Applying Material Like Toner Promises AM at Speeds Like Injection Molding

The Stratasys-founded company Evolve debuts its STEP technology for production-scale additive processing.

When Evolve Additive Solutions Chief Business and Marketing Officer Bruce Bradshaw refers to the Evolve’s new “STEP” technology for additive part production, he is careful to avoid the term 3D printing. The technology is for high-speed, high-volume additive manufacturing, nothing like the one-off applications where 3D printing began. But the irony in avoiding this term is that STEP has as much in common with actual printing as any additive system so far. The technology achieves high-speed material layering by applying polymer onto rollers like toner in a document printer. Indeed, to understand the concept of STEP is to realize that many of the additive technologies to date have been performing essentially like dot-matrix printers. By contrast, here is an approach to additive that is both metaphorically and literally very much like a laser-jet printer.

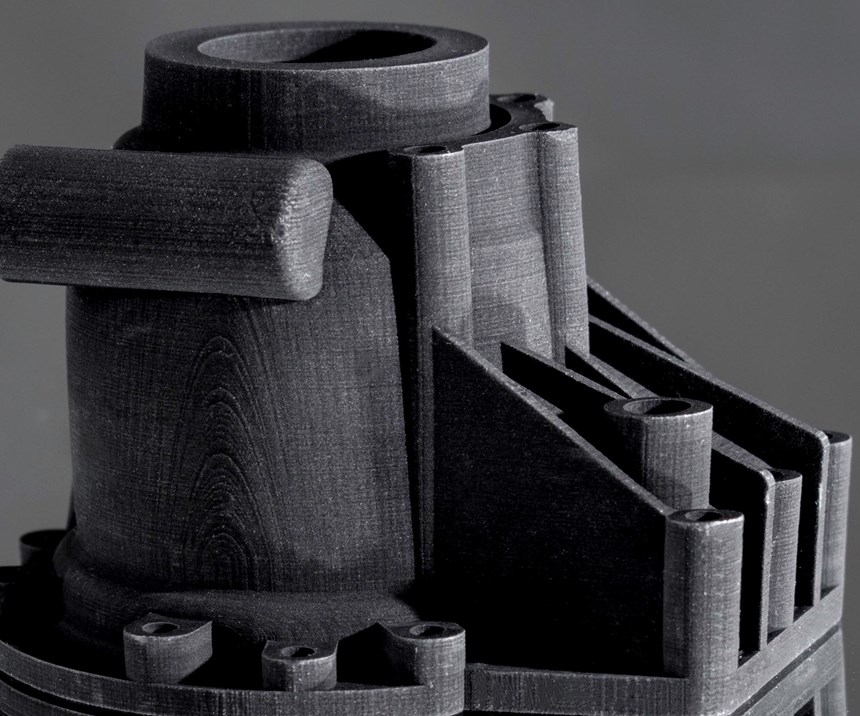

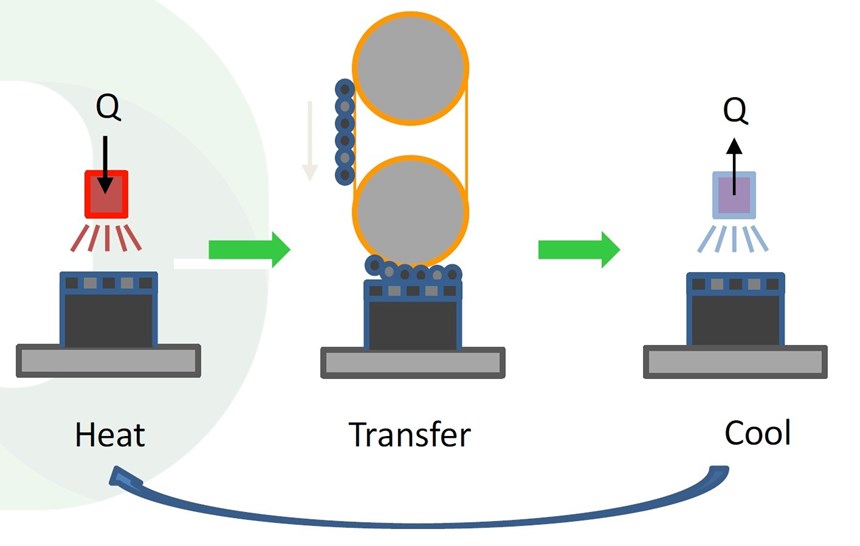

In the STEP (Selective Thermoplastic Electrophotographic Process) technology, the material layers that are applied like toner are delivered by belt onto a preheated part that is moving at a matching speed. The belt carries an entire layer at once, precisely meeting the part as it moves in a straight line beneath the belt on a conveyor of its own. Thus, in applying material to part, there is nothing like a nozzle or beam that moves through one small area at a time. Rapidly delivering each layer in this way allows for build rates unlike previous additive processes. The first machine model developed offers a build chamber measuring 24 × 13 × 6 inches. One layer across its 24 × 13 area can be applied in 4 seconds. Filling the entire volume with parts—however many parts can be fit into that space—takes 3 hours.

Established 3D printer maker Stratasys developed the technology to its current point, then spun it out into Evolve, a separate company in which Stratasys is a minority owner. Steve Chillscyzn, co-inventor of the technology, is the company’s CEO. Establishing a separate company was necessary, he says, because realizing the full potential of the technology will ultimately require the investments of more stakeholders and the participation of more partners than the control of one parent company would permit.

The plan is to fully commercialize the technology in 2020, he says. Evolve is announcing STEP this year in part because it is searching for beta testers, and in part because the technology is a solution for (among others) large companies that will need time to recognize that this solution is coming and adapt their plans.

Bradshaw says the capabilities of STEP are more comparable to injection molding than to other additive processes. Particularly to short-run injection molding. STEP provides a way to obtain a 2,000-piece run of plastic parts within one day, versus the weeks of lead time that might be necessary to wait for mold tooling. And because the mold is absent, the new technology also delivers a cost per piece at this quantity level that is lower than molding.

