News

Grabcad Print Pro Software Helps Improve Part Accuracy, Workflow

The software features new plug-in partners AlphaSTAR and Castor, providing options for real-time part analysis and streamline integrated workflow.

Read MoreVelo3D Qualifies Aluminum Alloy to Support Formula 1 Customers

Aluminum alloy supports Formula 1 customers by enabling the production of parts requiring high thermal conductivity and durability, and is available to print in both 50 and 100 micron layers.

Read MoreMaterialise Opens Medical 3D Printing Facility

At the new facility in Plymouth, Michigan, Materialise specializes in the 3D printing of personalized titanium cranio-maxillofacial (CMF) implants for more patient-specific care.

Read MoreEOS, nTop Create File Capability to Limit Design Data Bottlenecks

EOS and nTop have created a new nTop Implicit File that can result in up to 99% smaller file sizes, 500 times faster file generation and 60% faster load time, making it more readily available to additive manufacturing build preparation software for manufacturing.

Read MoreDyndrite Joins NMIS to Advance 3D Metal Manufacturing Research

Dyndrite has joined NMIS to help develop build recipes and shareable knowledge in materials process development across all major laser powder bed fusion OEM file formats.

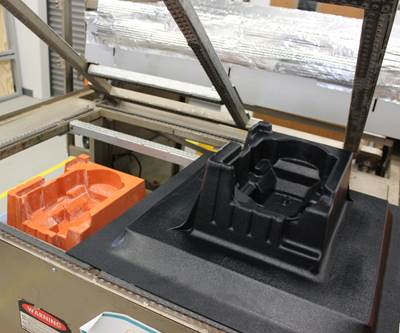

Read MoreCatalysis Additive Tooling Licenses 3D Printed Tooling Technology in Europe

The innoMold company will spearhead the tool manufacturing operating under the name “Catalysis Additive Tooling GmbH,” beginning operations in October 2023.

Read More3D Systems Develops Materials, Printer Platform for Improved Digital Dentistry

3D Systems is strengthening its digital dentistry portfolio with new materials, NextDent Base and NextDent Cast, and a new printing platform, the NextDent LCD1.

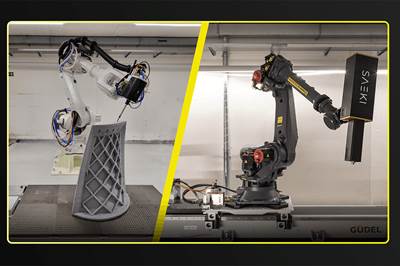

Read MoreSaeki Robots Manufacture Large Parts for Lights-Out Production

Saeki says it is building flexible factories of the future by leveraging digital manufacturing and robotics, providing an end-to-end automation solution in 24 hours with manufacturing large parts performed by robots.

Read MoreAddUp Adds Constellium’s Aheadd CP1 Aluminum Alloy to Material Portfolio

The Aheadd CP1 aluminum alloy was developed by Constellium for the needs of additive manufacturing by laser powder bed fusion specifically for high-performance and lightweight applications.

Read MoreStudy Gives High Marks to Dimensionic’s Density Determination Platform

Dimensionics Density’s automated density determination solution receives high marks in Fraunhofer Institute’s independent study of additive manufacturing density determination technologies.

Read More