Large-Scale 3D Printing Supports Innovation in Construction

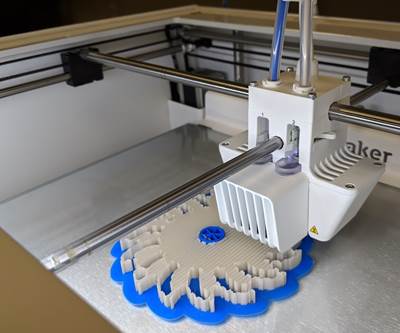

Branch Technology’s robot-based Cellular Fabrication (C-Fab) 3D printing technology builds open matrices in high-performance polymers. These structures could be the framework for better, more sustainable building practices.

“In the architecture industry, buildings have been built out of the same post-and-lintel system for thousands of years,” says Melody Rees, designer and product manager at Branch Technology. “But if you consider 3D printing as a method for construction, all of a sudden we have new methods to create buildings that liberate form and allow freedom to designers.”

This freedom is the goal for Branch Technology, a Chattanooga, Tennessee-based startup specializing in large-scale 3D printing for the construction industry. Through a process called Cellular Fabrication (C-Fab), the company 3D prints open matrices from high-performance polymers that can serve as architectural or structural pieces on their own, or as a framework for conventional building materials. Structures are typically 3D-printed in modular panels that can then be fitted together on-site. This approach to construction promises less waste, reduced labor and more innovative design possibilities.

“Many buildings have been relegated to typical rectilinear forms, but now without additional cost you can have new shapes and new forms, ultimately creating better buildings,” Rees says. In the short term, this means structures with unusual geometries that can be prefabricated in a shop setting, using as little material as possible. But over the long term, Branch Technology sees 3D printing as a vehicle for more efficient construction and more sustainable building practices.

The C-Fab 3D printing process is driven by a Kuka robot arm mounted on a horizontal track, enabling it to reach the entire 8 by 12 by 35-foot build envelope and print from various angles. Branch Technology’s proprietary print head enables the material to solidify in midair as it is extruded, eliminating the need for support structures and enabling scaffold-free features such as cantilevered or overhanging elements not typically possible with extrusion.

But 3D printing is only as good as the material it uses, which is why Branch Technology has worked with materials design company Techmer PM for the past three years to develop polymers capable of (1) supporting the large-scale projects it executes and (2) suited to its unique 3D printing process. The two companies are in touch on a weekly basis to discuss materials and requirements for upcoming projects. Two recent examples highlight the advantages of this collaboration.

Open, Cellular Structures

Branch Technology recently built the “One City” band shell for the city of Nashville, Tennessee, a three-legged structure with an unsupported span of 42 feet. The structure is composed of 36 3D-printed parts with the largest measuring 18 feet long. Getting to this design involved an extensive structural engineering process, as the initial shape for the band shell wasn’t optimized for 3D printing. As designed, the printed structure would have needed hundreds of thousands of dollars in structural steel reinforcements in order to be safe. At that point, Branch decided to take a different approach.

“Rather than a horizontal process where you go from one collaborator to the next, we said, ‘let’s do this vertically.’ Let’s go through a new process, an integrated design and structural process that also incorporates the material, and work on all of these issues together.”

“Rather than a horizontal process where you go from one collaborator to the next, we said, ‘let’s do this vertically,” Rees says. “Let’s go through a new process, an integrated design and structural process that also incorporates the material, and work on all of these issues together.”

With this strategy, Branch Technology iterated the band shell to find a design as near as possible to optimal—one that would use the least amount of material while still meeting the strength requirements. Techmer PM’s Electrafil carbon-fiber-reinforced ABS was selected as the build material for its light weight and high strength and stiffness.

“Through that process we were able to get to the best material use, to eliminate all the steel, and to use 3D printing to accomplish all the needs of the structure,” Rees says. “The design is a direct representation of the forces flowing through the structure.”

