ExOne, SSI Collaborate to Drive Volume Production with Metal Binder Jetting

With ExOne 3D printers and SSI’s furnace and sintering capabilities, the parts manufacturer says it will offer components with increased complexity and size for volume production with no tooling in a variety of metals.

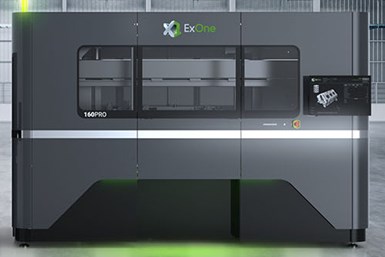

SSI will use the InnoventPro 3L for material and application development, with the X1 160Pro dedicated to volume production through a fully automated cell with continuous sintering and state-of-the-art furnace equipment. Photo Credit: ExOne

Wisconsin-based SSI Sintered Specialties, a supplier of high-performance metal parts, has purchased two metal binder jet 3D printers from ExOne, a global supplier of industrial sand and metal 3D printers using binder jetting technology.

SSI will use the InnoventPro 3L for material and application development, with the X1 160Pro dedicated to volume production through a fully automated cell with continuous sintering and state-of-the-art furnace equipment. The InnoventPro 3L metal binder jetting system features ExOne’s Triple Advanced Compaction Technology (ACT).

The two ExOne printers are slated for delivery in the first half of 2022 and will be located at the company’s headquarters in Janesville, Wisconsin. SSI says its 250,000-square-foot facility also houses the world’s largest installed capacity of high-temperature sintering furnaces — a process step which is core to metal binder jetting – and postprocessing technology to support volume production in metal binder jetting.

“The addition of metal binder jetting to SSI’s technology portfolio was the natural next step in providing our customers with the most advanced technology on the market to produce complex geometries in volume production,” says Paul Hauck, SSI Sintered Specialties COO. “Our expertise and lengthy heritage in high-temperature metallurgy processing is a perfect fit for binder jetting technology, and we are thrilled to be working with ExOne to offer our customers the future of metal 3D printing.”

SSI has over 40 years of powder metallurgy experience and metal 3D printing adds to the company’s existing capabilities in press and sinter powder metallurgy, and nontraditional metal injection molding. With ExOne’s 3D printers and SSI’s furnace and sintering capabilities, the parts manufacturer says it will offer components with increased complexity and size for volume production with no tooling in a variety of metals.

The investment in ExOne’s binder jet technology is just one of the steps in SSI’s business strategy to embrace additive manufacturing and bring new manufacturing solutions for volume production.

Related Content

-

What Is Neighborhood 91?

With its first building completely occupied, the N91 campus is on its way to becoming an end-to-end ecosystem for production additive manufacturing. Updates from the Pittsburgh initiative.

-

3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

-

Beehive Industries Is Going Big on Small-Scale Engines Made Through Additive Manufacturing

Backed by decades of experience in both aviation and additive, the company is now laser-focused on a single goal: developing, proving and scaling production of engines providing 5,000 lbs of thrust or less.