Share

Read Next

For episode #72 of The Cool Parts Show, we visited Norsk Titanium to learn how directed energy deposition (DED) metal additive manufacturing makes a wing splice for General Atomics. While we were there, we learned about another, non-aerospace application as well. Machine builder Hittech was machining the precise, rigid carrier trays required for semiconductor production out of solid blocks of titanium, but the costs included 90% material waste and 30 or more spent cutting tools for every part. In search of a more sustainable solution it could present to its customer, Hittech found Norsk’s proprietary DED process, Rapid Plasma Deposition (RPD). Now, carrier trays for the Dutch company are manufactured through RPD at the Norsk facility in Plattsburgh, New York, where we filmed this episode. | This episode of The Cool Parts Show is sponsored by Carpenter Additive

The Cool Parts Show is a video series from Additive Manufacturing Media that explores the what, how and why of unusual 3D printed parts. Watch more here.

Have a cool part to share? Email us.

Related Resources

- Hittech Bihca

- More on Norsk Titanium and Rapid Plasma Deposition

- Our previous episode of General Atomics’ use of RPD to make flight-critical aircraft parts

Transcript

Peter Zelinski

We are at Norsk Titanium, Plattsburgh, New York. Production facility, additive manufacturing, using a process they invented called Rapid Plasma Deposition. They make components out of Ti64 mostly for the aircraft industry. We just filmed an episode here, this very detailed episode about this General Atomics wing splice part made through this process. Check it out. But while we were here, we discovered another part that has nothing to do with the aircraft industry.

Stephanie Hendrixson

That's right. The part we're looking at in this bonus episode is not for aerospace. This is for the semiconductor industry. This part is called a carrier tray. And its role is to hold a silicon wafer inside of a machine that performs photolithography. This is the process that creates the pattern of circuits on chips. So the thing about this tray is that it has to be able to move very rapidly inside of that machine. It faces something like 15 g’s of acceleration and deceleration. So it needs to be very lightweight as well as stable and rigid so that the wafer stays perfectly flat.

Peter Zelinski

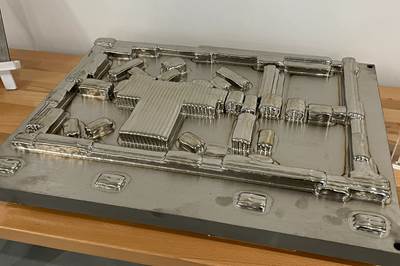

So this is the preform: what the tray looks like immediately after 3D printing. We'll get to more of that. Here is what the final tray looks like after machining. This tray was developed by Hittech Bihca, a maker of high end machinery, including equipment for semiconductor manufacturing. The tray needs to be solid titanium because of the stiffness required, because of that speed with which it moves through this machine. And previously, the starting point for this tray was a solid block of titanium.

Stephanie Hendrixson

Solid block of material, and they were machining away something like 90% of it in order to get the tray geometry that they needed. So to tell us more about this problem and how they solved it, here is Koen Mentink. He is the managing director of Hittech Bihca in the Netherlands.

Koen Mentink, Hittech Bihca

When the customer came in 2008, we started off with the titanium block, which was, like 700mm. So point seven meters, by half a meter, by, like, 11cm in height. And it was an original weight of 220 kilos of, of titanium and not, not the lowest or the cheapest version. And we think that our main product is chips or burrs, and we make like, 1.5m by 1.5m burst out of, of this block. So that's 90% of, of the original weight. The product our customer buys is only 10% of the original weight.

Peter Zelinski

Their main product was burrs, he said. Chips, the chips that are the byproduct of all of this machining. 90% of that original titanium block was lost to chips that were machined away, and that material wasn't the only waste. Koen hinted at some others. All that machining required a lot of coolant, oil based coolant. And then, in addition to all of the material waste, all of that machining used a lot of cutting tools as well. Cutting tools worn out through all of that cutting of metal. Here's Koen again.

Koen Mentink, Hittech Bihca

In the sense of how many tools we use in the part, it's typically 30 to 50 mills we use just to do the rough milling. But a cutter is like 70 to 100 euros and you have to imagine that you used it up in one hour, so it's very expensive to, to mill titanium. Our part is very thin. And when you take away a lot of, of material, typically the material bends. And so we also have to, put some steps in, to, to correct this, this bending of the material due to the stresses which are already in the material.

