufacturing. The technology brings potential benefits for labor, weight and design features to this subset of recreational vehicles.

Read MoreRead Next

Bike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More