One other way the process is comparable to molding is this: The process can produce parts missing the layer lines typical of 3D printing. STEP mates heated layers to a heated part, producing fusion that is more complete than in a process such as FDM.

Candidate materials for STEP are the same polymers available for injection molding, the company says. However, delivering the materials as toner requires materials-engineering techniques proprietary to Evolve.

Meanwhile, some of the part-design possibilities are very new. The STEP process has parts passing conveyor-style under the belt applying material, meaning the conveyor could also carry parts—including incomplete parts—to separate processing stations. For example, the unfinished part could pass to assemblers or robots for quick installation of electronics before being sent back into the additive build. The result would be low-cost solid parts with electronics sealed inside.

One other possibility comes right back to the technology’s origins in conventional printing. A laser-jet document printer can apply not just one toner, but several. Similarly, the STEP machine (even in its current alpha form) has multiple print heads. This can allow for multiple colors in the part, but an even richer possibility is the chance for multiple materials. Various different polymers applied at the voxel-by-voxel level could achieve combinations of properties unobtainable in any single material alone. Thus, the technology is potentially a competitor to injection molding in some applications, but this misses the full case for it. At its more powerful extreme, the technology offers a means of realizing parts that were previously unthinkable, then manufacturing them at production scale.

Related Content

VulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

Read MoreVideo: 5" Diameter Navy Artillery Rounds Made Through Robot Directed Energy Deposition (DED) Instead of Forging

Big Metal Additive conceives additive manufacturing production factory making hundreds of Navy projectile housings per day.

Read More3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

Read MoreBeehive Industries Is Going Big on Small-Scale Engines Made Through Additive Manufacturing

Backed by decades of experience in both aviation and additive, the company is now laser-focused on a single goal: developing, proving and scaling production of engines providing 5,000 lbs of thrust or less.

Read MoreRead Next

Update on Evolve: Ensuring Repeatability, Reliability and Speed for Scale Production

Engineering the machine and process to work as consistently as production hardware ought to perform is where the company says its efforts have been focused.

Read More3MF File Format for Additive Manufacturing: More Than Geometry

The file format offers a less data-intensive way of recording part geometry, as well as details about build preparation, material, process and more.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read More