Part Removal Efficiency In a 600 mm Plus World

Clay Olson of EDM Performance Accessories discusses the difficulties and opportunities in cutting off parts from the build plates of large AM systems. Molybdenum wire EDM offers an effective solution to the challenge of large-part cutoff.

“Just cut it off.” Sounds simple, right? This process is not pretty, fancy or fun like the engineering, design and execution of creating a part through additive manufacturing (AM) in metal.

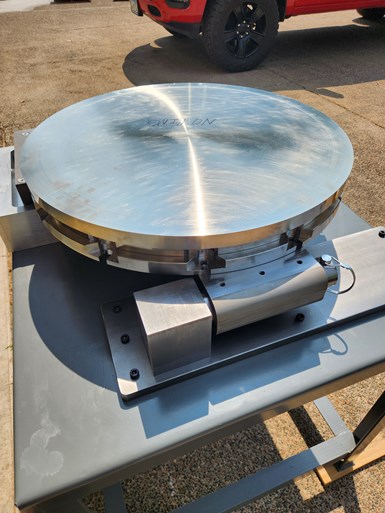

Depicted above is a large build plate flip fixture assisting in the removal of large, additively made parts via EDM.The size of the plate seen here is representative of large-format laser powder bed fusion 3D printers, and presents challenges for conventional wire EDM. Photo credit: EDM Performance Accessories

In the full cycle of direct metal laser sintering (DMLS) or laser powder bed fusion 3D printing, part removal or “cutoff” is the recurrently forgotten step; an afterthought and rightfully so. I mean, who cares how you get the part off the plate as long as it’s off?

Manufacturers tend to focus on more urgent matters once a build is complete, such as heat treating, powder removal, inspection, density testing and postprocessing. Why is part removal overlooked? A cutoff doesn’t need to be extremely accurate, as the part almost always undergoes additional postprocessing. However, this quiet, overlooked afterthought could be a silent cost killer in the making.

The Size Challenge

Metal AM saw a substantial shift in 2021 with the advent of platforms with build plates measuring 600 mm or larger from Velo3D, SLM Solutions and GE Additive’s Concept Laser.

While these printers have proven to be game changers in terms of their capacity to print part sizes and quantities never before seen, they are quickly revealing shortcomings in the manufacturing process. Past jumps from 250 mm to 300 or 400 mm did not cause quite the same commotion despite the fact they shared similar postprocessing methods.

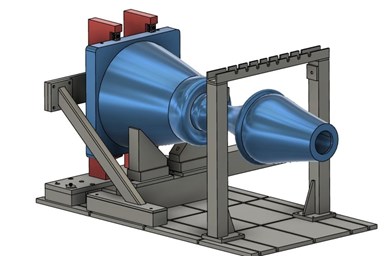

The digital model depicts how the fixturing support device works to catch large parts once removed from the build plate post-print. This particular example is a support combination, as the part is supported by wedges underneath and overhead support from above. Photo credit: EDM Performance Accessories

The shift to platforms 600 mm and larger enables part weights and sizes that few additive manufacturers are able to safely and effectively handle. Removing these large parts from the build plate is a major challenge many providers face now.

How do you take a platform and a part of this magnitude and ensure it is safely handled, fixtured and affordably removed from its build plate? All of these factors must be considered in tandem with accuracy, to avoid scrapping a costly part.

The Removal Process Is Not Set In Stone

The first thing to consider is the need for establishing a cutting method as well as a machine that are actually capable of handling 600 mm platforms. Hand tools and cutoff wheels will not prevail in the ever-evolving additive world. Wire EDM or bandsaws will be the only options with the capability to complete the job.

Traditional bandsaws offer low purchase and operating costs, but at the expense of inaccurate cuts. In other words, bandsaws get the job done quick and dirty. This process is fairly effective on builds up to 300 mm, some even on 400 mm applications. However, the drawback of a bandsaw is magnified at 600 mm.

The cost of a saw this large and the fixturing required to hold parts as well as plates will make a bandsaw no longer the low-cost option users have been familiar with. Large saws are costly and have higher maintenance expenses. The issues with cutting hardened materials like titanium and Inconel with a saw grow substantially at 600 mm.

For instance, there is the increased risk of a blade wandering. This can lead to scrapping a part, the build plate or both. While bandsaws remain an available option, they are far from the ideal solution.

Now, let’s turn to the world of electrical discharge machining (EDM). This process utilizes a small wire to cut through even the hardest materials with incredible accuracy. The challenge for EDM as it is usually applied comes with the 600 mm or taller cut heights. These are a death sentence for traditional brass EDM wire.

Machines using this wire require a submerged work tank and optimal flushing conditions to achieve an acceptable and reliable cut speed. The enclosed, submerged tank brings challenges with loading and holding of massive plates and parts within them. Brass wire EDM machines able to handle significant size are costly. Add on the cutting costs of $12 or more per hour, the chance of wire breaks and cutting delays, and brass wire EDM hits a similar roadblock as seen with the bandsaws.

The New Frontier

As plate size continues to grow, it becomes more and more difficult for manufacturers to handle. Fortunately, there is an emerging third option for EDM technology and it has the potential to be a game changer for postprocessing.

