3D Systems Offers MJP 300W Printer, Wax Material for Advanced Jewelry Additive Manufacturing

The combination of the MJP 300W jewelry printer and VisiJet Wax Jewel Ruby enables jewelry designers to more efficiently achieve new designs with greater design freedom and improved surface finish.

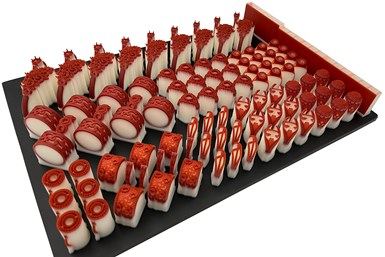

VisiJet Wax Jewel Ruby is a medium softness wax that offers an optimal combination of material flexibility properties and dimensional stability in high-temperature or humid environments. Delivers improved capability for the presetting of stones. Source: 3D Systems

3D Systems has developed the MJP 300W jewelry 3D printer and VisiJet Wax Jewel Ruby to improve additive manufacturing (AM) for jewelry production. The combination of this print platform and material enables producers of wax jewelry patterns — from high-volume manufacturers to custom jewelry makers — to more efficiently achieve new designs with greater design freedom and improved surface finish.

The MJP 300W is the most advanced and flexible of 3D Systems’ wax 3D printers, capable of addressing a variety of jewelry manufacturing workflows with enhanced productivity, efficiency, quality and design freedom. It offers improved speed, surface finish and reliability as well as two new build modes

Additionally, the VisiJet Wax Jewel Ruby material is a tough, temperature-stable pure wax that provides an optimal combination of flexible material properties and good dimensional stability in high-temperature environments. As a result, it is possible to maintain details of the most intricate jewelry designs during the molding process, reducing the likelihood of breakage or distortion to enable a flawless final piece.

The company says the use of 3D printing has the potential to play an increasingly important role in jewelry manufacturing, enabling efficient design and production of unique patterns that are not possible to produce with conventional methods. This enables mass customization by jewelry makers to meet consumers’ specific requirements in a rapidly changing marketplace.

Wax Printer Model Enhances Resolution, Boosts Efficiency

With the introduction of the MJP 300W, 3D Systems is unveiling two new print modes — QHD and UHD. The QHD mode enables more than 50% improved resolution in all axes (for example, 2,000 dpi in X, 1,800 dpi in Y and 2,900 dpi in Z) and 9.5-micrometer layer thickness compared to the previous generation wax 3D printer. This delivers premium quality surface finish, enabling designs to be produced with less finishing required. QHD also enables the printing of more complex designs where polishing is not practical or impossible.

The UHD mode offers 2 times faster print speed than XHD on the ProJet MJP 2500W Plus, which was introduced earlier in 2023. UHD offers significantly increased throughput and reduces the labor required for finishing and polishing. The availability of four print modes (QHD, UHD, XHD, ZHD) offers improved flexibility in build planning for both day and night shifts to match the level of speed, geometric complexity and surface quality required by all design styles.

The company has also made it easier to monitor a print job’s progress through the addition of an industrial stack light. This easy-to-see light can be conveniently positioned for the greatest visibility on the printer or an adjacent surface such as a desk or a cabinet. Additionally, reliability improvements through printhead and hardware modifications increase the uptime by decreasing replacement frequency and lower the cost of ownership.

100% Wax Material Delivers Optimized Mechanical Properties

3D Systems’ VisiJet Wax Jewel Ruby is the company’s most advanced material to deliver durable patterns that help create flawless final pieces. Patterns produced with VisiJet Wax Jewel Ruby have increased thermal stability compared to the recently introduced VisiJet Wax Jewel Red. Additionally, patterns created using VisiJet Wax Jewel Ruby exhibit durability that enables them to resist breaking through normal handling and maintain their dimensional stability through shipping. This latest material also enables presetting of stones to accelerate the production of the final piece.

“We were pleased to have early access to this material for our jewelry manufacturing applications,” says Shashidhar Kumar, partner at Shree Rapid Technologies. “Our experience has shown that is it very easy to handle, and delivers patterns with improved strength and flexibility, enabling us to provide higher quality, durable patterns to our customers. Additionally, the material is best suited for presetting stones, which is helping our customers improve efficiencies when creating pieces with intricate details."

Further expanding the extensive range of addressable designs, VisiJet Wax Jewel Ruby complements 3D Systems’ currently available wax materials — VisiJet Wax Jewel Red and VisiJet M2 Cast — which can also be used in conjunction with the MJP 300W.

“One of the greatest benefits of additive manufacturing is providing unlimited design freedom, which is especially important to unleash the creativity required by skilled artisans,” says Marty Johnson, vice president, product and technical fellow, 3D Systems. “With the introduction of the MJP 300W and our new VisiJet Wax Jewel Ruby material, we are providing producers of wax jewelry casting patterns with enhanced capabilities to improve productivity and processes that ensure reliability. 3D Systems’ full system integration of the materials, printer, print process and software — which is strengthened by our application expertise and global customer success team — is enabling our jewelry manufacturing customers to achieve new levels of innovation, quality and reliability.”

Related Content

Airless Basketball Shows Promise of 3D Printed Lattices: The Cool Parts Show Bonus

Successfully matching the performance of a standard basketball demonstrates the control possible over the mechanical properties of digital materials.

Read MorePossibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.

Read MoreThis Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

Read MoreFDA-Approved Spine Implant Made with PEEK: The Cool Parts Show #63

Curiteva now manufactures these cervical spine implants using an unusual 3D printing method: fused strand deposition. Learn how the process works and why it’s a good pairing with PEEK in this episode of The Cool Parts Show.

Read MoreRead Next

Alquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read More