Watch the design iteration, 3D printing and assembly of the One City band shell in the video below:

Electrafil proved to be the best material for the band shell, which, while not part of a larger structure, must still withstand environmental forces like wind and the gravitational load of its own weight. Tests conducted by Branch Technology have shown that a block CMU (concrete masonry unit, measuring 16 by 8 by 8 inches) printed in this material with C-Fab can support more than 3,000 pounds, while weighing no more than 3 pounds itself.

Another recent project required collaborating with Techmer PM to develop a material specifically for the application. Branch Technology was charged with an indoor hanging garden installation, called “Nature Clouds” for Chicago’s Field Museum. The installation consists of four tiered “clouds” comprising 3,940 pounds of printed material and steel reinforcements. Together the hanging structures hold plants as well as hydroponics, lighting, theatrical fog and sound equipment with a combined weight of 12,270 pounds.

On top of the strength requirements, this structure also needed to meet building code standards for flammability, and the museum also requested that it be built of a bio-sourced resin made from a renewable resource such as corn. Techmer PM created a biopolymer derived from non-petroleum sources with natural fillers capable of meeting these requirements.

Toward Composite Construction

While these projects are pushing the limits of what is possible with C-Fab and available materials, Branch Technology sees another realm for its large-scale 3D printing capabilities. Whereas the band shell and garden are stand-alone 3D-printed structures, it is also possible to treat a C-Fab-created structure as a scaffold for more conventional building materials.

“Now we’re moving toward a composite system,” explains Rees, “where you can take that matrix and add other conventional construction materials like spray foam and concrete to create large-scale parts that will act as walls and other building components.”

“The ultimate strength of the plastic and the spray foam together is much higher than if you add up the strength of just a 3D-printed block and just a spray foam block. It acts as a true composite.”

A plastic 3D-printed block and a fill material like spray foam work symbiotically, providing different strengths, Rees explains. “The ultimate strength of the plastic and the spray foam together is much higher than if you add up the strength of just a 3D-printed block and just a spray foam block,” she says. “It acts as a true composite.”

Future projects in this vein will require more and better materials for better strength, performance and sustainability. That last point—sustainability—is key. Though the company sometimes faces pushback for using plastics, Rees believes this resistance is misplaced. Branch has been able to work with Techmer PM to develop resins that come from renewable resources such as corn rather than petroleum, and integrate natural fillers like bamboo and flax. There’s also a difference in philosophy between single-use plastic items and the kinds of long-lasting structures that Branch Technology intends to create.

“If you think about plastic items like water bottles, you use them one time and you throw them away,” Rees says. “But for these parts that we’re putting in buildings, we need them to last forever. For the first time, plastics are being used sustainably.”

Related Content

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

Read MoreBig Metal Additive: The Difference Between a Shape and a Part Is Quality

Preparing to scale directed energy deposition to ongoing full production is not a technological challenge: DED is ready. But it is an organizational challenge, says the company founder. Here is what it means to implement a quality system.

Read MoreDMG MORI: Build Plate “Pucks” Cut Postprocessing Time by 80%

For spinal implants and other small 3D printed parts made through laser powder bed fusion, separate clampable units resting within the build plate provide for easy transfer to a CNC lathe.

Read More8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreRead Next

Additive Manufacturing and Sustainability Go Together — Here Is Why

3D printing enables sustainable production through recycled materials, end-of-product-life-cycle solutions, and helping to realize eco-friendly products.

Read MoreA Circular Economy for 3D Printed Plastics Starts with Material

When the greatest share of a product’s environmental impact comes from producing its feedstock, selecting the right material is critical. For 3D printing and manufacturing in plastic, biopolymer could be the first step toward a more sustainable model.

Read MoreAdditive Manufacturing Will Aid And Accelerate The Circular Economy

A circular economy links material, design, manufacturing, product and end-of-life in a continuous, sustainable loop. This special report illustrates the roles for 3D printing every step of the way.

Read More

.jpg;width=70;height=70;mode=crop)