Articles

Rounding Out the Circular Economy With Material Take-Back Programs: AM Radio #6A

One of the most difficult steps in the circular economy is going from product back to new material. On this episode of AM Radio, Julia Hider and Stephanie Hendrixson discuss how material take-back programs can help solve this challenge.

ListenVideo: What is the Manufacturing Demonstration Facility at Oak Ridge National Laboratory?

This industry-focused organization within the Department of Energy helps manufacturers make use of advanced technology, particularly 3D printing. One of the group’s leaders describes how companies work with the MDF.

Watch3D Printed Turbine Blades for More Efficient Power Generation: The Cool Parts Show #35

Blades made through additive manufacturing promise to let turbines run hotter, and therefore generate more power without increasing in size.

WatchAM for Production: Where Conventional Lessons Do and Do Not Apply

As RMS has grown its additive manufacturing division, it has discovered which principles of subtractive manufacturing apply to additive, and which do not.

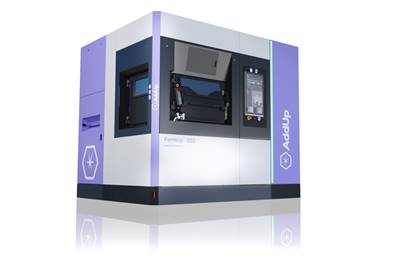

ListenPrecision LPBF Improves Watch Component Part Performances

Partnering with AddUp has enabled watch part maker Kif Parechoc to use laser powder bed fusion to manufacture parts with improved mechanical performance using less material.

Read MorePlatform Solution Supports 3D Printing's Pivot into Additive Manufacturing Production

The GrabCAD Additive Manufacturing Platform introduced by Stratasys integrates design, print preparation, order management and third-party software to help bring about AM for production.

Read MoreGetting to a Circular Model for Metal Powders Makes AM More Sustainable

6K’s UniMelt process offers efficiency and control in the production of metal powders for additive manufacturing. But more than that, it is a home for unused and oversized powder, metal scrap and more that can close the loop on metals.

Read MoreRecapping the 2021 Additive Manufacturing Conference + Expo: AM Radio #5

The program covered everything from tooling to personnel challenges involved in implementing additive. Peter Zelinski, Stephanie Hendrixson and Julia Hider recap the event.

ListenThe Cool Pen Show! (The Cool Parts Show Bonus Episode)

3D printing provides a means of economical U.S. production for a low-cost product.

WatchSimulation Prevents Expensive Hybrid Manufacturing Errors

Errors while finish-machining additively manufactured parts can waste production time and tens of thousands of dollars. Vericut has enabled Keselowski Advanced Manufacturing to avoid these mistakes.

Read MoreReshoring Manufacturing With 3D Printing: The Cool Parts Show #34

Wet-dry vacuum maker shifts to additive manufacturing for first entirely U.S.-made product, a jackhammer accessory. More U.S. production to come via 3D printing.

WatchWebinar: Innovation through Digital Manufacturing

How can you compete and stay competitive? We need to be in front of supply chain shortages, adapting to working from home while maintaining collaboration, and reducing our environmental impact. Lead the change and reach new heights.

Read More