Renishaw, Cobra Work to Optimize Design Process

Renishaw worked with Michigan-based Cobra Aero to improve the engine manufacturer’s design processes for aircraft and motorcycle engines.

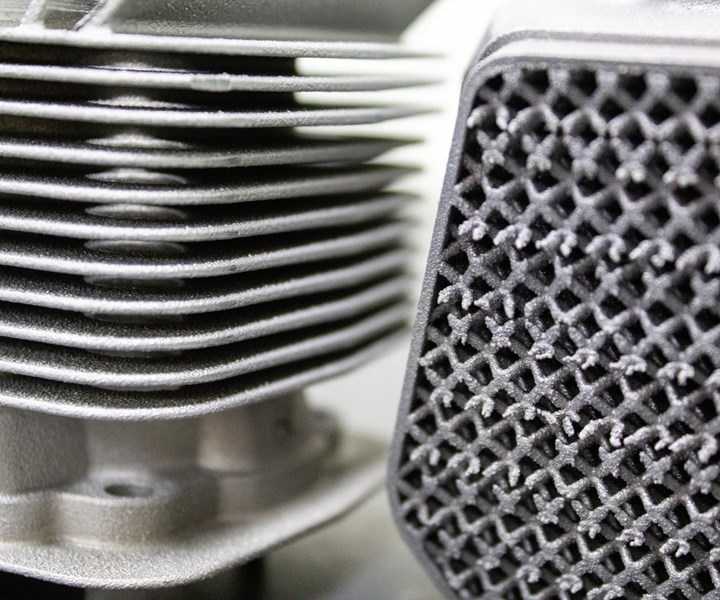

Renishaw worked with Michigan-based Cobra Aero to improve the engine manufacturer’s design processes for aircraft and motorcycle engines. They found that a single part with complex lattice structures works better than the original design.

Renishaw worked with Michigan-based Cobra Aero to improve the engine manufacturer’s design processes for aircraft and motorcycle engines. After completing the project with Renishaw, Cobra Aero invested in an AM 400 system to increase its in-house additive manufacturing (AM) capabilities.

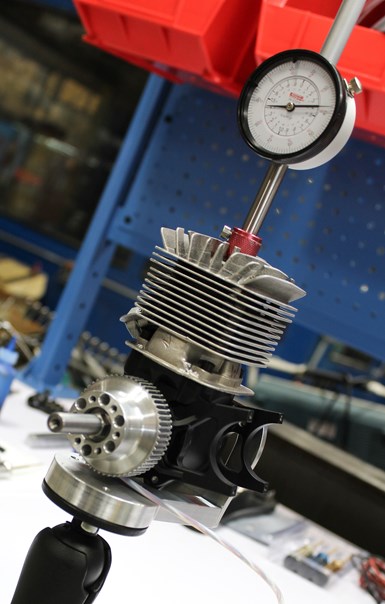

To optimize the design of its engine cylinders and to gain expertise in AM, Cobra Aero visited a Renishaw Additive Manufacturing Solutions Center. There they collaborated with Renishaw engineers to discover how AM could improve the design of a cylinder for an unmanned aerial vehicle (UAV).

Renishaw, Cobra Work on AM Engine Design Optimization

Sean Hilbert, president of Cobra Aero, says: “Investing in AM allows us to develop tools and new products for high value, small volume applications, speed up the manufacturing process and produce designs that would not be possible using conventional subtractive machining.”

According to Renishaw, Cobra Aero was able to produce a single part with complex lattice structures using Renishaw’s laser powder bed fusion technology that performs better than one made with conventional manufacturing techniques.

Related Content

-

New Zeda Additive Manufacturing Factory in Ohio Will Serve Medical, Military and Aerospace Production

Site providing laser powder bed fusion as well as machining and other postprocessing will open in late 2023, and will employ over 100. Chief technology officer Greg Morris sees economic and personnel advantages of serving different markets from a single AM facility.

-

Video: For 3D Printed Aircraft Structure, Machining Aids Fatigue Strength

Machining is a valuable complement to directed energy deposition, says Big Metal Additive. Topology-optimized aircraft parts illustrate the improvement in part performance from machining as the part is being built.

-

8 Cool Parts From Formnext 2024: The Cool Parts Show #78

End-use parts found at Formnext this year address various aspects of additive's advance, notably AM winning on cost against established processes.