HP, Materialise Integrate Technologies to Optimize AM Manufacturing Workflow

Working in combination with the Materialise CO-AM Software Platform, manufacturers can now link HP’s Multi Jet Fusion and Metal Jet technology to their existing production systems to optimize the additive manufacturing workflow from order entry to delivery.

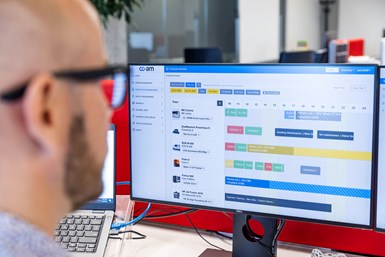

A seamless connectivity between HP AM technology and Materialise CO-AM enables users to create workflows that improve traceability, quality control and machine utilization. Source: Materialise

Materialise is collaborating with HP Inc. to integrate HP’s Multi Jet Fusion (MJF) and Metal Jet additive manufacturing (AM) technology into the Materialise CO-AM software platform. This collaboration enables manufacturing companies to raise the efficiency and quality of their 3D printing to match industrial requirements and use it for volume production of end parts.

“To scale additive manufacturing, the industry is in need of printers that are designed for high productivity coupled with an integrated end-to-end workflow solution — the partnership between HP and Materialise delivers this solution,” says Arvind Rangarajan, HP’s global head of Software and Data, HP Personalization and 3D Printing.

According to the companies, manufacturers recognize the unique benefits of AM, but face challenges as they onboard the technology. The speed of their 3D printing process may not hold up to volume production and they may have difficulties integrating the process with existing manufacturing technologies. To support these companies, HP delivers industrial 3D printing solutions that are manufacturing-ready.

In combination with the Materialise CO-AM Software Platform, manufacturers can link HP’s Multi Jet Fusion and Metal Jet technology to their existing production systems and optimize the AM workflow from order entry to delivery.

As an HP preferred partner, Materialise will provide the industry with an end-to-end manufacturing solution that is integrated with an additive technology which is designed for productivity and scale — the MJF and Metal Jet systems. As part of this partnership, HP will help customers identify meaningful use cases for the software platform, as well as showcase the solution at HP demo facilities and public events.

“Manufacturers are increasingly using 3D printing for end-use parts instead of solely in the prototyping and design phase,” says Bart Van der Schueren, Materialise CTO. “This partnership will help drive this shift by supporting more efficient, repeatable volume production.”

The seamless connectivity between HP AM technology and Materialise CO-AM enables users to create workflows that improve traceability, quality control and machine utilization. Optimized 3D print job management enables production leads to track planned and actual printer activities and optimize machine time.

To ensure continuous production, real-time machine monitoring provides operators and engineers with critical process data, including build status, material usage and machine sensor data. This data can be collected and stored in log files of 3D printed jobs to enhance traceability and quality control.

In addition to their 3D printers, Metal Jet users can connect process-relevant HP machinery to the CO-AM platform, such as powder management station, curing station and powder removal station. This integration enables Metal Jet users to streamline postprocessing of metal parts within the manufacturing process.

CO-AM includes Materialise’s leading data and build preparation capability from Magics, which connects to HP 3D printers via the HP Build Processor. Users benefit from a proven tool set to prepare their 3D printing jobs for all major AM technologies. Users can add workflow automation for repetitive tasks and use nesting to maximize the number of parts per job to increase machine utilization.

Additionally, CO-AM provides access to complementary solutions from Materialise and third parties, including CO-AM partner solutions for design automation, mass customization, automated labeling and various postprocessing technologies. CO-AM enables AM users to connect and manage technologies from different machine builders over one platform.

Related Content

3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

Read MoreSpherene Creates Metamaterial with Geometry Derived from Spheres

An algorithm developed by Spherene Inc. generates Adaptive Density Minimal Surfaces (ADMS) as a self-supporting infill strategy that can be used to reduce mass and manage material properties in 3D printed parts.

Read MoreUser-Friendly Mass Spectrometry Tool to Enable AM

The Massbox is a technology designed to simplify mass spectrometry by bypassing the need to send samples to the lab for characterization and testing purposes. Exum Instruments’ debut tool is suitable for AM as it can assist with quality assurance, material characterization and failure analysis.

Read MoreActivArmor Casts and Splints Are Shifting to Point-of-Care 3D Printing

ActivArmor offers individualized, 3D printed casts and splints for various diagnoses. The company is in the process of shifting to point-of-care printing and aims to promote positive healing outcomes and improved hygienics with customized support devices.

Read MoreRead Next

Postprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreHow Avid Product Development Creates Efficiencies in High-Mix, Low-Volume Additive Manufacturing

Contract manufacturer Avid Product Development (a Lubrizol company) has developed strategies to streamline part production through 3D printing so its engineering team can focus on development, design, assembly and other services.

Read MoreNew Equipment, Additive Manufacturing for Casting Replacement and AM's Next Phase at IMTS 2024: AM Radio #54

Additive manufacturing’s presence at IMTS – The International Manufacturing Technology Show revealed trends in technology as well as how 3D printing is being applied today and where it will be tomorrow. Peter Zelinski and I share observations from the show on this episode of AM Radio.

Read More