Stephanie Hendrixson

So that original machining process generated a lot of waste, both in terms of the material that was being cut away and in terms of all of the cutting tools that they were running through. But now, instead of starting from a solid block of material, they start with a 3D printed preform like this made here at Norsk Titanium, so there is still machining that is involved to get these preforms to their, to the finished product. but it is much less than previously. They're going through fewer cutting tools. And all of this gets at the reason that Hittech wanted to pursue additive manufacturing in the first place, which is sustainability.

Peter Zelinski

So Hittech did not yet have the customer’s buy-in to change the process, but they wanted to identify and develop and be able to propose the more sustainable process. They started exploring, tried a lot of different choices. So real quick they evaluated instead of titanium what about carbon fiber? Another very stiff material. The challenge there. Lots of fasteners go into the final tray attaching different components to it. So many fasteners that there needed to be essentially many different titanium inserts for threaded holes. It was just simpler to let the entire thing be titanium. titanium casting was another option that could have worked, but tooling is required there, and investment in tooling and the number of carrier trays that had to be produced couldn't cover that tooling investment. There's additive manufacturing through laser powder, bed fusion, established metal 3D printing process. But to make these parts through laser powder bed fusion, very expensive way to go. Cost prohibitive. But then they found additive manufacturing through Norsk Titanium’s process, which is a much more productive and cost effective additive process for these parts, in no small part because the build platform that the 3D printing layers on top of, that gets incorporated into the final tray.

Koen Mentink, Hittech Bihca

Currently we are around 20 to 30% cheaper but we are at the beginning of a learning curve. If you look at, at the base plate, which is in my background, currently we have I think triple as thick as we would use in the end product and also with the walls, we use a lot of meat. It's also a bit, we have to explain to Norsk in the aircraft business, it's very hard to to change something once you started with the process. But in our business, our customer really likes that we have cost savings throughout the years. so they are open for for changes. If it doesn't mean a risk for them and if it saves them money. Or gives them some other benefits.

Stephanie Hendrixson

So the specific additive manufacturing method used here is called Rapid Plasma Deposition. It was developed by Norsk Titanium. It uses two plasma torches to heat the material, and according to the company, it's capable of delivering forging quality parts.

Peter Zelinski

What Norsk Titanium is really good at is what the aircraft industry calls buy-to-fly ratio. How much material do you have to buy versus how much of that actually flies in the finished component on the aircraft? Norsk can reduce buy-to-fly ratio by delivering the part as this near net shape form that reduces the amount of machining required. The aircraft industry wants to reduce the amount of material that has to be wasted as chips. Hittech’s parts don't fly, but they have the same problem and the same solution works here as well. This near net shaped part, this preform reduces the amount of machining required, but there's still farther to go.

Koen Mentink, Hittech Bihca

Our customer sells machines which are in the millions, so I think, the most expensive machine is, is, as expensive as a Boeing 737 or, an Airbus. And they can be that expensive because they make that much output. But if they have a disruption in his output, let's say, because our part would break. Then they go get, of course, claims from their customers. so basically they are even more reluctant occasionally than, than aircraft business. So we needed to prove a lot. Now we are in a, in a situation where we don't have to do it anymore. But in the beginning, we have to measure a lot on the part, like ultrasonic testing, CT scans and things like that. But currently, I think we have them, at a level where they trust the material at least as good as, as the former process with the full block.

Stephanie Hendrixson

So Hittech saw that switching to 3D printing would allow them to deliver the part more easily. It would provide those cost savings to the customer, allow for design changes, but they still had to convince the customer. These trays go into very expensive machines that can cost as much as an airplane. And any downtime is a really big deal. So the customer had to be sure that the 3D printed carrier trays would perform as well as the conventional ones.

Peter Zelinski

Thank you, Norsk Titanium, for allowing us to film here in this Plattsburgh, New York production facility. If you haven't seen it yet, check out our episode on how General Atomics is converting previously aluminum parts of their aircraft to titanium.

Related Content

3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

Read More8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreHow Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

Read MoreDMG MORI: Build Plate “Pucks” Cut Postprocessing Time by 80%

For spinal implants and other small 3D printed parts made through laser powder bed fusion, separate clampable units resting within the build plate provide for easy transfer to a CNC lathe.

Read MoreRead Next

How Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

Read More3D Printed Titanium Replaces Aluminum for Unmanned Aircraft Wing Splice: The Cool Parts Show #72

Rapid Plasma Deposition produces the near-net-shape preform for a newly designed wing splice for remotely piloted aircraft from General Atomics. The Cool Parts Show visits Norsk Titanium, where this part is made.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read More