MPI Launches AI Project to Create Material Reuse Management Tool for Metal 3D Printing

MPI is working with Additive Manufacturing Solutions and AMFG to create a versatile, commercial predictive material reuse management tool that will enable additive manufacturing to expand by introducing greater cost efficiencies.

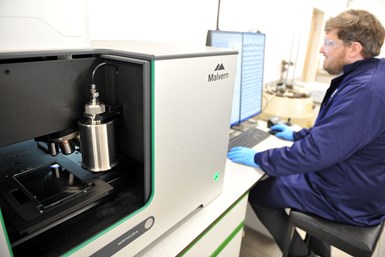

The SMART-APP is being developed to predict the quality change of the powder after each process and propose alternative process parameters on used powder to extend its life span with a minimal or an in-specification impact on product quality. Source: Materials Processing Institute

The Materials Processing Institute is leading a £600,000 research collaboration to develop a groundbreaking artificial intelligence (AI) tool capable of creating greater efficiencies within the additive manufacturing (AM) sector.

Working in partnership with Additive Manufacturing Solutions and AMFG, the collaboration aims to provide a versatile, commercial predictive material reuse management tool that will enable AM to expand by introducing greater cost efficiencies.

Known as SMART-APP, its goal is to enable world-class production of AM components, using laser powder bed fusion through the introduction of smart predictive models for resource efficiency and waste reduction.

SMART-APP aims to predict the quality change of the powder after each process and propose alternative process parameters on used powder to extend its life span with a minimal or an in-specification impact on product quality.

The project is funded by Innovate UK, part of UK Research and Innovation (UKRI), the UK’s innovation agency, which drives productivity and economic growth by supporting businesses to develop and realize the potential of new ideas.

One area of particular interest is the growth of metal AM which is not yet cost-effective due to a development gap in the level of powder waste and length of processing time.

The research will feature state-of-the-art materials characterization and mechanical testing, investigating shelf life and the processability envelope of environmentally affected common stainless steel, titanium and superalloy base feedstock. It will also examine methods of reclaiming the powders and the effect on the final product.

The resulting outputs will be fed into an advanced database linking powder input properties against AM part performance to provide a predictive tool that will be available for industry to use.

“SMART-APP is the next logical step to continue the work the Institute has already undertaken in powder characterization,” says Nick Parry, MPI industrial digitalization group manager.

Developing this artificial intelligence tool can help AM users create faster and cheaper ways of maximizing powder reuse, and aid the AM industry as a whole, especially those needing to maximize the operational effectiveness of their machines.

“This predictive tool will develop and enable world-class production of AM components, with smart solutions for resource efficiency and providing longer use of materials feedstock and reducing wastage,” Parry says.

AMS is gratified to have the support of Innovate UK to continue developing its portfolio of powder and AM process optimization capability. “This marks our first step toward a groundbreaking approach for dynamic materials management,” says Rob Higham, Additive Manufacturing Solutions CEO. “The potential of the AM process remains a potential in many people’s eyes. It could be realized with the development of a versatile and smart predictive tool for tracking powder quality after each reuse.”

AMFG, a software company providing MES and workflow automation for manufacturing, is part of the this initiative which aims to transform AM toward more resource-efficient methods. “SMART-APP aims to instil trust in the additive manufacturing realm by forecasting powder quality and recommending processes to restore desired powder properties for reuse,” says Alexander Grimmer, an AMFG technical consultant. “AMFG eagerly anticipates contributing to a cutting-edge material management system in this project, poised to deliver substantial environmental and economic benefits to the industry. This endeavour is set to expedite the widespread adoption of additive manufacturing.”

Related Content

Machine Tool Drawbar Made With Additive Manufacturing Saves DMG MORI 90% Lead Time and 67% CO2 Emission

A new production process for the multimetal drawbar replaces an outsourced plating step with directed energy deposition, performing this DED along with roughing, finishing and grinding on a single machine.

Read MoreHow 3D Printing Aids Sustainability for Semiconductor Equipment: The Cool Parts Show Bonus

Hittech worked with its customer to replace fully machined semiconductor trays with trays made via DED by Norsk Titanium. The result is dramatic savings in tool consumption and material waste.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreBMW Expands Use of Additive Manufacturing to Foster Production Innovations

The BMW Group is manufacturing many work aids and tools for its own production system using various 3D printing processes, with items such as tailor-made orthoses for employees, teaching and production aids, and large, weight-optimized robot grippers, which are used for such things as carbon fiber-reinforced polymer roofs and entire floor assemblies.

Read MoreRead Next

Postprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read More