7 Lessons From General Atomics on AM for Aircraft Part Production

A manufacturing leader overseeing the way additive manufacturing is transforming unmanned aerial systems (UASs) offers observations about succeeding with 3D printing as an aircraft production process.

An article we recently posted details the extent to which additive manufacturing is transforming production for General Atomics, developer of unmanned aerial systems. For this company’s larger planes, AM has cut over $300,000 from the part cost per aircraft and has saved over $3 million in tooling cost. And for a forthcoming smaller plane, extensive use of AM has replaced what would have been 180 parts with four, and will allow a complete plane to be built in a single day. Making an unmanned craft that historically has flown in uncontested airspaces allows AM to be incorporated more quickly than it can be qualified for planes carrying people, but still, these savings point to what will eventually be possible with AM for aircraft production in general.

Steve Fournier, senior manager of the Additive Design and Manufacturing Center of Excellence for General Atomics Aeronautical Systems Inc., was quoted extensively in the longer article. But he had more to say on what the company is learning about various industrial AM processes. Here are some additional points on additive for aircraft part production:

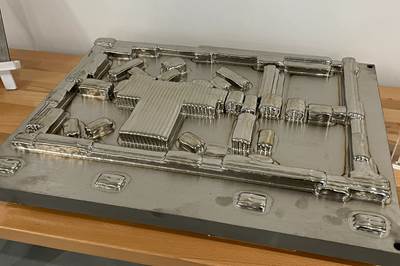

DED minimizes the amount of metal that must be lost to machining. This landing gear component was 3D printed near to net shape by Norsk Titanium, allowing for significantly less material use (and material waste) than if this part had been machined from a block-shaped billet. Photo courtesy of General Atomics.

1. Directed energy deposition (DED) is a valuable part-making option. The justification for this process is in buy-to-fly, or minimizing the proportion of material purchased that does not make it into the plane. In aerospace, use DED to obtain parts closer to net shape so less machining is needed. “In titanium, we can’t waste chips,” he says.

2. The price of a production-ready AM part is in its ecosystem cost. That is, the cost of making it, plus all the costs around this related to sourcing, handling, shipping and inspection. The ecosystem cost is the only way to accurately answer the question, “What will this AM part cost us versus making it the conventional way?” Looking at the total cost of manufacturing is the way General Atomics remains true to an internal motto to “3D print because we should, not because we can.”

3. AM for part replacement is almost never about just one part. Typically there is a family of parts that can benefit from AM instead, sharing a similar AM ecosystem. Or there is an entire subassembly, of which this part is a member, that can be replaced by additive.

4. The case for AM replacing parts made through composite layup is in the labor content, tooling requirements and validation that are avoided — and the last of these is significant. An aircraft duct made of composite is an assembly of multiple composite parts. To make each one, a tool is needed, and that tool has to be measured to make a piece that also has to be measured. In composites applications such as this, “40% of total part cost is typically measurement and quality assurance,” Fournier says.

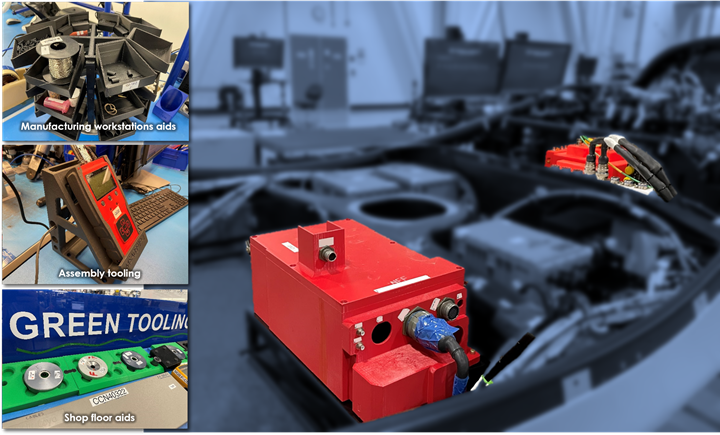

GA provided this composite of various shop aids produced through 3D printing. As empowering as AM is for the design and capabilities of the end-use product, the ongoing empowerment of the production process is another use that shouldn't be forgotten.

5. Even after AM starts to succeed for end-use part production, AM also needs to keep developing and providing 3D printed shop aids to assist internal manufacturing. “You are leaving a lot on the table if you don’t do this,” he says.

6. In AM, often titanium is cheaper than aluminum because aluminum will need heat treatment to meet material property requirements. This source of savings can be hard for design engineers to see at first. They are in the habit of resisting specifying titanium not just because of the raw material cost, but also the work of machining it — a difficulty AM largely avoids.

7. Of the many boxes to check to get to an AM production process — including materials allowables and equivalencies; supply chain qualification; relevant software tools; production-ready hardware and more — the box that is the costliest is the industrialization and qualification methodology. This includes all the relevant risk reduction testing and demonstrations. The higher the criticality of the part, the more lengthy and costly this consideration becomes.

Related Content

Video: Enabling the Digital Inventory with 3D Printing

Würth Additive Group’s Digital Inventory Service (DIS) platform aims to make it easy and secure to store part files in digital inventory, and deploy the data for manufacturing as required. See a demo in this video filmed at IMTS 2024.

Read MoreCombining Metal and Polymer for Better 3D Printed Tools

Applications prone to wear call for more durable tooling than 3D printed polymer alone, but full metal is not always necessary.

Read More3D Printed Calibration Fixtures for Ultrasonic Flowmeters

Calibrating industrial flowmeters requires temporarily attaching equipment to pipes to check the flow and make adjustments. Emerson shares how 3D printed fixtures can simplify the connection and make calibration faster, easier and more accurate.

Read MoreMedical Molder Relies on 3D Printing to Speed Development of Inspection Fixtures

Medical molder Medbio uses FFF and SLA 3D printers in designing (and sometimes producing) its inspection fixtures.

Read MoreRead Next

At General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read MoreHow Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read More