Combining Metal and Polymer for Better 3D Printed Tools

Applications prone to wear call for more durable tooling than 3D printed polymer alone, but full metal is not always necessary.

Share

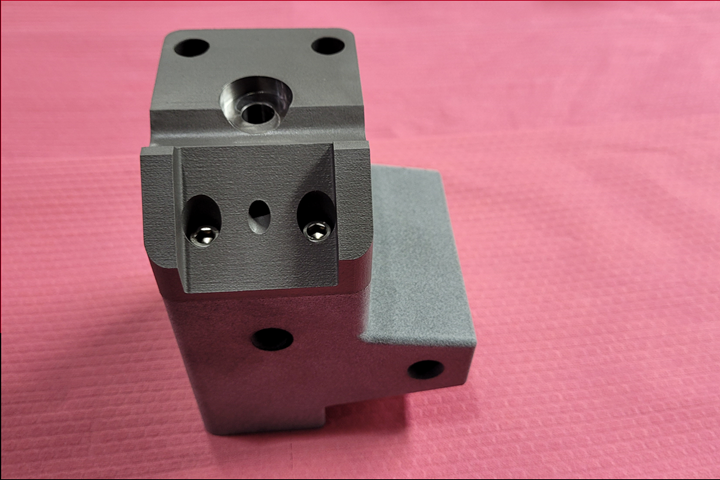

This inspection assembly fixture — a hybrid of metal and polymer additive technologies — features 3D printed maraging steel (top black components with bolts produced via DMLS) and PA12 (lower gray component produced via MJF or SLS). Use of both additive technologies helped Linear AMS reduce mass, cost and print time while producing a usable assembly aid much faster than conventionally machined metal would allow. Photo Credit: Linear AMS, a Shapeways Co.

When Linear AMS (Livonia, Michigan) first began using metal 3D printing, its initial focus was on designing and printing conformally cooled/heated mold components like slides, lifters and inserts for its own injection molds and later, those of molding and mold building customers. The company later added polymer AM capabilities for part prototyping. Subsequently, Linear began printing gages, fixtures and assembly aids for its own manufacturing operations, including injection molding, and later for customer needs. By 2023, the 20-year-old moldmaker was equipped with metal 3D printers from EOS, Colibrium and Desktop Metal, plus polymer 3D printers from HP and EOS.

Speaking with CompositesWorld in 2023, Linear AMS shared how the company was succeeding with additive manufacturing of end-of-arm tooling (EOAT) and inspection fixtures, often through a combination of materials:

“Most of our EOAT and fixtures combine both metal and polymer AM component for structural integrity, to address wear items and to seat assembly fixtures,” explained David Myers, then-senior business development executive at Linear AMS. Myers described one example, “an inspection assembly fixture that uses a combination of PA12 and maraging steel, as these items can get abused. This enables us to provide a turnkey solution for our customer.”

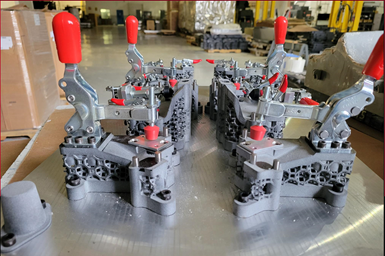

Taking advantage of the ability of AM to produce lattice structures — which not only reduce mass, material use and cost and printing time, but also increase structural integrity, — Linear AMS applied the technique to 3D print inspection fixtures like those shown above. The gray lattice material is PA12 produced on an MJF or SLS printer; the red handles/clamps and bolts are off-the-shelf purchased components; and the silver base plate is conventionally machined aluminum. Photo Credit: Linear AMS, a Shapeways Co.

Typical tools the team was printed at the time included press-based robotics for part removal or for insertion of hardware into a tool prior to molding, as well as hybrid gages and fixtures.

“There are times when you’ve tried everything you can from a processing and tooling standpoint and you still have warpage,” Myers continued. “In cases like that, we use our AM technology and knowledge of thermoplastic materials, injection molding and Kentucky windage to design cooling fixtures that counteract warpage and deliver dimensionally accurate parts.”

He added that initially it was design flexibility and speed of production that encouraged the team to try producing manufacturing aids additively. “The first time we tried this, not everything worked perfectly out of the gate, but the beauty of digitization is how fast you can fine-tune a design and how quickly you can build a digital catalogue that can be used to tweak future designs,” Myers said. “In fact, we’ll often design a print build to include two different design revisions at the same time, since we have the real estate in the build chambers to add more parts, and this makes finalizing the design quicker and easier. There are so many advantages to getting to market faster.”

Myers noted that molding aids were in demand not from moldmakers, but rather molders themselves. “Typically, moldmakers aren’t as concerned with downstream processes, but it’s the molders who reap the benefits,” Myers said. “Often, because they purchased a mold with conformal cooling, now they can cycle parts much faster, which means that the downstream process isn’t keeping up with the upstream portion, so suddenly molders are asking how they can do this task or that faster.”

What benefits does AM technologies bring? “There are the obvious things like design flexibility, speed, no scrap and lower cost,” Myers added. “However, there’s also the ability to print lattice structures that not only are lighter and faster to print but also improve structural integrity. Also, what we’ve seen, especially on the metals side, is that AM manufacturing aids will go head to head with conventionally produced parts in terms of life expectancy and damage tolerance. You get all of that and don’t have to wait 6 weeks to have a component produced conventionally — that’s a win-win.”

More From This Author

Peggy Malnati is a Detroit-based contributing writer for CompositesWorld magazine, for which she primarily reports on automotive and ground transportation. SUBSCRIBE HERE

Related Content

Large-Format “Cold” 3D Printing With Polypropylene and Polyethylene

Israeli startup Largix has developed a production solution that can 3D print PP and PE without melting them. Its first test? Custom tanks for chemical storage.

Read MoreDMG MORI: Build Plate “Pucks” Cut Postprocessing Time by 80%

For spinal implants and other small 3D printed parts made through laser powder bed fusion, separate clampable units resting within the build plate provide for easy transfer to a CNC lathe.

Read MoreVideo: Construction 3D Printing with Robotics, Geopolymer

Alquist 3D is aiming to revolutionize construction and infrastructure with large-format robotic 3D printing using a carbon-neutral material.

Read MoreHow AM Enables Cobot Automation for Thyssenkrupp Bilstein (Includes Video)

The shock absorber maker has responded to its staffing shortages through extensive use of collaborative robots. In-house 3D printing makes this possible by providing the related hardware needed to complete the cobot-automated cells.

Read MoreRead Next

SLM Achieves Weight Reduction for Robot Actuator

Selective laser melting made it possible to create a lighter, better performing actuator for a quadruped robot.

Read MoreAutomated 3D Printing at Evco: Composites, Cobots, Email and More

Injection molder Evco has long seen the importance of industrial automation for plastics processing. Its latest automation feat? A cobot-tended cell of 3D printers for manufacturing fixtures and customer products unattended.

Read MoreVideo: Metal AM Affects Plastics Production via Conformal Cooling

Additive manufacturing allows cooling channels within mold tooling inserts to follow the form of the tool rather than being straight drilled holes. Here’s why this matters.

Read More.jpg;width=70;height=70;mode=crop)