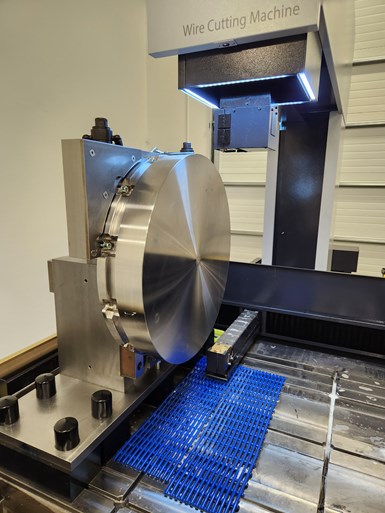

This open-air wire EDM machine does not require a submerged work tank to perform cutting. While the image above depicts a smaller build plate and part, this technology is promising for handling large build plates both safely and effectively. Photo credit: EDM Performance Accessories.

Molybdenum EDM, also referred to as “fast wire” EDM, has been growing in use in the United States. The technology is focused on the metal AM market for additive cut offs. Unlike brass EDM, these machines exclusively use molybdenum wire to reciprocate through the machines at high speeds.

This technology does not require optimal flushing, a submerged tank or the highly complicated hardware found in brass EDM. Additionally, it operates for well under $2 per hour.

The technology is complementary with AM. EDM Performance Accessories introduced its HB Series Moly Cut EDM in 2016. While this technology has been applied to part removal with plates up to 500 mm, the emerging 600-mm and larger plates are where we are finding the biggest advantages for efficacy and safe handling of these larger plates and workpieces.

Molybdenum EDM is unaffected by tall or interrupted cuts found in most 600 mm cutoffs. The two main factors here are material type and thickness, which simplify the cut technology selection for operators. The machines utilize high wire speeds to create a flushing effect though the cut gap. The wire runs both up and down for 30 to 40 hours of cutting time on the same piece of wire.

Reusing the EDM wire for this time period and doing so on a simplified EDM machine results in cutting costs below $2 per hour, while cycle time increases to about two to three times that of brass EDM in many cases. The advantage for 600 mm printers is a potential 80% reduction in postprocessing costs and hours (perhaps days) of time savings on every build plate.

Handling and Safety Measures

Our largest model, HB1200, was introduced specifically for handling larger AM build platforms. What sets this machine apart is its massive, open work area and weight handling ability. The machine bed is accessible from all four sides and virtually open overhead (besides the small upper head column). This enables operators to utilize the booth overhead for crane or fork truck plate loading. Four-sided access without a submerged tank is beneficial for easier and safer plate loading. This facilitates a secure work environment for operators while tending to large, heavy plates.

The above image depicts the installation of an HB1200 machine at Keselowski Advanced Manufacturing. The fixture set up will support large build plates and enable proper handling for part removal for large-format metal additive. Photo credit: Keselowski Advanced Manufacturing

When fixturing parts, it’s not uncommon for the fixturing alone to weigh in at over 600 pounds to accommodate the plates. When handling parts and plates of 600 by 600 mm and over 1.2 meter tall, having enough space and weight capacity to build proper fixturing is critical.

Unfortunately, no machine offers a one-size-fits-all answer. Different plate systems, from the round Velo3D plates to square and rectangular plates of other manufactures, have different fixturing needs. Plus, the work might be one large rocket component or 200 smaller production parts to catch.

For this reason, we also build custom fixtures, and have developed a list of cutoff considerations for use in the design process. Considerations include:

- Does the build plate require a sub-fixture? Most square plates are easier to handle than a round plate, which almost always need a sub-fixture plate to allow for easier handling and moving.

- How am I going to lift and move heavy plates and parts? A forklift or overhead crane? Is there enough room to maneuver with a forklift?

- How will I safely maneuver a plate from horizontal to vertical without endangering an operator or the part itself? Is it best to flip the part in the machine or on a staging table?

- Once horizontal, how can I secure the part in the machine? How strong does this need to be based on part size and how quickly and easily can an operator secure it? Can an operator safely access the space around the fixture for alignment and securing purposes?

- During cut off, what will support the part for catching? Is it best to use supports from below or supports from above (like a harness)?

Supporting Large-Format 3D Printing

600-mm build plates are groundbreaking. They allow manufacturers to re-imagine what is possible with part design and fabrication.

Yet when scale is increased, something as simple as part and plate separation can quickly become a challenge. The advance in printing equipment calls for progress in support equipment. Molybdenum EDM is the cutoff option able to make working with these large metal AM builds easier, safer and more cost-effective.

Related Content

At General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read MoreVulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

Read More3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

Read MoreWhat Is Neighborhood 91?

With its first building completely occupied, the N91 campus is on its way to becoming an end-to-end ecosystem for production additive manufacturing. Updates from the Pittsburgh initiative.

Read MoreRead Next

Formlabs Part Removal Mechanism Enables Lights-Out Production

A build platform overcoming the need for manual part removal enables automated part handling, and therefore continuous production from one build cycle to the next.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More